Got the crank back and the new plugs installed. Cam is degreed and cam timing adjusted, piston to valve clearance checked, pistons/rods installed, and heads are bolted on.

Cam is on a 108 LSA and was ground with 2 degrees of advance, so ICL should have been 106. I actually wanted it on a 104 ICL, so I instinctively put the crank gear on the 2°A position and degreed it. Turned out, when I degreed it, it came in at a 102 ICL.....so I put the crank gear back to the zero position and it came in at 104.

That's why you always degree a cam. It also helps to degree the cam with both methods as some cams have asymmetrical lobes and the ICL method doesn't always work.

The cam thrust clearance was checked and was a little tight for my liking at .002", so a few seconds with some persuasive massaging opened it up a couple thou more. Cam bolt was torqued and I stuck a fork in that part.

Heads were bolted on and torqued. I'll retorque tomorrow.

With the Crower SBF EDM lifters and T&D rockers, pushrod length came in at 9.375" and I'll order those from Trend on Monday. I'll snag a set of 5/16" .105" wall pieces.

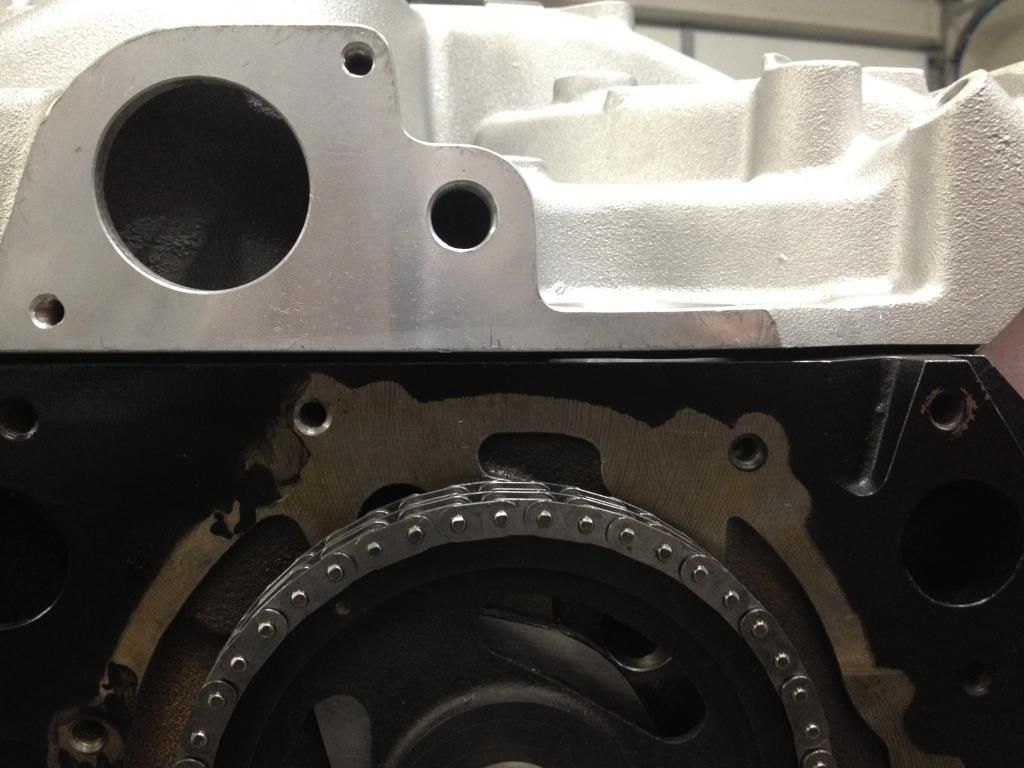

I also took a second to test fit the intake, which needs to be done with each and every build. You will usually find that they just don't fit out of the box, due to dimensional issues or issues with straightness.

I test fit without the intake gasket first, just out of habit. It usually turns out that the intake flanges need to be cut.

And.......just so turns out to be the case on this one too. Look how beautiful the ports line up and the geometry lines up without a gasket.

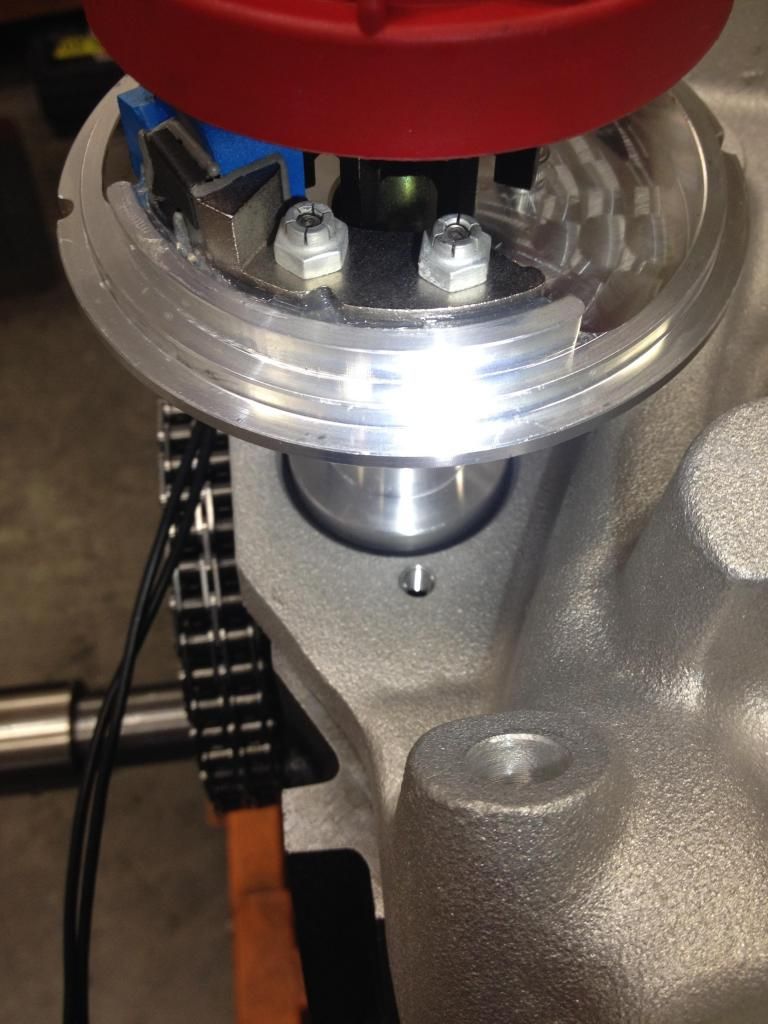

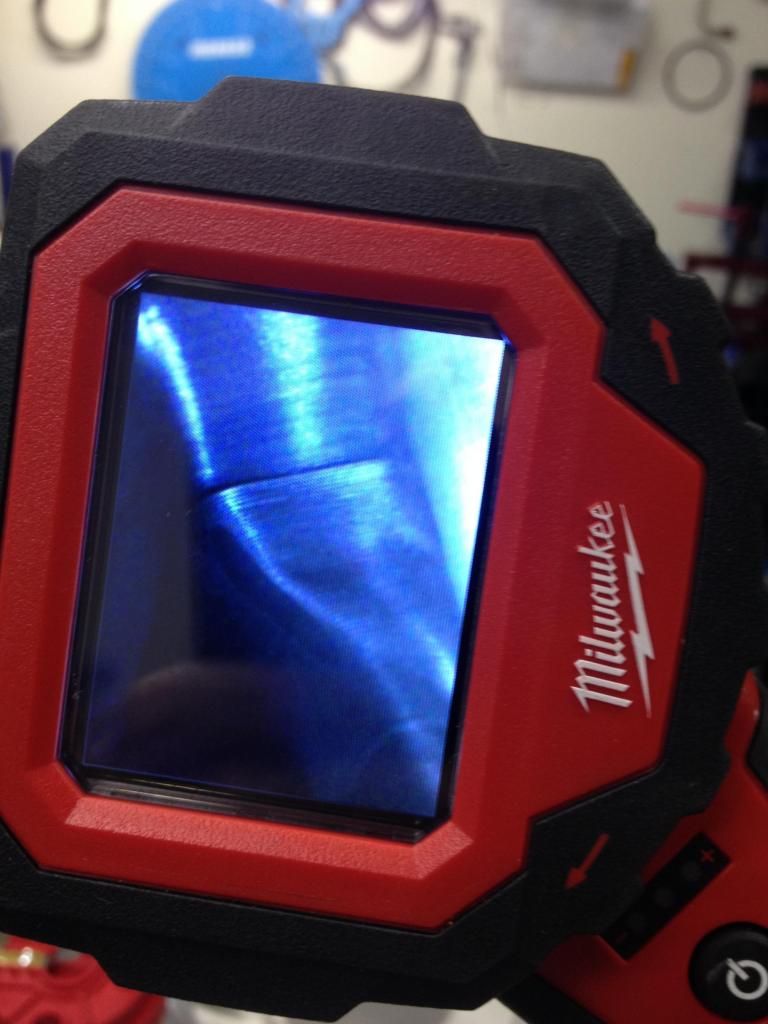

On a dual plane intake, it's almost impossible to see how the ports line up without some help. If they don't match the heads, you can end up with the intake charge literally hitting a wall, which can end up creating some reversion and some loss of power.

Luckily, years ago I invested in a video borescope. And, as you can see, without the gaskets, the ports line up just beautifully.

In addition, if times get tough, I can do some colonoscopies on the side....

The intake will get milled this week, .060" needs to be taken off each flange.

I had some good momentum going until I found out that I had ran out of FE timing cover gaskets, so I had to stop where I was.

If you look closely in the background, you'll see another cool little engine....a 465 inch Tunnel Port. It's a 12:1 solid roller engine....fun stuff.