OK, hereís what I have so far. To me it looks like Mike called it a few posts back. When I bought this cam back in 08 I remember getting a cam card with it but Iíll be damned if I know where the heck it is. And as much as it pains me to say it, I probably gave the machinist errant information. At any rate, when the machine shop assembled the heads, the springs were inadequate for the cam even then but they didnít have the cam. Fast forward to today and when talking with the machinist he wanted to know the cam specs because it looked like the keepers had been crushed on that valve and the same thing had started on another as well. He tested the spring pressure at 80# installed @ 2Ē. Now for the good part, when talking to KC they found my info but didnít know exactly which cam I had. So going off of what info they gave me I measured the lobe lift with a dial indicator at lunch today and came up with right at .370Ē which gives me .651Ē with a 1.76 rocker ratio. I was under the impression (senility?) that the lift was well under .600. With this much larger cam my machinist believes that the valves had to be bouncing to cause the damage to the keepers and has ordered some springs to give more like 160# on the seat. Brent and other have asked about the keeper/retainer angles and they are 7 degree on each. Since these are being changed anyway he thought it would be good to go with 10 degree parts as heís had better results with them. These should be here Wednesday. He believes that this bouncing could also have caused the rocker adjusting nut to come loose. Having never seen that before, hey, makes as much sense to me as anything else.

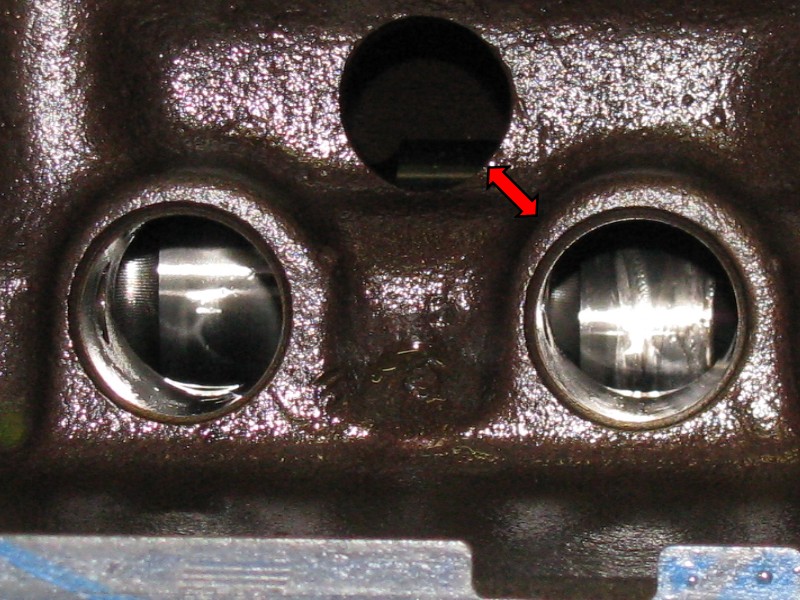

On to the f-ing nut. I finally found the moving part that apparently pulverized the little thing. This evening I wanted to do whatever I could to make sure that I wasnít going to have any more problems on assembly. So I had my son slowly rotate the crank a quarter of a turn at a time while I used a light down the lifter bores. This was the second time that Iíve had the lifters out and looked in all the lifter bores but the first time I had someone rotate it while I looked with a good light. Hereís what I found;

Those marks on the cam lobe are only right at the nose of the lobe which is probably why I missed it before. Looking at any other place on that lobe it looks fine and the lifterís roller shows absolutely no hint of anything wrong, even under magnification. So Iím thinking that it couldnít have run for very long at all after that happened.

Going by the forensic evidence It appears that:

the nut was jarred/broken loose by the valve bounce,

fell through the opening between the intake and head,

went down that hole over the cam,

got swung around by the cam lobe,

then crushed between the lobe and the block,

and fell the rest of the way to the pan.

Prolly got kicked a time or two by the recip assy on the way down too.

Well, thatís what I come up with anyway.

Iíll probably know more tomorrow when I get the cam out. You guys see any lapses of logic?

Steve