No matter which factory IRS you use, you will need to narrow it to fit the Cobra. You may or may not want to use the OEM uprights. If you do use them, make sure the upright you use provides enough room for a large supporting bearing ID. Some of the uprights (Ford calls them knuckles) leave the drive hub bearing register with a thin supporting wall that can crack in performance applications.

This is a pic of the current offering from Ford;

Not shown clearly in the picture is the backside of the wheel hub. The bearing surface that rides in the bearing anchored in the knuckle is quite thin. For daily drive usage not a big problem. For performance applications a high probable point of failure especially on the T-Bird generation of IRS designs,

The other thing you want to be sensitive to is the distance from the axle centerline to the front of the pinion. The newer Ford IRS centers have an extended pinion. Normally this would not be a problem. On our cars it aggravates another drivetrain issue — driveshaft angle.

With drive shafts that are typically 12 inches long and sometimes shorter, the car builders predisposition to use equal length half shafts produces a significant angular offset from the transmission tail shaft in the horizontal plane.

Depending on chassis design and space available you want to build your iRS with a centered pinion if at all possible. U-joints will last longer and the "V" component of an NVH measurement will drop dramatically. Translation: the car will drive with much less vibration and U-joints will last much longer.

A nice touch on the new generation IRS's from Ford is the use of CV joints instead of U-joints. Try to adapt as much of this as you can — again reduced NVH and improved driving experience.

A centered pinion means unequal length half shafts but this is not a problem, although it complicates the half shaft ordering process. That said most shops will work with you to get proper length half shafts made.

If your chassis style has the IRS center section tightly enclosed in a chassis construct that centers the IRS housing your pinion is automatically going to be offset towards the passenger side of the car. If you want to center the pinion in one of these chassis you will end up doing some re-design and re-engineering. Not impossible but more work.

The earlier T-Bird IRS center might be easier to hang in the car and they definitely will have a shorter pinion snout so driveshaft misalignment is further reduced. If you elect to use the earlier generation IRS center get the one out of an 2010 or so Elxplorer, it is a little more robust but has much larger mounts at the nose of the pinion, see below, The Explorer center is the one on the left.

The center section on the right is from an 03/04 SVT Cobra which, absent a few cosmetic differences, turns out to be indistinguishable from other aluminum 8.8 IRS housings Ford offers with the exception of the Explorer housing.

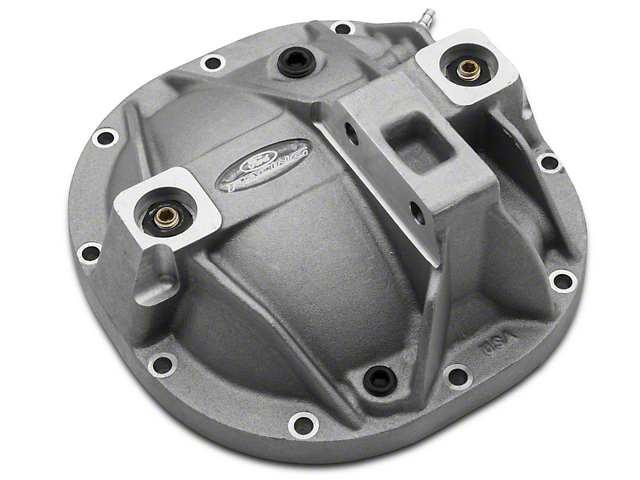

There is a very robust rear cover available from FRPP that will fit the housing to address the paper thin OEM cover breakage problem. This is what the FRPP rear cover looks like;

In the end you might find the T-Bird generation of IRS could a better fit for your build.

No matter which path you pursue you are going to find yourself in the custom half shaft swimming pool — there is no escape.

Ed