Thanks!

The short answer is that is how AC made these boxes in the 60's.

All the bends in this box are as they were back then. The exception to the box is the bottom. The originals were a solid bottom that was part of the back panel.

The long answer is that I weighed the cost, originality, my capabilities and function. I can't comfortably cut or bend .074" steel this precisely right now.

The most common update I've seen to this box is making the bottom a removable panel for access to the pedals/mechanisms. Kirkham adds flanges to each side on the bottom and a cover, so that it's open and they only weld up the corners of the box.

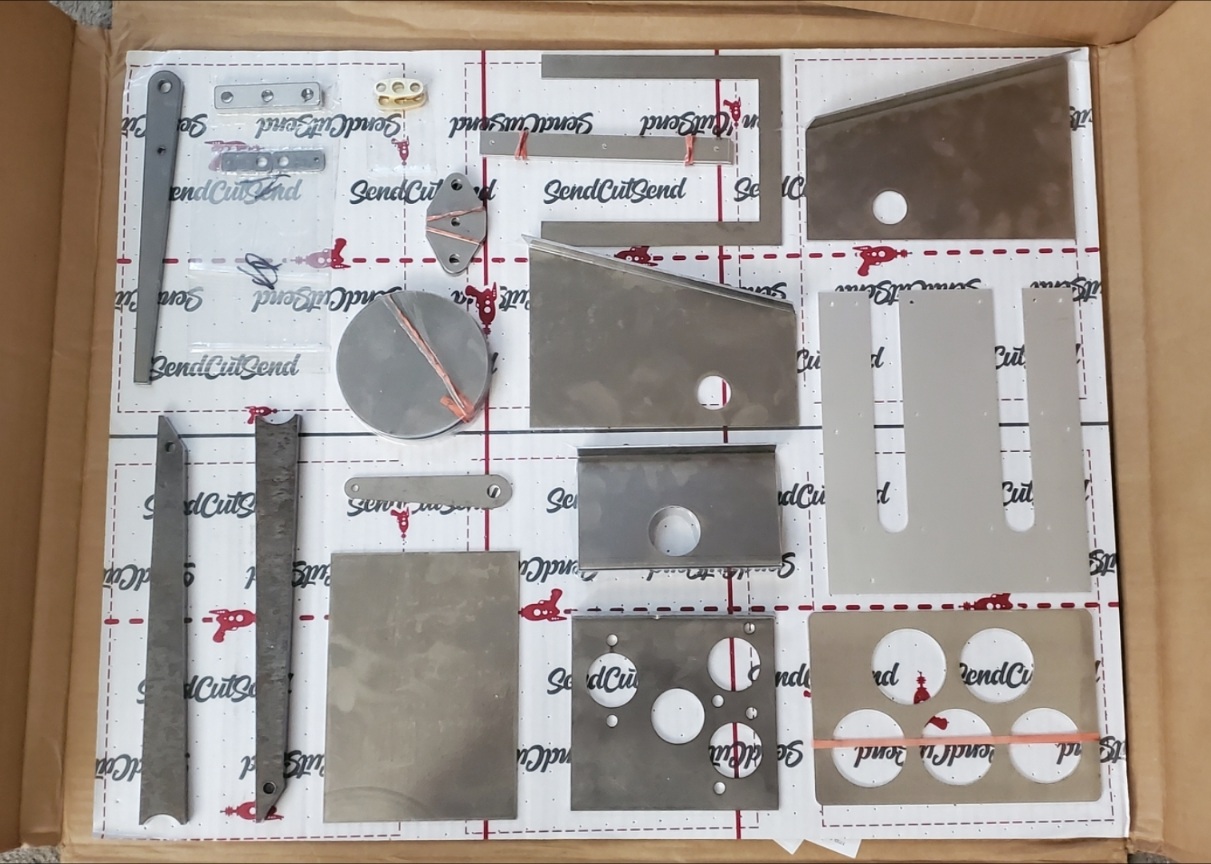

I opted for a weld in piece for the flanges. This thickness welds easy enough that it didn't seem to be a challenge. The front panel is thicker because it's essentially the bulkhead, so it wouldn't be part of the box anyway. I used Send Cut Send to cut and bend these pieces. I've never used then to bend and wasn't sure that the I could use their bend calculator right.

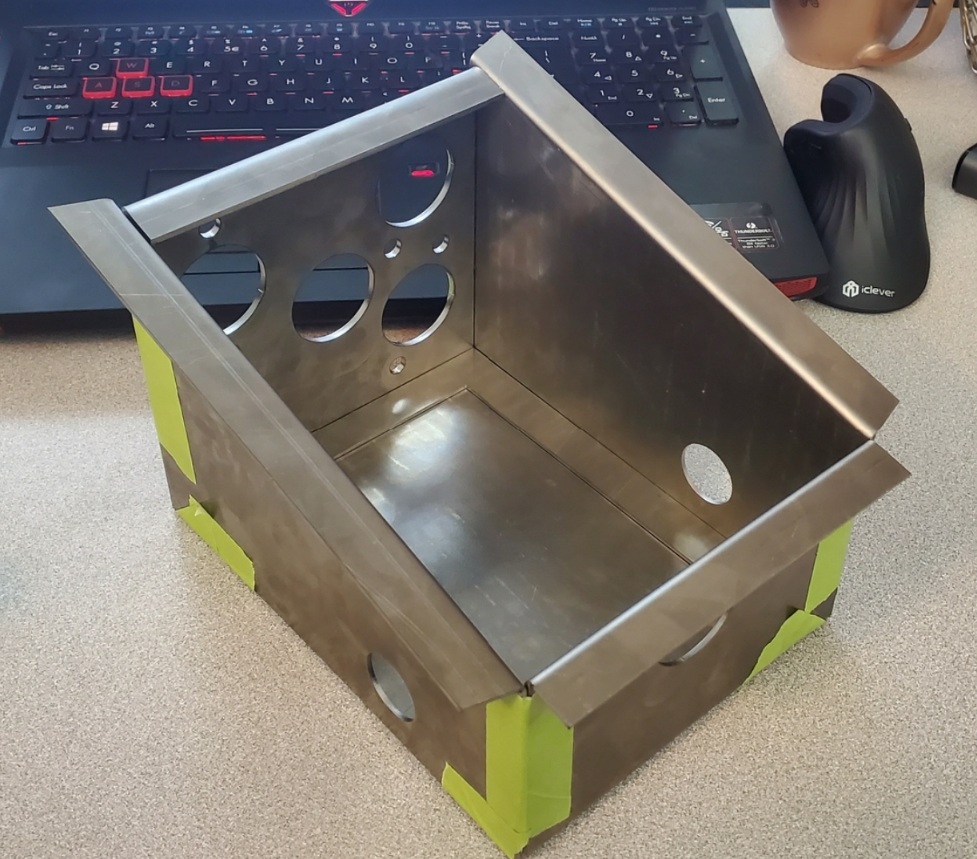

The box taped together for first test fit:

How I ordered the parts. Not all the holes are there. Some where made for placement so I could size them and others omitted so that I can place them myself after assembly.

The upside down look at the brake clevis guide:

Clevis pins without cotter pin holes. The two on the left are done, the two on the right need faced.

The clevises, pins and bell nuts:

The pedal arms were notched to bend then welded with a 1 inch offset.

.