What Jim said about twins is particularly true when you use the more aggressive competition-style friction materials on the discs. A street-driven car's typical organic friction materials will work very nicely for you. The twin will provide a reduced pedal effort. On the 8 or 9-inch versions available from various manufacturers, you will have a very light pedal, even lighter than an OEM daily driver-style unit.

McLeod has two different families of twins. One is the RST/RXT family, and the other is what they call their Original Street Twin. Here are links to each one:

RST/RXT =>

Click Here

Original Street Twin =>

Click Here

The RST/RXT versions were developed for the modern-day blown stuff like the Hellcats and supercharged Coyotes and Camaros. The smaller diameter 8 and 9-inch diameter discs make shifting at high engine speeds easier than the larger 10.5" diameter discs used with their Original Street Twins.

In terms of power handling capability, they will all easily exceed 800 hp, which really isn't the issue. Torque capacity is the real issue.

If you use McLeod's HP ratings and assume they are measured at 7000 rpm, then the RST/RXT clutches with their 800 to 2000 HP ratings would be good for engines with 600 to 1500 ft/lbs of torque. McLeod rates those Original Street Twins with their 10.5-inch diameter discs for 1200 ft/lbs of torque.

At first glance, the smaller diameter clutch might seem like the way to go. In fact, it might be, but then again, it might not. The 800 HP version is the organic facing version of the clutch, which is only rated at 600 ft/lbs of TQ! Other than the nice light pedal, this is not significantly better than the clutch you are replacing — and will not likely last any longer.

The McLeod Original Street Twin uses a 10.5-inch diameter disc, and McLeod rates the clutch at a 1200 ft/lbs of TQ transfer capability, this comes with a lighter pedal than you currently have, but not as light as the smaller McLeod RST/RXT clutches. This clutch in one of our cars will substantially outlast your current clutch and McLeod's smaller diameter RST clutch while giving silky smooth engagements in day-to-day operation.

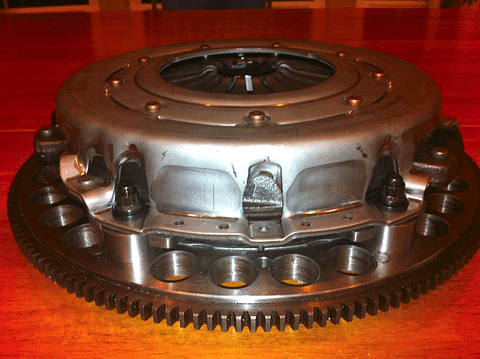

Here is a picture of my own homebrewed 10.5-inch dual disc unit;

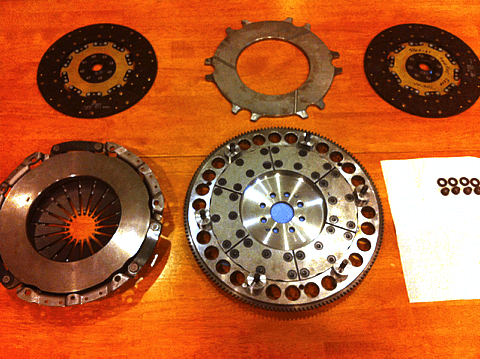

This is what the components looked like before assembly;

I used a Ford high ratio, low pedal force 10.5 inch pressure plate with about 2400 lbs of plate load. The discs are McLeod from their Original Street Twin, the floater and heat shields are Crower from their blown alcohol Pedal Glides, and the flywheel is my own, modeled after a combination of aftermarket flywheels, taking the attributes I liked from each and discarding those I didn't like. Predictably, I made a few mistakes in the fab process, but none were show-stoppers.

Two considerations worth mentioning are if you use a drive stand instead of a strap drive for the floater, then when you are stopped, you might hear the ringing of the floater as it bounces back and forth between the drive stands with the clutch disengaged. If you have side pipes, this is virtually impossible to hear! Unlike drive straps, drive stands can not be bent during engine deceleration.

I chose the do-it-yourself path partly because I could and partly because the total cost of the finished clutch and billet steel flywheel was just under $600. If you do not have access to a lathe and a mill, it would be challenging to build the clutch. If you pay someone to do the machine work, buying a ready-made McLeod (or another firm's) twin disc unit would be more cost-effective.

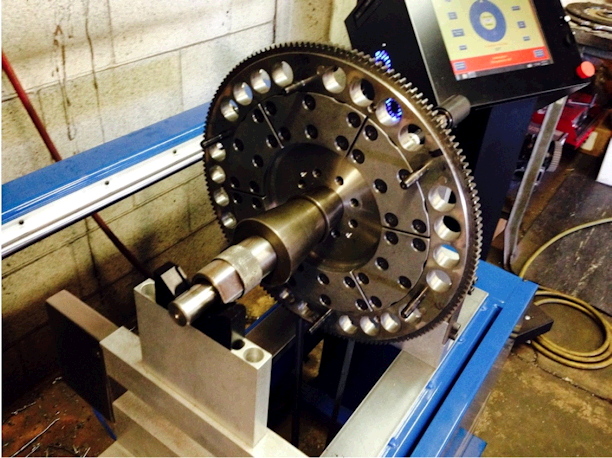

When I was all done, I balanced it, and to no surprise, it was spot on, well within less than a gram.

I have right at 600 ft/lbs of TQ from below 1500 rpm out to almost 7000 rpm; however, that is primarily attributable to the blower and the EFI tune. The dual disc clutch design and velvety smooth engagement is an absolute breath of fresh air compared to the heavy pedal, short life, single disc clutch alternatives.

The McLeod discs I use do not have a sprung hub. McLeod does use what is called a Marcel spring between the friction material and the disc drive plate. A Marcel Spring is a flat wavy plate-style spring that fits between the disc’s friction material and the drive plate. When the pressure plate applies it’s clamping force to the clutch pack, the Marcel Spring slowly flattens out, creating a spring-like tension that provides for that initial controlled slippage necessary for a smooth engagement. The Marcel spring, along with organic facings, provide for a very smooth engagement.

When you pick your discs, you can also use sprung hubs if you have enough stack height available in your clutch can for the throwout bearing to fit and operate. Depending on the depth of your clutch can, you may or may not need to trim the candlestick support for the input shaft to clear the topmost disc. Be sure to check your clearance there.

Postscript

The tougher and more aggressive non-organic disc-facing materials in time will all cause the clutch to chatter on normal acceleration from a dead stop. For a street driven car you want organic facings.