Also notice we made our adjuster nuts that fit inside the control arms so it is easy to adjust the control arm without taking the control arm off the vehicle. Just break loose the jam nut and turn the sleeve nut and tighted, Done. If you are making a straight camber adjustment you should adjust both the front and rear of the control arm the same amount to maintain the castor.

5. The caster we set at 5*degrees at the shop and don't want to change it, but it did cause us to have to install Power Steering because as we started getting bite on the track, the Front end was getting very hard to turn the steering wheel.

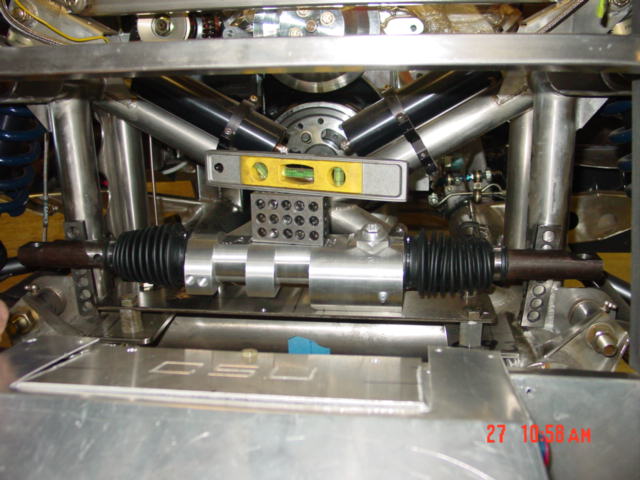

6. That was why we installed a Appleton power steering unit, because they are one of a few manufactures that can make a 23.25"inch long rack that we needed to make our bump steer work out right.

a. The other thing that most racers debate is Ackermann Theory. That means that the inside wheel of the turn is turning in more to help the outside wheel turn in to the corner. We like Ackermann and on GT-1 type of cars because they are so heavy and big as compared to Formula Cars, we have found out over the years that these type of cars like Ackermann. You really notice when pushing the car around the pits, it's very easy to push in a corner, as opposed to some cars that are very difficult to move if you turn the steering wheel. Sometimes it's the locked up rear end that makes it hard to push around the pits, but anything we can do to help the chassis get around a corner is a advantage.

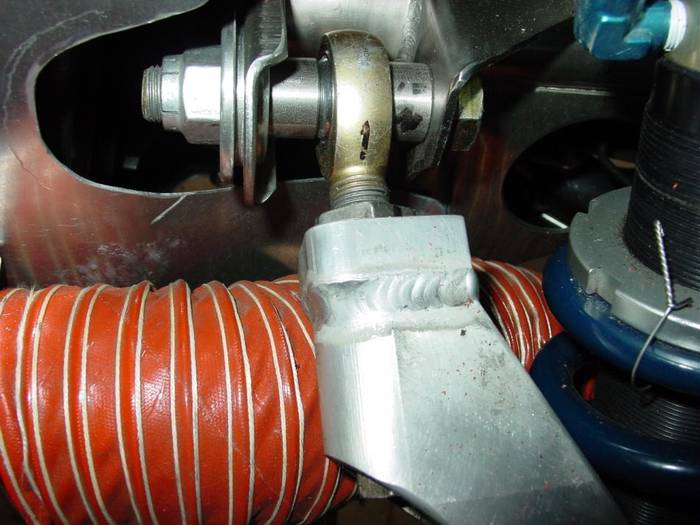

Here you see that we machined material off the back of the upper control arm to get more castor

Here you'll see we added material to the Front of the upper control arm to get the caster where we wanted it...

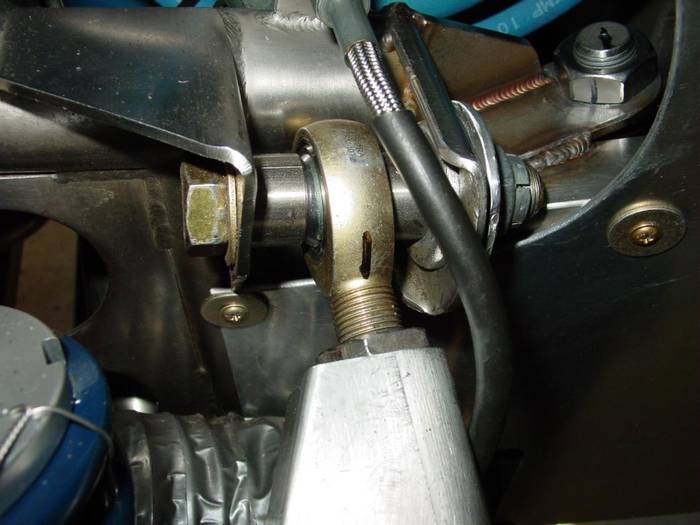

Here you see the nut adjuster on the lower control arm...also that the lower control arm is steel.

Here we show how we are achieving our Ackerman in the steering because the rack is further back then the steering arm giving the inside wheel a tighter radius then the outside wheel