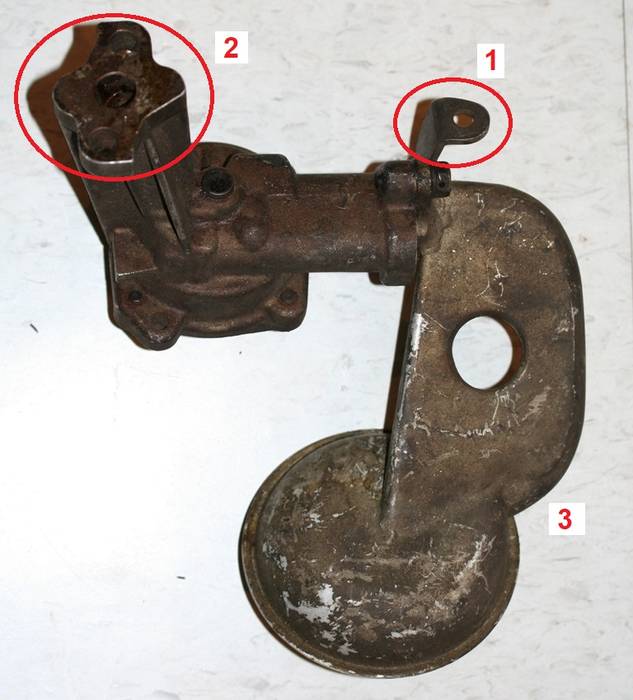

One of the most significant modifications to the short block assembly was the addition of support structures for the

oil pumps. The XHP-260 engines from Ford had this set of modifications and Shelby used them with very slight revisions from then on in small block engines.

Bracket marked 1: Added to tame vibration in the aluminum

oil pump so that the pump mounting based marked 2 would not fatigue and snap off. A doubled ended main bearing stud from another Ford heavy duty application doing a similar job was used at the main bearing cap. In 1963½ HP289 engines Shelby American reused the stock fasteners but added holes into their heads for safety wiring. Later they used aircraft drilled head fasteners.

Gusset marked 3: Added to tame the vibration in the

oil pump pickup. The modified part was cadmium plated. WARNING. 1962 pump pickups and 1963 onward parts are for different depth oil pans. Oil pans got shallower starting in 1963. If you put a 1963 or later Ford pan over a 1962 pickup there is little to no space for oil to get into the inlet and that is without somebody jacking the engine up by the pan and pressing it up some more. XHP-260 engines had 1962 length modified pickups. All the HP289 engines had 1963 onward length pickups.

The other significant oiling system change was the addition of a shim behind the internal relief spring of the stock pump to increase cold relief pressure. (These engines have little or no oil filtering until the oil warms and its viscosity goes down. On cold starts cold viscous oil does not pass through the element well. To prevent damage the bypass spring opens and lets oil go around the filter. Putting a shim behind the relief spring increases that cold start relief point.)

A set of correspondences between Shelby American and a customer surfaced that illustrates the issue of breaking the oil pump off its mount. A customer wanted to race his new Cobra but did not want to pay for having Shelby American race prepare the engine. The oil pump broke away and the customer was upset. The response he got back was a pleasant ‘we told you so’. Remember these were stock cast aluminum assembly line Ford pumps. I never heard of any trouble if a Melling® cast iron pump was used later on.