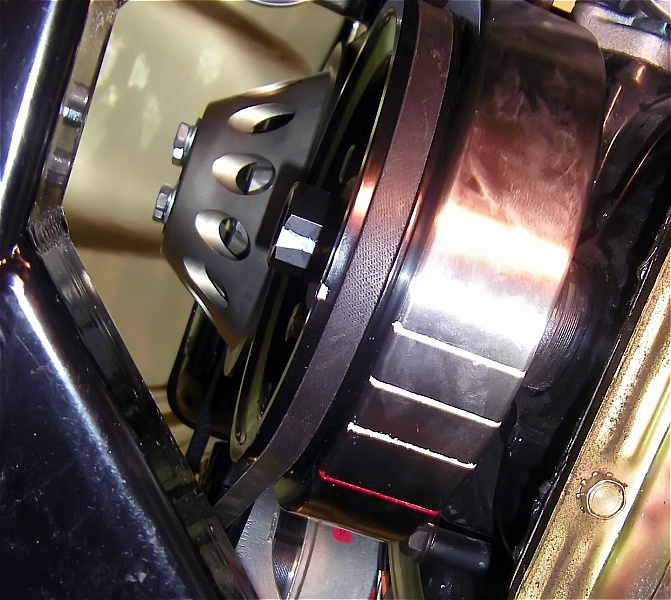

I tightened, torqued and loc-tited the water pump pulley, crankshaft pulley and double checked the alignment before tightening up the belt:

At the recommendation of one member who had a

really bad experience with the outside of a dampner slipping, I added a white line on the pulley, and a white line on the crank bolt, that all line up with the TDC line.

Doing that makes it pretty obvious if anything has slipped or loosened -- especially under the timing light. I'm not sure where that original POS dampner came from, but I could tell from how it separated that it was about half a dozen degrees different than the new ROMAC when I put one on top of the other. I'll paint a line on the timing marker next week, after I find my piston stop, that is spot on for TDC -- it's going to be roughly where you see the 10BTDC white line in this little video I shot. You can see how the TDC line aligns with the pulley line that aligns with the bolt line. Here's the vid:

Video of the Marks

I think that pretty much does it. Thanks to all for their input and help.

EDIT -- the follow-up thread on using the piston stop to find TDC can be found here:

How big an issue are slipping balancers?