Quote:

Originally Posted by tnewland

Dan, could you clarify "reverse" post batteries (the ones that Cobras require). In the case of group 24 batteries, is it the 24F that has reverse posts? At Gould IIRC it was either "Ford" style 24F or standard group 24. But confusing the issue at the time was the fact that some GM cars used "F" post batteries!

|

I’ll try. Understand my frame of reference is from mostly 1965-70 Mustangs (standard, Boss, and Shelby versions) and original CSX2201 and later Cobras. I am going to back up a few moments. Disclaimer, details are in regards to original CSX2201 and later roadster chassis.

In regard to the original post. “What battery was used in the 289fIA cars?” “289fIA cars” is going to mean different things to different people. Literally any Cobra from CSX2001 onward completed to conform to Fédération Internationale de l'Automobile (FIA) race sanctioning organization rules and race in their events was a “FIA car”. That is from back in 1962. In a more modern meaning most people think of the five (5) special competition “wide rear wing” (a.k.a. colloquially “cut back doors”) race chassis completed in 1964. The ‘cut back door’ cars were based on CSX2201 and later chassis. CSX2201 and later street roadster had different terminal post locations end to end relative to where the fill caps than Mustangs. Getting something new made that looks like some Mustang’s battery is easy. (CSX2001 through CSX2200 is a different subject as more than one wiring arrangement, design, and battery were used.) My original comments hinged on CSX2201 and later chassis, the same base chassis completed as cut back door racers. (The cut back door car chassis were street chassis that got modified before leaving AC and modified more by SA into finished racers.)

From an earlier post, "Posts orientation for street cars is opposite that of a Mustang" Ford car wise people hunt for original fitments for 1965-70 Mustangs more than anything else I know of. Over the decades quite a few people have posted batteries with positive and negative posts placed like 1965-70 Mustangs for sale to the original CSX2201 and later Cobra owners market not realizing original equipment positive battery cables weren’t sized length wise or installed location wise to go to a battery like a Mustang had. The negative cable could have its chassis mount location changed to reach.

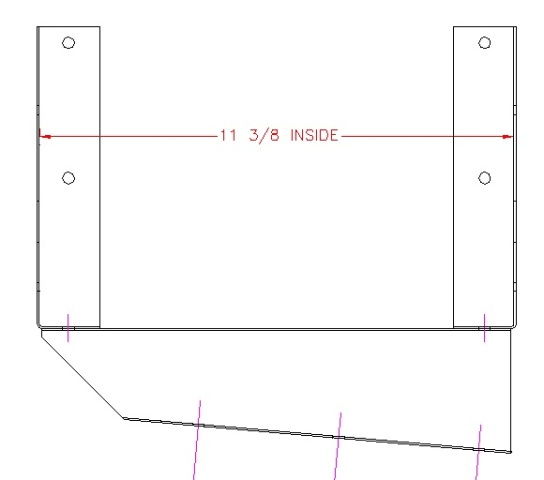

AC Cars Ltd supplied the battery mounting bracket and the piece of British specification marine plywood that fit inside the bottom (same plywood used as a gap filler between upper and middle fire wall panels at their overlap joint). The holder was nominally 11-3/8” wide inside side to side. Functional width was a little less because the Cobra unique J-bolts for the top channel clamp fit on the inside the holder’s side walls. Not shown in the sketch below is the deformation required for the hole in the side wall on the engine side that the holding clamp j-bolt on that side must hook into. As drawn it is for CSX2xxx chassis with battery ahead of the right side footbox. Deforming the hole opening is required because the battery heat shield assembly is attached to the engine side wall of the bracket. The deformation must be pronounced enough for the bolt hook to fit in.

Service Group 24 batteries Ford sold in 1985 (one for a Chevy application I believe) was easy to remove and install in our unrestored black car. The Ford BX-24 battery that replaced it years later was easy to install. The Ford BXT-24 model battery of 2004 was difficult to get in and years later back out as the case was physically wider and longer. The Ford BXT-24-A battery installed this year (2018) was again physically longer and wider than anything we had used before. To get it in we had to temporarily remove other components to allow the top rim (which now includes an even bigger integral handle) past without damaging the car or our fingers. We considered loosening the battery heat shield assembly as that would have helped but retightening the three fasteners would have been difficult. The Ford BXT-24-A model takes two people to deal with in an original car as originally built. What was quick and easy for one person decades ago has now become a couple of hours of effort. (Next time we will probably find something that physically fits our old beater easier; assuming I am still around in another dozen years ±.)

As I have only used Ford brand service batteries I cannot comment on any other brand. We have gotten as many as 14 years service out of each Ford battery (any car or light truck). Ford offers "24" sized batteries. To them everything they have sold over the counter for a particular application since they bought Auto-Lite® in 1962 is for them is probably just that, the same application. From memory the Motorcraft® 24 sized battery of 1985 was pretty much just a rectangular box with caps and terminals in the top. What they sell now has an enlarged top (mostly long wise) that includes a large integral plastic carrying handle. I cannot tell you what the based base foot print has been all these years, I would imagine that the bases have conformed to some industry standards and tolerances or another. If one had unobstructed straight up and down access any of the ones we have used would have been no problem to install or remove. That is not the case in a CSX2201 and later Cobra which not only has the battery under the right wing but under the cockpit ventilation hose on that side, the starter cable, positive battery cable, and the starting solenoid the cables attach to it over the battery. The horn relay is also over the battery but it is smaller, mounted higher up, and further from the engine. No matter what battery you have to negotiate around the right side scuttle hoop support and unless you remove it the battery heat shield can be in the way depending how you try to rotate the battery in. Passage by the heat shield is close in any event. CSX2201 and later cars also have a horn installed on the right side scuttle hoop support between the alternator and battery heat shield and it too can be in the way depending on battery dimensions and how two work the batteries in and out. In such close quarters adding in effect a flange around the top of Ford brand batteries made them harder to get in or out. We put a current Ford battery in our red car too. It also required disconnecting the wires from and removing the starter solenoid allow the battery to wiggle by.