Quote:

Originally Posted by KevinW

My frustration comes from the struggle each time to fit the back 2 header pipes each side of the FE which are very close to the footboxes (2 hours to fit 4 ARP bolts and the gasket). Are there any clever ways to do this? A friend of mine told me to jack the car and work underneath it. I so hate doing this.   |

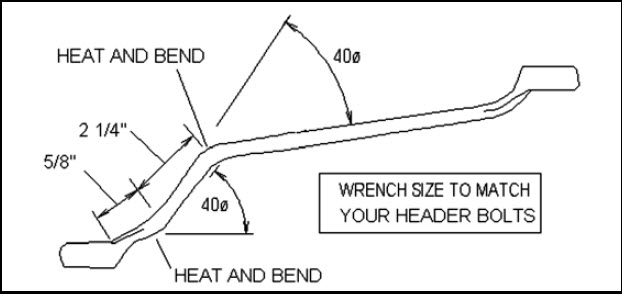

You only have two choices, come down from the top through the open hood, or come up from the bottom of the car. Just make sure your car is properly secured with stands so you don't get hurt. There are no "tricks" to getting to the bolts. Having the proper tool helps, though. ERA recommends the "heat and bend" method to fabricate a header bolt tool. Like this: