+1 on what Brian (cycleguy55) said!

You are suffering from internet fictional information overload, David. There is nothing wrong with your engine. It will perform well for you for a long time with normal care. The

oil pressure will do no damage to the engine.

The one tender area that Bob identified, the potential for a distributer drive gear roll pin failure, is real and should not be ignored. If a roll pin has been used, it should be replaced with a traditional dowel pin. The dowel pin strength is vastly superior to the roll pin.

There are differing types of roll pins with differing strengths. This is a pic of a simple slotted tubular roll pin;

It is on the low end of the strength scale and the easiest of all the choices to fail. This pin in a 5/32 diameter (0.156") has a breaking strength of just over 2000 lbs. Its durability can be somewhat improved by using spring steel. The underlying problem is insufficient metal to provide strength. It should not be used in moderate to high torque applications.

The next step up the ladder is the rolled roll pin, no pun intended. This pin is essentially a spiral version of the slotted design. It looks like this;

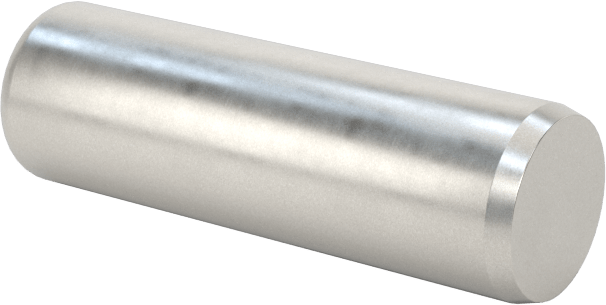

The rolled steel roll pin in the same 5/32" diameter has a breaking strength of 2200 lbs. Not a shrinking violet but there is better available. If you get the hardened steel versions, this pin will have a breaking strength of 2700 lbs. It's better, but there is still one more alternative. This is what it looks like:

A solid steel dowel pin, in a 5/32 diameter, has a breaking strength of 4100 lbs. It is highly improbable that you could damage that pin when using it to anchor the drive gear on the distributor. Of course, you could go up 1/32" to a 3/16" diameter pin. The breaking strength jumps by almost 50% to 5,900 lbs. This one fits into the virtually unbreakable category for your type of service.

The chances are 50/50 that Ford used a solid steel pin. It is more likely they used a rolled roll pin. Easy peasy, lemon squeezey, as the saying goes. Simply push out the old, push in the new, and don't worry, be happy.

Your

oil pressure is not out of line. Could it be lower? Absolutely! Switch to a softer pressure relief spring? That is the

oil pressure equivalent of discovering your car can smoke the tires with very little encouragement from the driver's right foot.

To fix the tire smoking problem, you have three choices;

- Put on sticky racing tires,

- Learn how to leave without smoking the tires,

- Disconnect two plug wires to kill off some power,

The one we all know is wrong is disconnecting two spark plug wires. In your case, you don't need to put the equivalent of sticky racing tires on the car or even learn how to leave w/o smoking the tires. All you have to do is put in a solid dowel pin (to ease your fears), drive your car and enjoy it!