I have been working on a McLaren M6GT replica and came up with a solution to a problem I have had for many years. The problem has been how to get a vacuum advance curve on a non-vacuum advance distributor.

The 289 and 427 Ford engines that were used in Cobras and Gt40s of the sixties did not have vacuum advance. The engineers at Ford did not think that race engines needed vacuum advance and deleted it. This lack of vacuum advance causes problems for engines when driven on the street.

1. Hurts fuel economy

2. Higher engine temperatures especially the exhaust system.

3. Hurts throttle response

One solution to the problem is MSD E-distributor. It works great, and does not have the “ugly vacuum advance can” on it. Problem is the E-distributors are not made for the 427 engine. Another issue is the timing is not very adjustable.

MSD also makes a couple of programmable spark boxes. The 6AL-2 Programmable, part number 6530 is designed to work on the street and is less expensive than the 7. The advance curve (actually it is really a retard curve, as the distributor is locked out at the highest timing point) is programmable with up to 32 discreet points along the RPM range. Another and key point of this box is the advance curve can be enhanced by using a MAP (Manifold Absolute Pressure) sensor. Hot Rodders running superchargers and turbochargers have been using the 6530 to retard the spark timing under boost, and running high advance under cruise. This has greatly helped their fuel mileage, engine temperatures and drivability.

BUT, what if you can’t get access to a vacuum source like on a Weber set up?

Take for example the McLaren M6GT I am working on. The engine is a 400 CID SBC. Aluminum block heads etc. with Weber 48 IDA Carbs. The engine was just not impressive at the low end. Even worse, due to the 3.22 ring and pinion gear and a 2.23 first gear ratio, and a 3 disc Tilton clutch, starting from stop was not fun, and starting on a uphill was almost impossible. The Weber carbs also created another problem. Where to get a vacuum source to run the MAP? We thought about drilling the manifold and tee-ing all of the lines together in a can, but it would look ugly, not to mention hurting the value of the manifold.

With EFI and IR (Individual Runner) or stack injection, MAP sensors do not work very well. The problem is the MAP sensors are too erratic with all of the pulses from the individual runners. Accumulator cans have been tried to smooth out the pulses, with some success, but I have not seen much success with bigger cams. Most people have found that alpha-N (alpha=throttle position, N=RPM) systems are much easier to tune on big lumpy race cams and IR manifolds. With this thought in mind I figured exchanging a TPS (Throttle Position Sensor) sensor for a MAP would be a viable alternative to controlling the spark timing with the MSD6530. While at SEMA I talked with a couple of MSD's techs about using a TPS instead of a MAP sensor. They told me “No it won’t work.” I explained to him alpha-N EFI systems, and that I wanted to try this with the MSD spark box. He gave me the look, like I was wasting his time…

So:

What I wanted:

1. Timing at about 5 degrees while the starter is engaged.

2. Timing at about 20 degrees at idle because of the camshaft overlap.

3. Timing at about 40 degrees under no load at idle.

4. Timing at full advance (all in) at 2,400 RPMs

5. 35 degrees total advance at full load i.e. WOT.

6. To slightly retard the timing at the RPM the torque peaks, to help prevent detonation.

7. Use the timing to help stabilize idle RPM, and help avoid engine stalling.

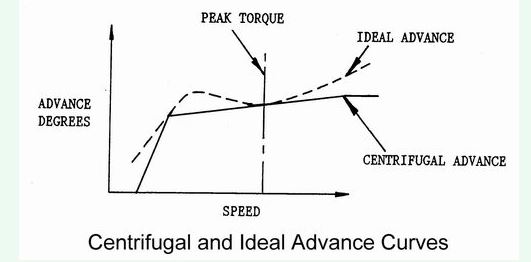

Basically I was trying to get a more theoretical optimum advance curve.

The limitations:

1. The MSD 6530 can only retard the spark a total of 30 degrees.

2. The running retard (RPM dependent) curve can only be retarded 25 degrees

3. The MAP signal can only retard spark

As you can see with the 30 degree limitation, there will have to be some compromises. For example 40 degrees idle spark timing – 5 degrees start timing gives a spread of 35 degrees. Actually it is worse, since I needed to set the base (or locked out) spark timing at 45 degrees. So 45 degrees -30 degrees = 15 degrees. So 15 degrees is the lowest spark timing I can have. This is a little bit more spark timing than I wanted, but ended up working out OK.

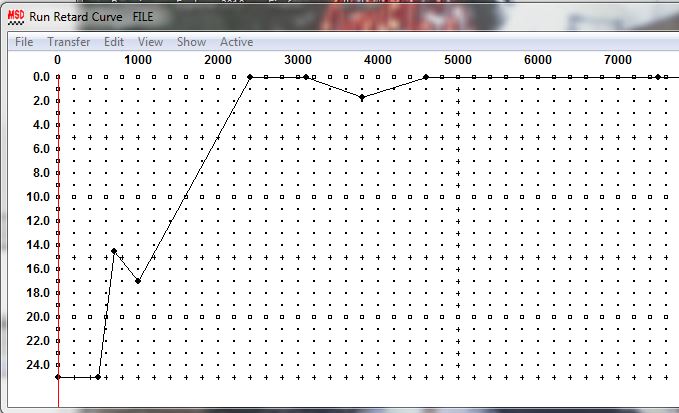

Here is the spark retard map based on RPM that I came up with:

It just so happens that the MAP sensor and TPS sensor connectors are interchangeable. Seems like the GM engineers where planning for this.

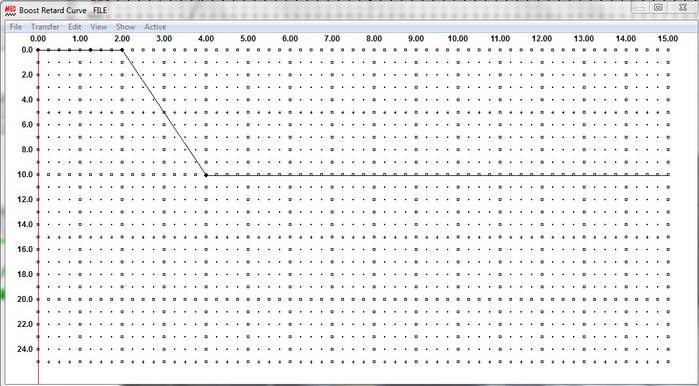

Here is the TPS vs spark retard map I came up with.

The TPS is labeled in pressure because the ECU thinks the TPS is a MAP sensor. The TPS at closed throttle reads 2 PSI. At quarter throttle the TPS sensor read 4 PSI. At closed throttle I wanted the ECU to not retard the timing at all. This would give me maximum ignition advance. This would also correlate to a high manifold vacuum. At quarter throttle I figured that the manifold vacuum would be nearly zero and so I set up this point where I would have maximum spark retard for the TPS. I am sure that a linear curve is not ideal, but it was quick. Remember the MSD technicians said this would not work… I got a start retard by hooking up the launch retard switch to activate during starter engagement to get the full 30 degrees of available timing retard.

The results:

The drivability was greatly improved. Starting on a hill is now a no drama affair. Throttle response and power are much, much better. So much so that it seemed to be a totally different engine. I have no data yet about fuel economy or exhaust temperatures. Maybe when the weather breaks...