My apologies for the delay in posting updates. Work and family life have taken up most of my time and I have found it difficult to work on the car. However, approx. 4 weeks ago I brought the Pace back home from my factory which is great as it's easy to head out into the garage to do some wrenching.

So, the latest updates are:

Assembled pedal box and drive by wire bell crank however couldn't fit the DBW and pedal box until I fit a new pedal box ceiling panel (being an early example, my car had a little over-exuberance in the lightning department where I ended up having nowhere to bolt one of the DBW bolts. Pace have since sent me the correct panel and it will be TIG welded in over the next week.

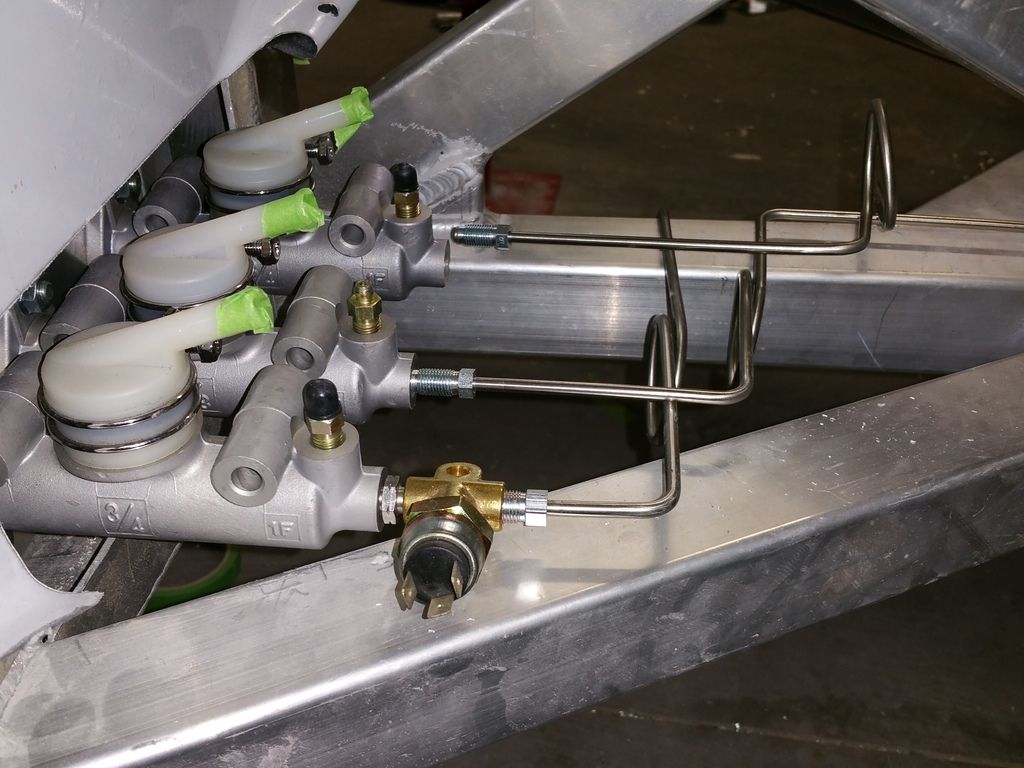

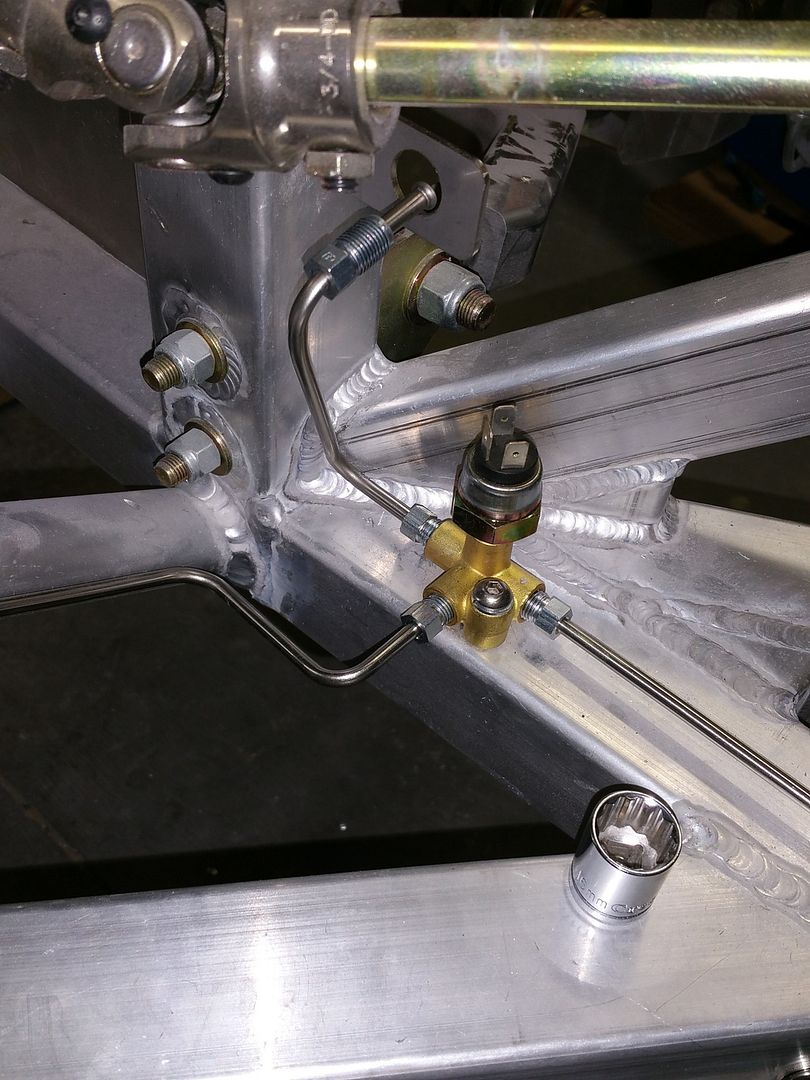

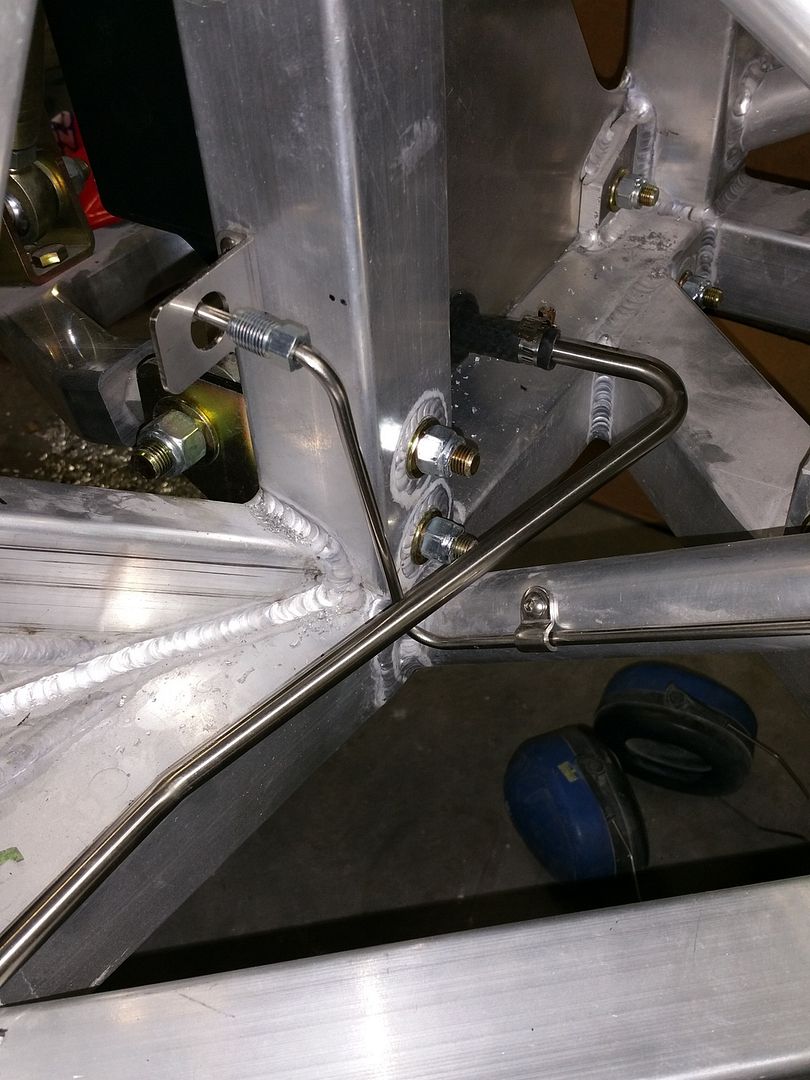

Installed all the hard brake lines, unions and pressure switches:

Installed the handbrake handle, cables and linkage:

Installed fuel hard line and vacuum line:

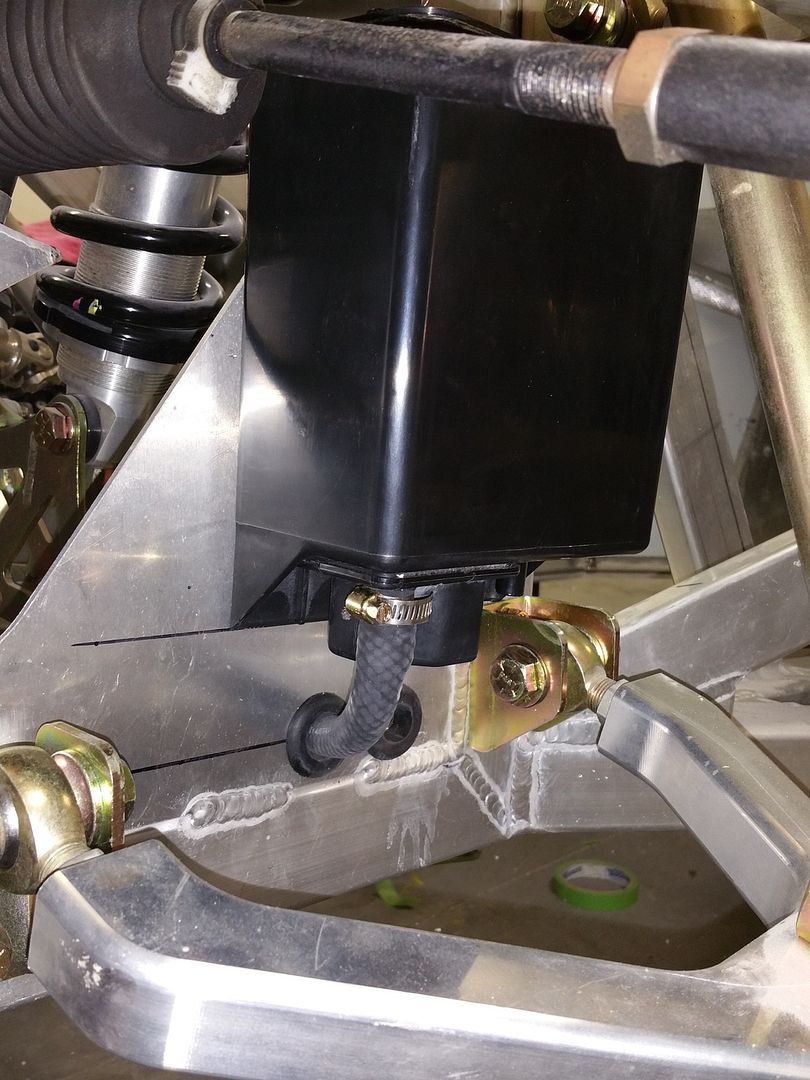

Installed charcoal cannister and fuel vapour vent hard line. The trick to fit the 10mm hose over the barb is to sand the barb right down to within an inch of it's life, chamfer the inside of the hose, heat the hose in boiling water, apply a little grease to the hose end and most importantly....push like a mother:

Installed clutch line stand-off:

Installed rear pushrod seals:

Fitted differential breather:

Guy, Russell and myself attempted to fit the LSA V8 and transmission a couple weekends ago but we ran into some issues with the clearance of the clutch feed line, plus it appears my engine mount holes were incorrectly drilled when my car was made. So they need to be TIG-weld plugged up and new holes drilled. Here's the motor/trans with the engine wiring harness fitted ready to be dropped in.

.

Well, there you have it. Progress has been made. Just have to keep at it one thing at a time....that's the key to success here!