Sneaking up on it...

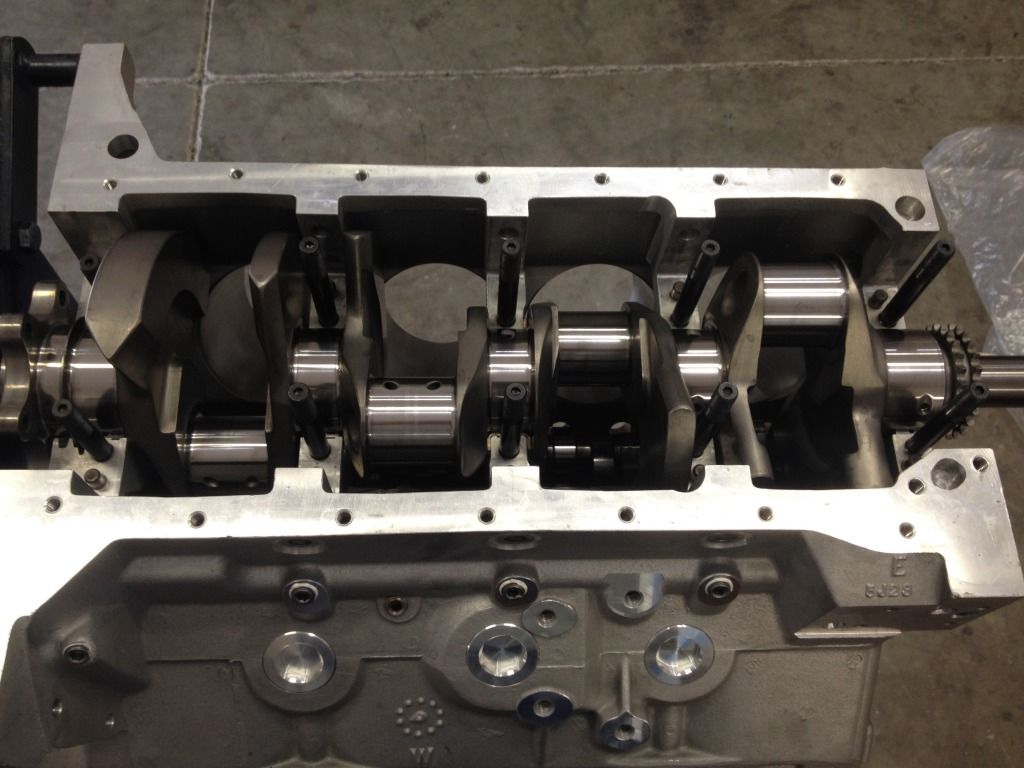

One of the pluses of ordering a custom crank is that you get to specify the bobweight. When the engineers lay out the counterweights, they can design them so it will make it easy to balance. This one just took one small piece of metal to internally balance.

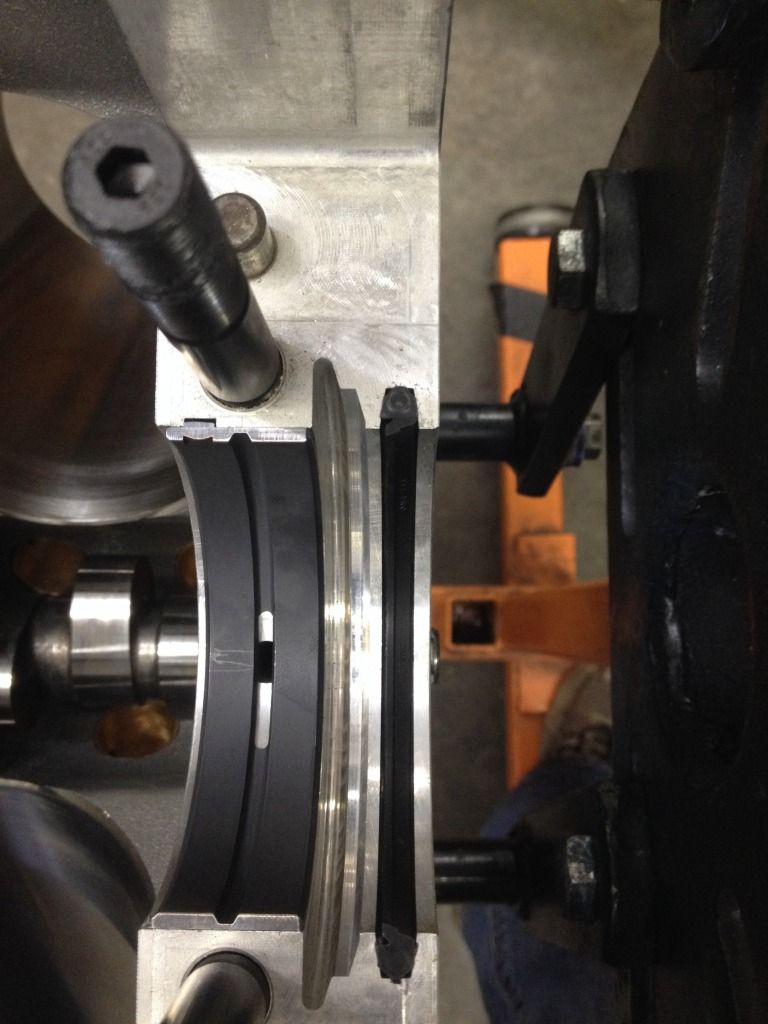

These Oliver rods torque at 30 lb-ft plus 44 degrees, then you check stretch. This torque wrench wasn't cheap, but it keeps track of lb-ft, then keeps track of how many degrees you've pulled the fastener....

[/url]

Very time consuming process....torquing, then checking stretch, then modifying if necessary, then recording all the measurements.

I forgot that I didn't have any fuel pump eccentrics machined. I use the Ford Racing timing sets and the Ford Racing one piece eccentrics. If you don't cut them down, they can rub on the timing cover. I dropped off several yesterday to have cut down, so once I can pick them up, the timing cover,

oil pan, balancer, etc. can go on.

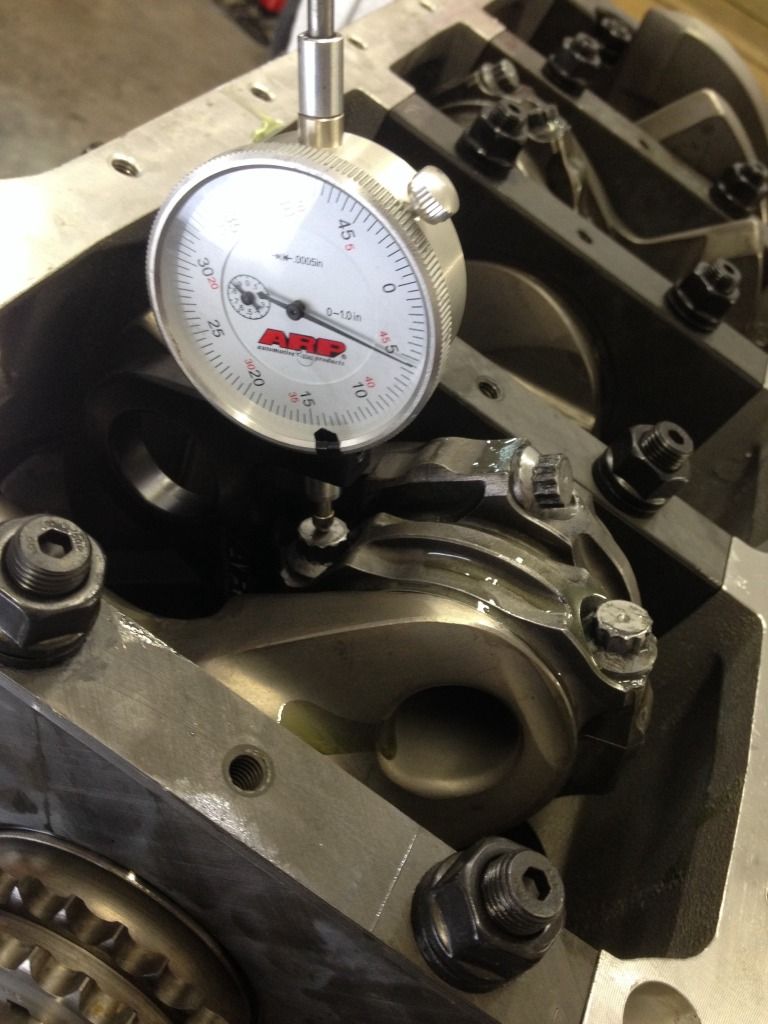

I also spent some time mocking up the valvetrain and adjusting the stand heights to get the most efficient action at the valves.

Progress....