2008. Improving the WCC Cooling System

The biggest challenge with any car design that uses a high horsepower motor is to manage the heat rejection through air flow and coolant flow. Cobras are no different. So upon filling my cooling system for the first time I realized the WCC provided radiator leaked as fast as I filled it! What a POS ! That turned out to be a blessing in disguise. The WCC kit supplied radiator was from some stationary engine( generator?) and was a brass and copper design that no joke weighed about 40 pounds! This unit was never designed for automotive use, it had a 4 inch thick core. The radiator is the heart of the cooling system, its the foundation. So I called up a famous radiator company in South Carolina and had a custom aluminum radiator built to my specs to handle 500+ hp

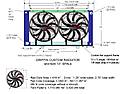

I chose to use twin SPAL 13 inch fans because they are an OEM fan supplier and durable. SPAL fans protect some of the most expensive OEM production engines in the world. They can be trusted. Each fan rated at 1,700 cfm. Other car builders I spoke to advised to always over design the fan size and flow rate. You can control the on /off temp strategy with a controller to optimize them later. I achieved 69% core coverage with these twin fans without a shroud fitted. With both fans running you can hold a sheet of 8.5x11 paper 5 inches away and it will suck it out of you hands. I have air flow!

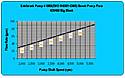

Dont forget about coolant flow!. You want to maximize the flow at idle for a street car so you can manage the heat in traffic. I ordered a WP pulley to ensure its as small as possible to ensure max coolant flow in the low rpm low air flow through rad modes like traffic. The Ford Racing crate motor used an Edelbrock high flow WP. Contacting Edelbrock they were happy to share the pump curve with me, their customer. I also changed the lower hose design such that the chrome expansion tank 5/8 line fills into the lower hose to reduce air pockets. The last mod was to add a coolant air bleed valve to the water outlet neck on the intake. Its a production GM part. Btw. I learned all these off shore made chrome water outlets are warped about .080” on the gasket surface and leak. I didnt have access to a mill to fix it then so I found an cast iron outlet from a 1969 429. Problem solved.

Here is my sketch and pics of it installed.