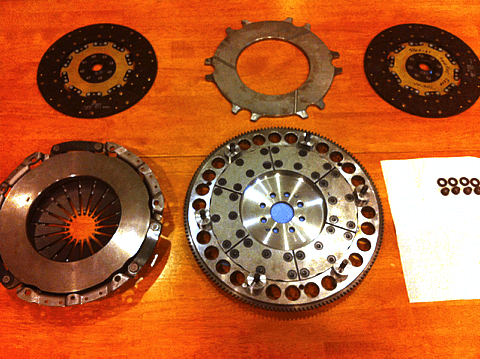

What you end up using is, in large part, driven by your power level and driving style. This is a picture of the clutch I use;

It is a "home brew' dual disc that I made from commercially available parts at the time. The pressure plate was an FRPP performance unit with a high-ratio diaphragm spring for a softer pedal. The discs were off-the-shelf McLeod 10.5-inch units they used in their (at the time) 'Street Twin' dual disc units. The flywheel was someone's (can't remember who anymore) billet steel wheel. The heat shields on the flywheel were Crower, and the clutch stand bolts were ARP rod bolts.

The flywheel looked like this after machining the perimeter lightning holes and the recess for the heat shields. I am locating their attaching fastener holes below.

Here is the finished flywheel ready for the Crower heat shields;

This is the finished flywheel before balancing;

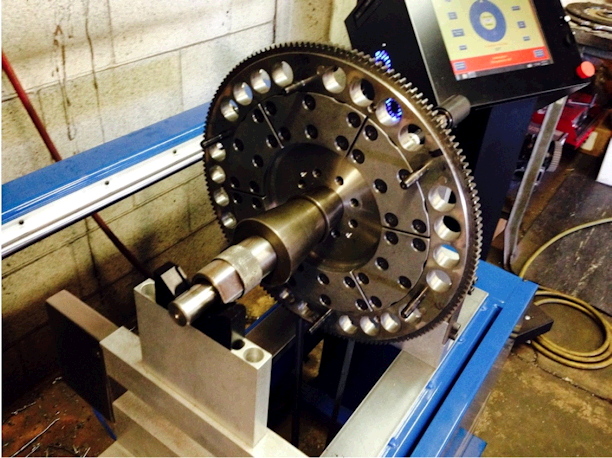

Here is the finished flywheel being checked and corrected for balance;

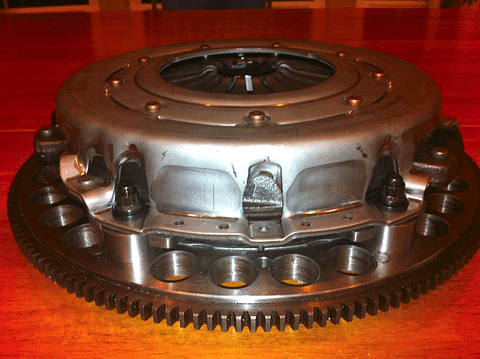

And this is the finished assembly before installation;

When you do it yourself, you have complete control over what the finished product will be/look like. So you can make it a custom fit to your personal desires.

This clutch was a 2800lb plate load organic disc unit with a torque capacity of well over 1,000 ft/lbs. I don't recall anymore but want to say it was something like 1,300 ft/lbs. It is an excellent daily driver because of the organic discs and soft pedal. For a track clutch, I would use a more robust lining.

I like the dual disc because of its torque capacity and also because of its soft pedal. That may not be your cup of tea. However, you can brew your cup any way you want when you brew it yourself.

BTW total cost for everything was about $600, as I recall, and that was about ten or twelve years ago. Your ability to do the same thing is only limited by your initiative, access to parts and machinery.

If you opt to buy, you will want to be in the 2400 to 2600 lb plate load window with twin discs and a high finger ratio pressure plate so your left leg does not complain about a stiff clutch.

McLeod (and others) make nice, smaller diameter, twin-disc versions today that will work with your existing flywheel. They are definitely worth a look.

PostScript:

The floater was an off-the-shelf 10.5 inch Crower unit, also.