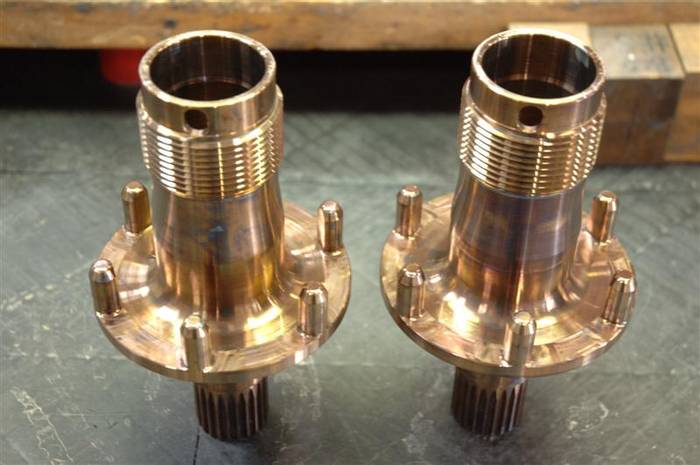

Just for comparison, here is our latest set of rear hubs. Our front hubs are very similar. Notice the drive pins are milled directly into the hub. This is done for MAXIMUM strength, MINIMUM part count, and minimum weight. By milling the drive pins directly into the hubs, we are able to make the entire part much lighter. Also, there is NEVER the question of "Did you tighten the drive pins????"

These drive pins will NEVER come loose!

The milling operation to make the drive pins is extremely difficult. At first Sandwich told me it wasn't even possible. I "persuaded" him there was enough room and he moaned and groaned, but got it done. I knew it could be done...there was at least 10 microns of tool clearance! What was all that complaining about anyway?

There is a very long reach that has to be done with the end mill to get around the snout of the hub and preventing chatter and tool destruction is a major challenge. This milling operation eats end mills like Rosie eats candy. But it makes the strongest, lightest, most corrosion resistant part possible.

Anyway, milled in drive pins is the LATEST and GREATEST mod on F1 cars which was only started this year. I like not having to keep track of so many parts, nuts, and drive pins falling all over the place and rolling under the bench.