Quote:

Originally Posted by bobcowan

AFAIK, the specs you want don't exist in an off the shelf solid roller cam. I'v searched, and haven't been able to find one from any manufacturer.

The wide LSA is important for Webers, or any IR intake system. That keeps overlap to a minimum. Since you don't have a common plenum, the overlap will create the fuel cloud from reversion.

I rtan a cam similar to this one (hydraulic roller) in my 427W. It makes great power, and pulls like a freight train all the way to red line. It makes power pretty much everywhere.

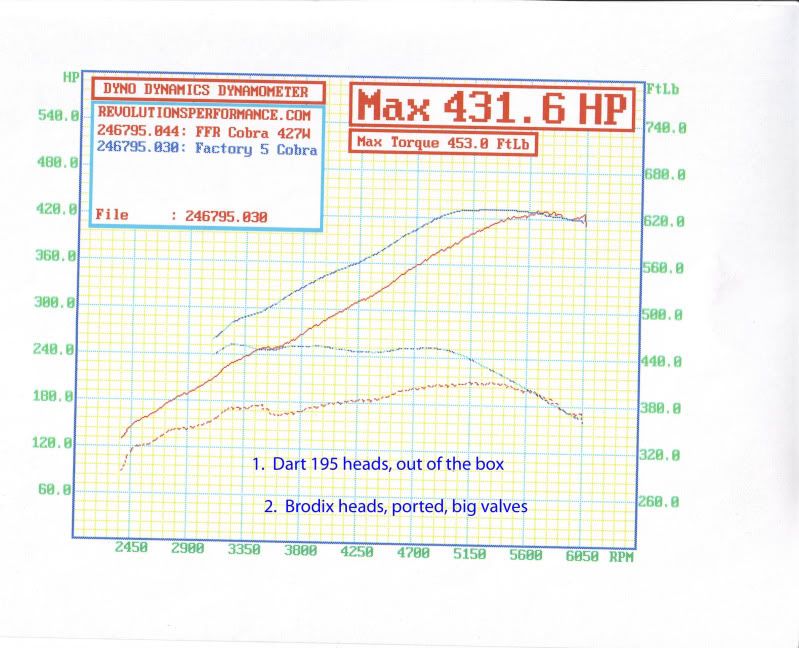

Use caution with your head selection. I'm using some Dart Pro-1 195 heads. They have a 2.02" intake valve. A couple of years ago I tried a set of Brodix heads, with 2.08" valves. I lost all my low end torque. The intake was too big for the throttle body, and the intake charge lost it's velocity. The intake valve should not be larger than your carb/TB bore.

Your carb bores are 48mm. Your intake valves are 50mm. You might have a mis-match there. The blades and other stuff do take up some space, so you might be OK. If you haven't purchased your heads yet, you might reconsider that choice.

|

BobCowan - can you discuss this a little further. I found info that states the 48's can flow 330 cfm per throat. Your 427w is still using a 51.3 mm intake valve - ideally a 1.89 inlet valve diameter match the 48 bore.

My understanding is the optimal intake valve size would be .5 to .56 of the bore (perhaps old school so it may discount all below).

On a 4.030 bore a 2.015 - 2.25 would be the optimal inlet diameter based on the premise above. Clearly the 48 is not adequate once the inlet valve size crosses a threshold (Graph Above - and thank you for posting).

You stated you thought you could gain a little more by resizing the intake again to 2.05 yet this would be slowing the intake charge at the valve as you stated. Am I to conclude there is a narrow margin where you can run the intake valve a little larger and the fuel separation has a negligible affect? If so, does displacement somehow play a role? Why would it work on a 427 and not a 331 - the throttle bore and inlet valve dia are the same on both.

A 1.90 inlet is the closest match for the 48. Why would you want to go up (2.05) instead of down (1.89 optimum) if your were to spend the cash?

I want to order my heads, but want to make the best decision. I found some specs for the 289 Hipo and it seems they started with 1.678 inlet and ended at - 1.788" so the 48 was a no-brainer. I do not know what the FIA's and USRRC cars ran. Would be interesting to know.

I want to order my heads, but want to make the best decision. If I can get away with the 195's that is the way I want to go as the flow rate really hooks up the the 48's 330cfm capability. However, if for some reason 48's and 2.02 inlets are a mis-application on a 331 (based on diameters they are) then I will limit to 1.9. Why does it work on your 427? Would it make more with 1.9? Why not?

Allen - have you had your beauty on a dyno? If so can you share some numbers?

I appreciate any input.

cliff