Quote:

Originally Posted by Gaz64

The number of clutch plates does not affect the feel at the pedal.

The pressure plate diaphragm spring, and then the throwout fork/hydraulic cylinder ratio, pedal ratio, determines the pedal effort.

Gary

|

What Gary said is spot on.

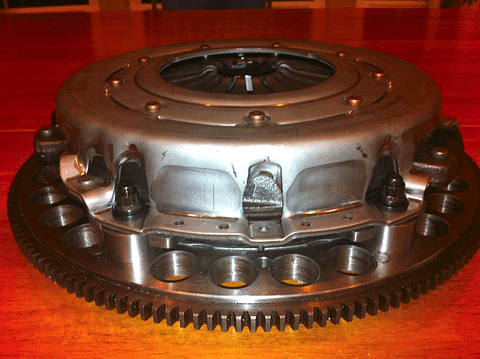

I made my own 10.5" dual disc clutch before McLeod had their RSX/RST versions commercially available. The clutch set up is particularly important if you want the car to drive properly and shift correctly. Here is a picture of my finished, assembled unit;

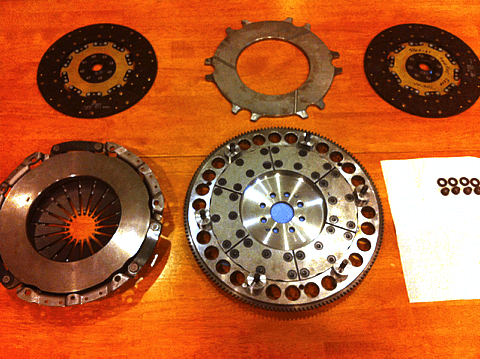

Here are pictures of the finished components, prior to assembly;

The pressure plate was a 10.5" Ford FRPP component that uses a high leverage diaphragm spring to provide a high clamping force at a low pedal pressure. Like Gary has already pointed out, you have complete control over how this feels by properly selecting the throwout fork/hydraulic cylinder ratio, pedal ratio. My pedal feels very light, very much like an OEM showroom stock vehicle's clutch.

The discs I used are organic McLeod solid hub discs for their older style dual disc clutches. McLeod uses a wavy spring called a Marcel spring between the friction material and the steel disc, friction material, mounting plate. The effect is a gradual compression of the wavy spring as the clutch applies until the friction material, marcel spring and disc substrate stack solid. The driving experience is a silky smooth engagement anyone can easily handle when driving it.

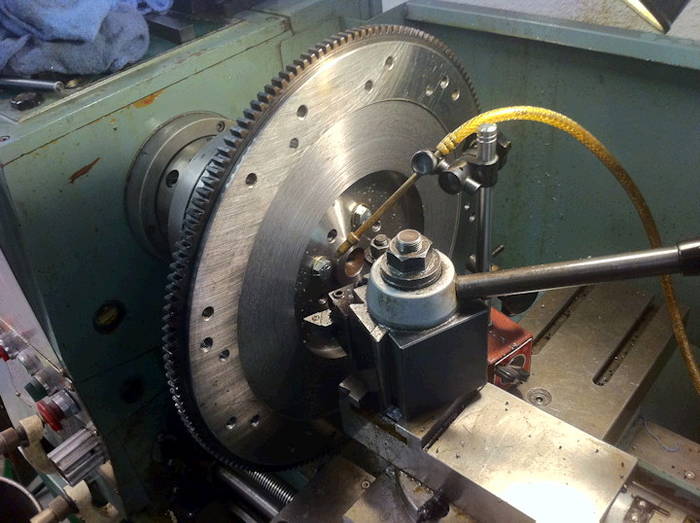

The floater was a Crower floater that I modified to work with the layout on my clutch build. The flywheel was a fabricated unit that I built to use replaceable Crower heat shields from their blown alcohol clutch designs. Here are a few pics of it as I cut the relief for the heat shields;

And then again later as I am drilling the holes around the circumference to remove rotating mass I did not want.

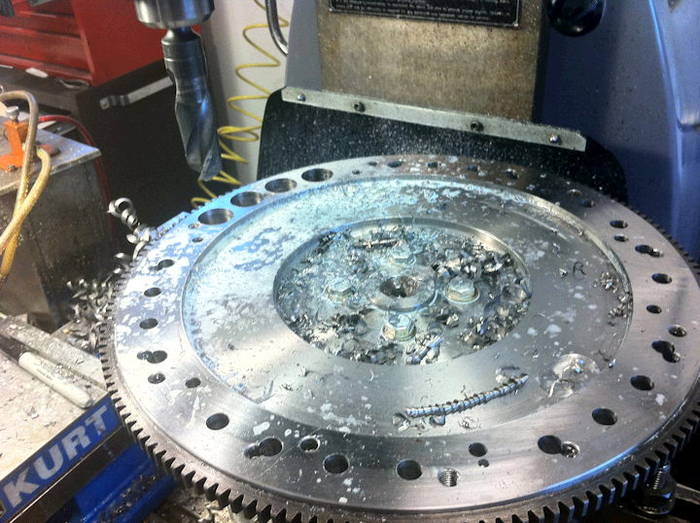

After the perimeter I go in to locate the attaching bolt holes for Crower's heat shields;

This is the finished wheel less the heat shields;

And of course this is what it looks like in final form with the heatshilds attached;

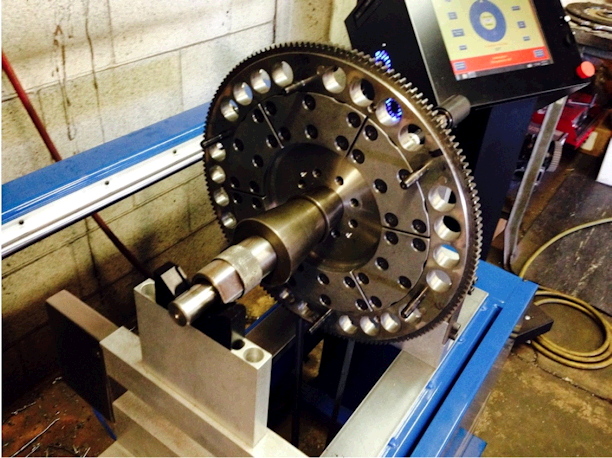

Once I had completed the flywheel, I took it over to the balancer to see how much imbalance I had added to the assembly.

I was surprised to find the wheel was within 1 gram of a perfect balance! Who said blind squirrels can't find acorns?

BTW the cost for the entire shebang was somewhere around $600 or $650 when I did it about 10 years ago.

Driving it, it has a light clutch pedal, smooth engagement and just an all around pleasant driving experience.

If you buy a performance equivalent and you do not pay attention to the clearance stack up in the clutch pack you will not have a happy experience. If you do and you do not screw up your clutch linkage you will be very pleasantly surprised at how light the clutch pedal feel is and how predictable the engagement is.

Ed