Well here it is the middle of October and I’ve found myself making a mental switch to the long cold Winter ahead of us here in the North East. With it having been nearly 2.5months since entering an update in my ownership log for 2124, I thought I would give ya’ll a look-see into what’s been going on.

Early in the Summer this year, a good friend of mine and I were resurrecting the idea that he should sell his fully auto-x prep’d ’04 Subaru WRX STi to me and that he should move on to his next auto-x car – a C5 Z06. ’04 was the introductory year for the STi in the States and is the year I believe to be the most “pure” and “purposeful” towards it’s true intent. I fully expect these cars to be rolling across the Barrett-Jackson stage in another 25yrs as I gaze into my crystal ball, but probably not this one as it is being fully enjoyed as a foul-weather weekend warrior, and a reliable daily driver during the weekdays. So the first of September, I took possession of this car and out of the kindness of my heart, I am letting my good friend finish his points season out with three auto-x events left to go. (he’s leading at this point!)

Requisite crappy cellphone pic:

So re-winding a bit, it was the middle of August when there was a couple of weekend events happening. One was the final Winchester auto-x held by our local club, and the second was an annual car/hot rod show held at a local public recreation park. I thought it would be very nice of me if I suggested to my dad that he take ERA2124 to the car show and spend a little time at a show-n-shine, meanwhile, I would go to the Winchester event getting familiar with the soon-to-be-mine Subaru. Seemed like a win-win to me. Preparations were made, I delivered the car to Dad, and learned of his cunning plan to clean the engine bay of the cobra before taking it over to the show. I was later told that he followed every precaution to the letter as to make sure no moisture would keep the car from starting after the detail. After a 3hr effort, he started the car up on the first try and let it get nearly up to temp, shut the car off, took a well-deserved shower, and upon returning to the car with an hour to show-time, found that it just…would….not…start. Apparently somewhere in the process of cranking, the starter gear had a fight with the flywheel ring gear, and the ring gear lost a couple of teeth..4 to be exact….a group of three and a lone tooth further round the circle to be perfectly precise.

Well, the car did eventually start, but Dad never made it to the show….and I felt bad for him. After hearing the story about what happened and making my evaluation of the damage, I took the glass half-full approach and decided that maybe we could get by for the rest of the driving season with the few missing teeth. Trouble was, the starter and the ring gear from West Virginia weren’t getting along and hitting the switch produced the most terrible racket. 4 missing teeth quickly grew to 10 and I decided it best to leave the car sit until I could get some time to plan my approach and make the needed reparations.

So, fast forward now to this past weekend. After studying the ERA assembly manual, I decided to ditch my early planned approach in pulling the engine/trans out of the car together for just simply removing most of the car’s inside bits and pulling the trans from the interior of the car. Several early mornings were spent prior to work preparing the car for this event, a half day of vacation was scheduled, my good friend did the same, and we made a go at it. What follows is a little pictorial record of the first half of the procedure. When we were all through working on Friday, the ring gear was replaced, a new rear main seal was installed, the trans was buttoned up, and the hydraulic TOB was bled and tested functional. It was a good result for sure! Here are the pics:

This first pic shows the access to the transmission once the transmission tunnel is removed from the car. It can’t be dropped as the manly ERA frame has a X brace between the two frame rails adding torsional stiffness and providing a mount location for the rear of the trans. There are two options for removing the trans, splitting it from the engine and doing as we did, or pulling it out attached to the engine.

Once we removed the 105 lb transmission (TKO600), the next step was to remove the Mcleod bell housing. This pics shows the clutch pack and flywheel:

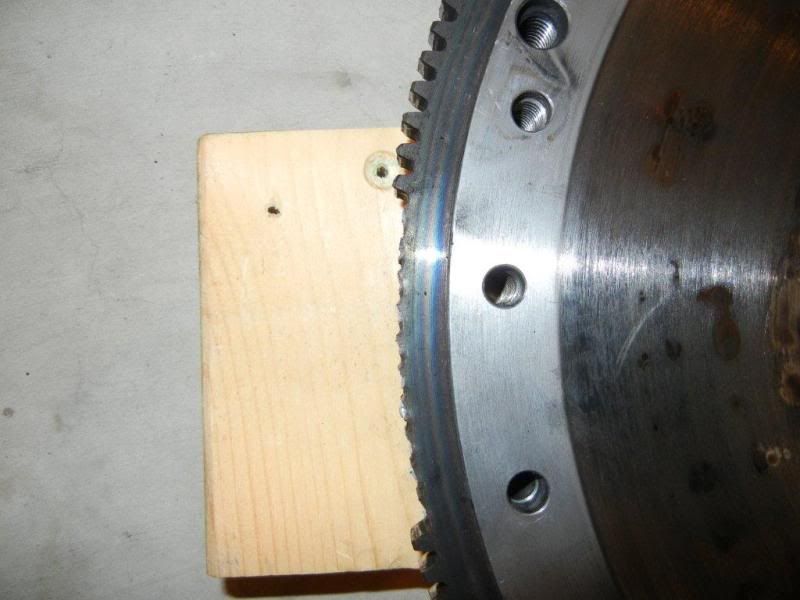

My flywheel ring gear was originally a 157 tooth unit before being reduced to 147 teeth. I borrowed a nice fat brass drift from a friend at work and proceed to use it to knock the old ring gear off with the aid of my lead 6lb American Hammer – worked like a charm. The new ring gear, an ATP piece, was sourced from Amazon and arrived at my door a full 1.5days after ordering it for a total price of less than $20 shipped! Amazon is amazing. This is what the old ring gear looked like after its battle with the starter:

And this is what was found in the clutch dust and engine

oil cocktail at the bottom of the bell housing:

The next step was to fit the new ring gear to the flywheel. Folks tend to use two approaches to this, the heating-with-a-torch approach, and the wife’s oven approach. Since I didn’t have the required acetylene torch, I made nice with my wife and got some time scheduled in the oven, put in the new ring gear, and set the oven on Bake @ 400 degrees.

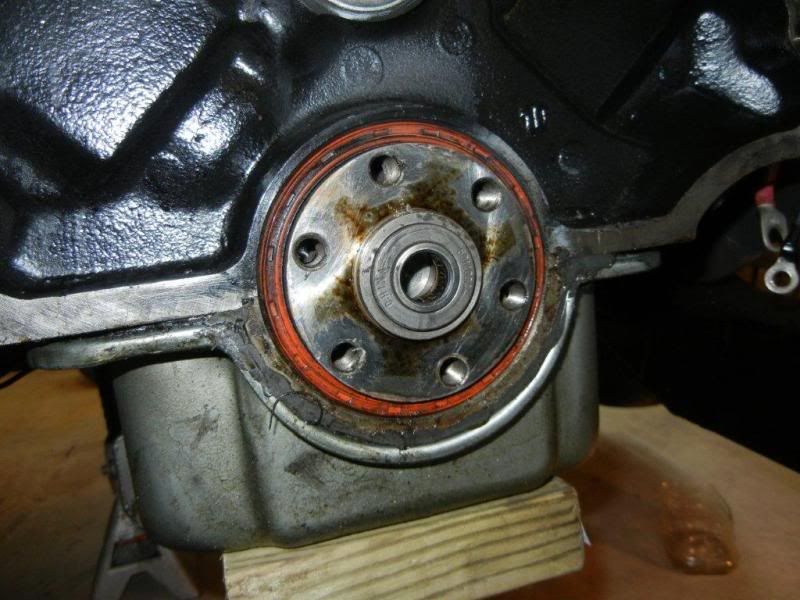

While that was getting up to temp, I decided to replace my rear main seal that had a bad habit of peeing on my garage floor. Once the flywheel and backing plate was removed, it looked like T&L engines added some crap silicone behind the

oil pan gasket in an attempt to use the backing plate to help seal things. So at this early stage, I’m not sure if the new seal was the root cause of the leak, or if I actually have an

oil pan sealing issue, but time will tell on that. I was sure to clean the main cap and crank sealing surfaces really well and pack the new main seal with lithium grease before the install. All seemed to go in nicely. Here is a pick of what was behind the backing plate before replacing the main seal. BTW, this engine has less than 12K mi on it.

So, back to the kitchen. Long story short, the oven didn’t work. Even at the max temp of 500 degrees, there just wasn’t enough expansion on the ring gear to get it to easily slip over the flywheel. So without wasting too much time, we loaded the parts up and I found a neighbor nearby that had appeared to be already well into his Friday ration of Pabst Blue Ribbon and agreed to use his torch to help me out. $20 later, I was a happy camper. (said he’d be using the $20 to buy more beer).

So install was the reverse of removal and as the car sits now, I’m two seats and an exhaust system away from a road test. Fingers crossed that all will be well. Now that I have the top and side curtains, I hope to squeeze as much out of the remaining driving season as possible.

Until next time,

- Allen.