Hello all.

Happy New Year!

Merry Christmas too,

if I did not mention it before.

All is well here in the semi-frozen north, and it time for another update.

I am still working on the roadster when I can, but things just seem to be a bit more stressed as of late, long day at work then when I do get home and things squared away, it seems my ambition to wander out to the shop has already wandered off somewhere else, weekends seem to get filled up with other things as well but when the stars do align things are happening

This time around I wanted to mention my radiator, suffice to say I did a lot of looking around, I know the early cars had a 62 Corvette rad and tank so that was one option, there is also a nice reproduction of the later McCord rad available from CSX parts but me being me I looked for the harder option

I read somewhere the Corvette rad is about 17 x 22 inches, I could not find a size on the later rads but knew they were made to fit in the same hole. I did not really want to go with a Corvette rad as I want to use the cast heater switch elbow and the vette rad has a very unique angled lower outlet that I felt would not line up very well.

I did consider modifying one but was not sure how it would go. In my looking around for another suitable donor hoping for something old school with brass tanks I could modify, I discovered a company called Northern Radiator, they sell blank aluminum radiator kits.

I am not the best aluminum welder but I can do it so I ordered what was listed as a 22 x 16 inch rad kit. I went through one of their distributors here in Canada called Truck Parts superstore ( no problems to deal with) and received the pre welded and pressure tested basic radiator unit plus inlet and outlet fittings, filler neck and drain fitting, all for about $300 Canadian dollars.

I also ordered an extra 1 ¾ elbow for the lower outlet.

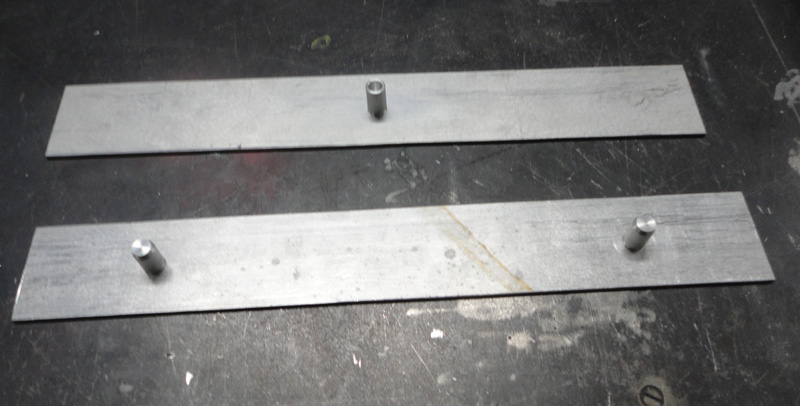

I made up the upper and lower mounts from 1/8th aluminum and turned the “pins” from aluminum rod , I made the upper one appear to be hollow to match the pictures I could find.

I attached ( tig welded) them to the upper and lower core supports and tried the fit.

I needed to adjust the upper mount a bit as I am sure this rad is a slight bit shorter but I don’t think it is to noticeable. I slipped in the lower cast elbow that holds the fan switch and started figuring out the angles.

Turns out I needed to modify the elbow I ordered as it could be smaller and less than 90 degrees.

Then I checked the angle and added the upper hose tube.

Also , with much fussing and test fitting sorted out the lower hose tube to align as best as I can to the cast elbow.

After everything was welded up I plugged the holes and pressure tested the assembly and happily there were no leaks that I could find.

I think the radiator is done for now, However I might change the air bleed from the top of the tank now as I have since changed my mind about a rear mounted puller fan.

From a previous parts order I had the water pump to expansion tank tube, it was not what I wanted as I intend to run a heater so while the welder was set up I decided to try and change that.

I made a tube with a rib and welded it to the existing part and drilled the hole through on the inside, problem solved….. I hope.

I also made a repair to the expansion tank I acquired, the upper bleed hose tube was missing and when I pressure tested it the swaged lower tube was leaking too, so now it’s welded to the tank. But seems I did not take any pictures.

Then while I still had the welder set up I wanted to fix my intake manifold. It’s the classic Edelbrock F4B, apparently a copy or version of the Shelby or Ford label ones.

I picked this up a couple of years ago, a “barn find” I guess, it was used and dirty but in fairly solid shape. There was one odd thing however.

On either side of the plenum there is about a 3/16th hole drilled at a slight downward angle clean through making a fairly large vacuum leak. My best guess is somebody had some sort of cheater nitrous system or was planning on a system.

So I quickly cleaned up the spots and made a couple of plug welds.

I linished the area and then gave the whole manifold a sandblast to blend it all in, looks pretty good in the end so I gave the whole thing a satin clear coat and moved on to something else.

So that’s it for now, work continues and I will post again soon my friends.

However if I could ask anyone who might know……

What is the approximate center to center measurement of the soft top bow ferrules? I am talking about across the cockpit, is it about 48 inches? More, less ?

I am currently working on the cockpit area tubing and need a good reference to compare to my body shape. I know things are wonky there and I am trying to correct it as best as I can.

Thanks folks!

Stay warm,

Hudson

.