I had one side where the door was "inset" and one side where it was "outset." Imagine that. I used fiberglass to build up either the inside of the door or the outside of the door. Use epoxy resin. I also went inside the door skins and reinforced the bottom of the door where the two pieces come together to make sure that I didn't loose structural strength and had a competent joint. You will need to sand through the gel coat to allow bonding and blending of the any new fiberglass cloth with the existing door. The following pictures should help.

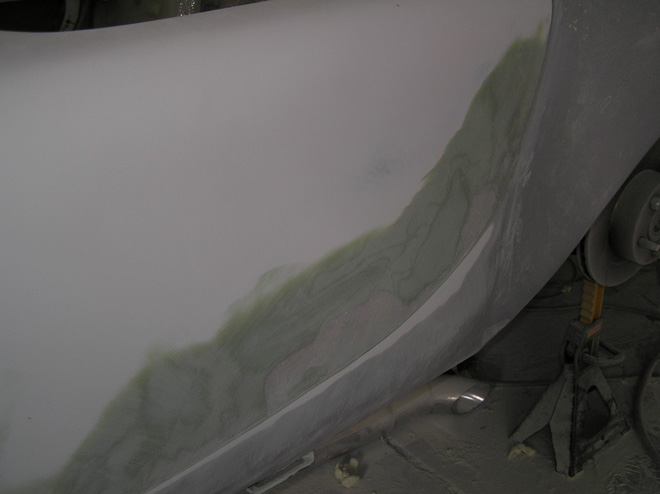

For the outside build up, I used mat to build the thickness and cloth for the last two layers.

I used regular masking tape to protect the body as I blended in the new materials;

Trim to fit and rough sand:

Several applications of body filler will create a new surface blended with the existing body.

If you've had to sand down the exterior and need to build up the inside, I just added glass to the inside:

The finished doors looked great:

Let me know if I can help some.

Rob