I've got a method through trial and error that works pretty well for me, first I mount the hose in a soft jaws vice...

at which point I snug up a cable tie around it, not tight, just snug....

at this point I use a diamond cutoff wheel that is mounted on my Dremel and begin to cut the surrounding wrappping using the cable tie as a guide.

The cable tie keeps the braided wrappping tight against the outer hose while giving a nice flat even cut without any stray "fraying".

I then

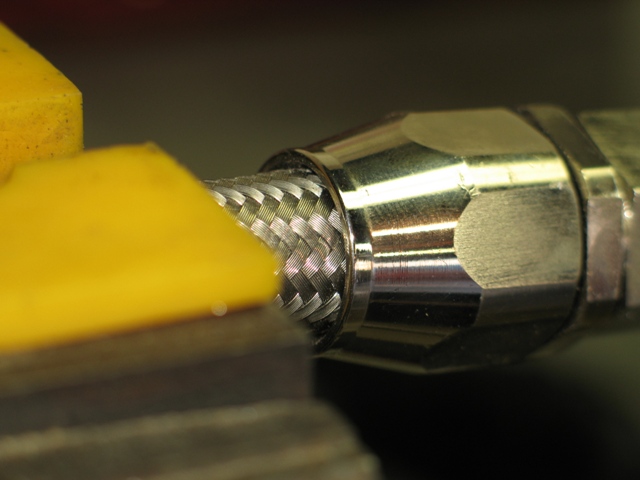

oil the braiding/hose and begin to slip the collar of the fitting on to the hose, the cable tie will slip back along the hose as the collar pushes against it keeping any strands from popping up...

once I have filled lthe collar end with hose I then screw the oiled down tube into the hose with taped jaws of a crescent wrench until it reaches the position Morris showed in his shots...

Once completed I blow the finished hose out with compressed air and then run a soft cleaning brush from my gun cleaning kit down through the entire setup, there are a bunch of good techniques in this thread, this is yet another way to do it.