Quote:

Originally Posted by eschaider

I was curious about how you made those springs, Shawn. Now I understand. Very crafty!

Was the music wire difficult to work with or pretty straightforward?

|

Bending it (this .055" music wire) was straight forward once I learned some of the rules. This is a torsion spring. Techniques vary with compression and extension springs.

-be careful with the removing the wire from the roll. It wants to unwind.

-cut off disc is a must to cut and deburr ends. No cutter will do well for long.

-deburr ends first. They will shank you.

-bending it is just overbending until it relaxes where you want it.

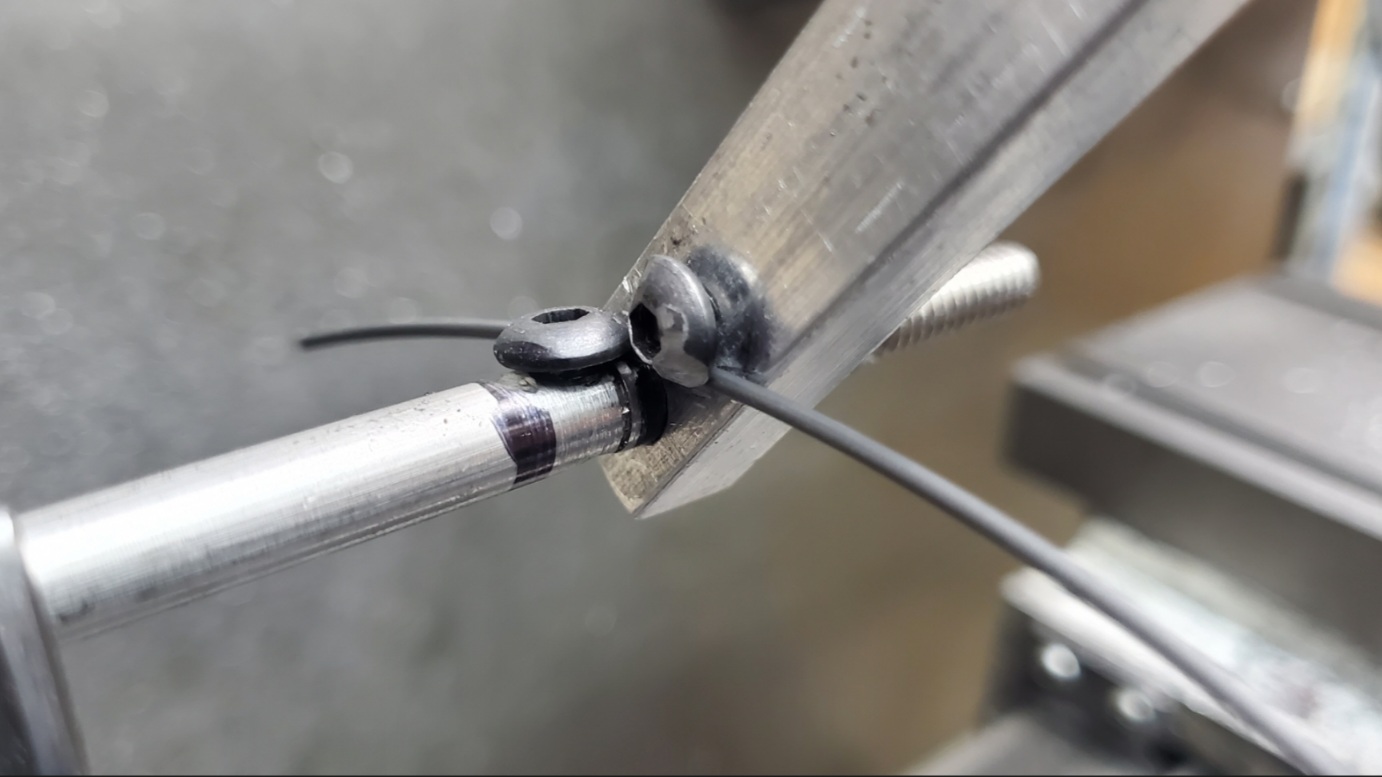

-bending tools need to clear the hold down screws if you want a tight winding. Both my hold down screws where trimmed considerably.

-the mandrel needs to be the same size or slightly larger than the pin.

-no lathe is needed. A bench vice would work for this spring just fine.

-keep the tension when winding.

-accuracy increased with practice.

-some straightening will help with precision too. The wire doesn't need to be laser straight.

-solid pliers will bend 90* well.

I started on a 1/4" mandrel just to play and used Vice Grips to hold it to the rod. Then I went to a slightly larger mandrel and got a 5/16 id on the coil. This was too small. The windings collapse when the spring is used and I couldn't get the pin through it. Using a 5/16" mandrel allowed the spring to relax larger and works great on a 5/16" pin. I made about a dozen springs before I got a pair I liked.

EDIT:

This Old Tony did a relevant video that shows almost exactly how I made the pedal springs. I used a hand turner.

Jump to:

https://youtu.be/jAawhg6JtyY?t=440

Whole video:

https://www.youtube.com/watch?v=jAawhg6JtyY

This is before I REALLY hacked up the screw heads. This is similar to some commercial spring tools.

.