Replacement of old, leaking Slave Cylinder…

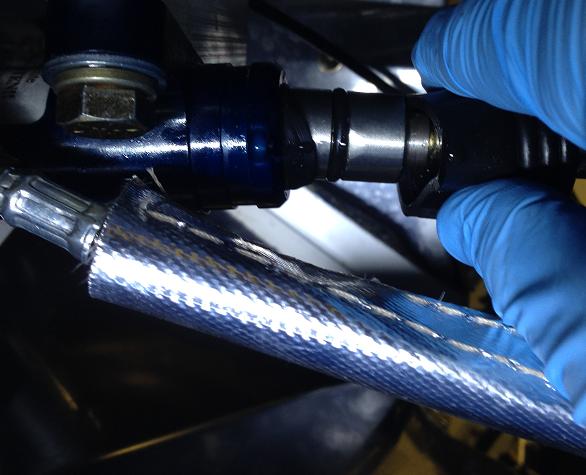

My master cylinder is a Wilwood ¾” bore with 1.4” throw. I called Mike Forte and he sent me a ¾” slave kit with a machined bracket for a Tremec, adjustable bracket and heim joint push rod assembly for the clutch fork and ¾” bore CNC push slave cylinder.

When I first installed it and pushed the pedal, I completely blew out the piston. I mean OUT. The piston was sitting on the lip of the slave opening, pushing the clutch further in than it ever had.

I talked to Mike. He said I should adjust the pedal for less travel (along with a new ¾” CNC slave). Made sense, but if I did, the clutch pedal would be sitting further into the foot box when not being touched. The clutch and brake pedals wouldn’t be ‘lined up’ anymore. Not a huge deal but there’s more…

For $#!ts and giggles, I installed the CNC 7/8” slave that I was originally going to use (didn’t know Mike’s kit came with a slave), so I installed the 7/8” slave just to see. I understand the difference in master/slave relationships, after all, I’m married (ba-dumm, pshh). The feel is great but the slave pushrod is traveling less distance than before. Now it’s got about 1” travel [corrected from original post] compared to the original slave’s 1.125” of travel (the original slave was a generic p/u truck 7/8” bore, so I’m not sure how I EVER got 1.125” of travel, but I did).

Hear me out - it appears to be working fine. Shifts fine -TKO600 just as clunky as before

. The pedal feel is great. The pedal is where I want it. The action in the clutch is at the last inch of pedal travel. With the car on stands, engine running and in gear and the clutch in, the wheels don’t move. With the car off, in gear and clutch in, I can freely move the wheels. Wouldn’t you say I have total disengagement and no dragging? Am I over simplifying it?