I've done one efi project already. Took a few years. Best years ever. Hunting, discussing, gathering and putting together a system is almost better than driving the end result.

I missed the process, the hunt, so I'm working on my next efi project:

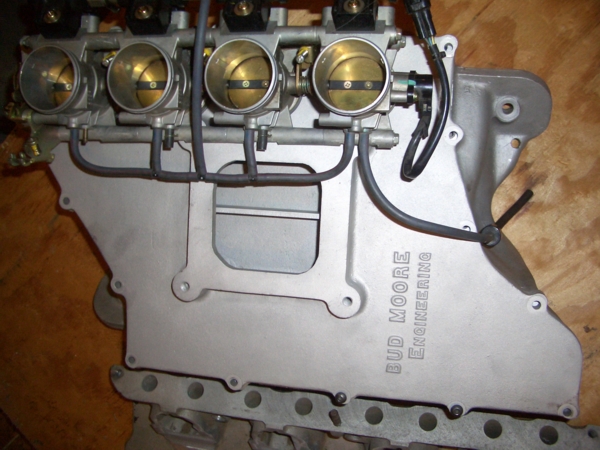

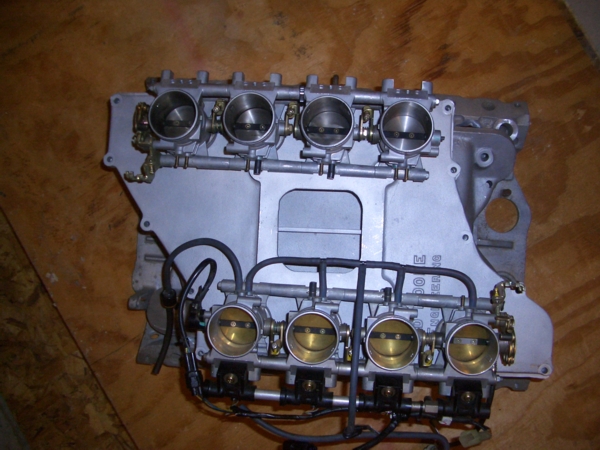

Basically a Bud Moore 351C crossram to be mounted in an FE Algon adapter...

Using a Mallory TFI distributor with Ford EPEC programable EEC-IV computer...

Needed a TFI distributor...Mallory to the rescue...

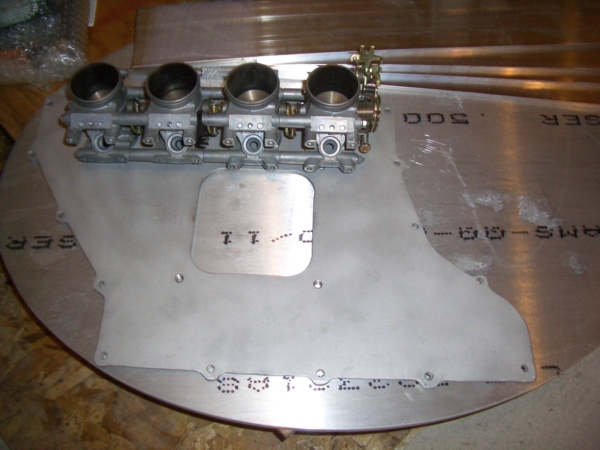

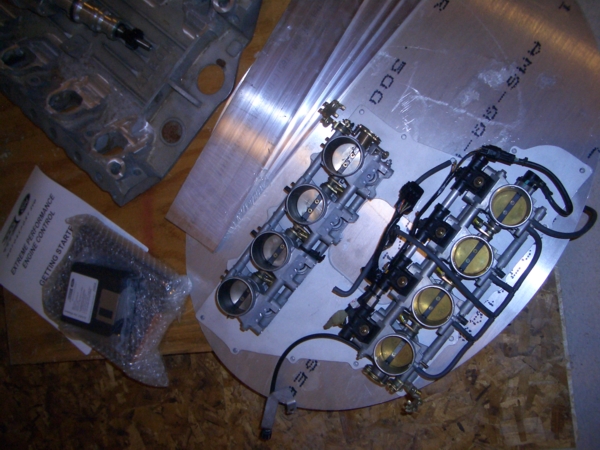

Spare top for the BM crossram will serve as a template for a new top to mount the 2 hayabusa sets of throttle bodies (46mm each)...

The hayabusa throttle bodies come with injectors (will mill for automotive-type), fuel rails, TPS and vacuum hoses (probably lose those). Sized like they were designed for this application. Did I mention they're cheap?

Project almost looks ready to put together. Sorta bummed. Sorta like the building/hunting/gathering part of projects best.

At least I won't see the setup under every hood

Anyway, that's how I'm doing efi, this time. I'd like to hear more about this 'self-tuning' system. I can still change ECM's if something better actually comes around. But I've worked with so-called 'self-tuning', and, at least the ones I used, weren't. You still had to get the curves and tables close, and then the software optimized things for you. But I'm willing to learn new things, be told I'm full of it. So I'll wait for the actual facts and install. I'll slow down my project until I hear more.

The total cost so far is less than $1,000 (lots of swap meets and talking with people). Figure on another $1,000 for final machining, and miscellaneous parts (though I think I already have everything? I have a couple IAC's, box o' sensors, injectors...). I've talked with Troy Trepanier about making me a custom aircleaner/mass air meter mount, and even with that, I think the whole project will come in under $2,500.

what it would look like assembled (ignore the big hole in the center

)...

Here you can see how an 87mm mass air meter fits nicely between the hayabusa throttle bodies. Their compactness really works, and did I mention they're cheap?

This shows how a standard FE 2x4 (or 3x2) aircleaner relates to this setup. Shorten it, widen it a little, and build in a mount to hold the mass air meter and it wouldn't look out of place. The only issue might be running throttle linkage across the intake. Thoughts on that include welding in tubing across the intake ducting (ala` Tunnelport

).

I'm liking this project because it'll put all the injection stuff on a plate, a plate that can easily be swapped for a carb plate if wanted/needed.

The only real question mark I'm still working on is whether to leave the injectors mounted in the throttle bodies or to try to weld in bungs to the Algon adapter or the Bud Moore base itself if the angles don't work (which will mean new fuel rails too).

So, another option you have, besides handing a box and a credit card to your installer, is to roll your own. Personally, I like a challenge.