Quote:

Originally Posted by FUNFER2

Talk to me about your aluminum 482 build, rotating assembly, cam type & numbers, heads, intake, carb. dyno numbers, durability, cost and how well you like it, or not. And even changes that you would do different, if you could. Photo's also. Give me all the poop ya have.

Thank you,

Kevin |

Kevin,

Keith Craft did a Fuel Injected 482 ci for me. Here's a summary of the specs:

- Shelby Aluminum Side-oil block, CNC ported aluminum, 4.250" Bore

- Forged Scat Crankshaft, 4.250" Stroke, Internally Balanced

- Forged Scat H-Beam Rods

- Forged Custom Diamond Pistons, 10.5:1 Final Compression Ratio

- CNC Stage II Ported Edelbrock aluminum heads with 2.19"/1.75 stainless steel valves

- TWM Induction Stack Fuel Injection Intake Manifold and 58 mm Throttle Bodies; modified for IAC motor with plumbing under intake

- Bosch 42 lb/hr Fuel Injectors running at 50 PSI and 47.5 lb/hr maximum output

- Competition Cams Custom Grind Hydraulic Roller Camshaft and Crane Hydraulic Roller Lifters (see below for CAM Specs)

- T&D Machine Products Shaft Mounted Roller Rockers

- Melling High Volume Oil Pump

- Aviad Cobra Oil Pan

- Ford Remote Oil Filter Setup

- BHJ Damper

- FAST XFI Computer with Electronic Traction Control

- FAST Dual Sync EFI Distributor

- MSD Digital-6 Ignition Box with Blaster HVC Coil

- Shelby Polished Valve Covers, Timing Cover and Water Pump

- ARP Fasteners Throughout, Polished SS Fasteners where Visible

- Powermaster Polished 100A 1-Wire Alternator

- March Polished Accessory Drive

- McLeod Street Twin Dual Disc Clutch with Aluminum Flywheel

- Powermaster Hi-Torque starter

- Lakewood Safety Bell Housing, Modified for Cobra Ground Clearance

Here's some pictures of the finished motor. It went into an ERA Cobra:

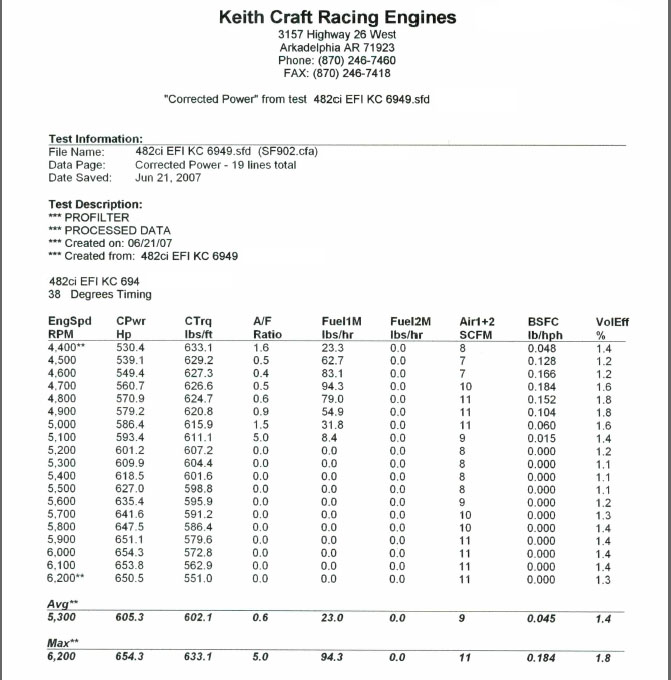

Here's the dyno sheet for Keith's engine dyno:

I have been very pleased with this engine. The drivability with the EFI system and the TWM setup is excellent (no problems cruising the car at 1500 RPM for example) and the throttle response and power are really excellent. I did switch from the Shelby polished valve covers to a black set for appearance reasons and I suspect the McLeod dual-disc clutch is a little much for my application. I also decided to use an MSD Digital-6 box instead of the MSD 6AL that Keith supplied with the motor as the Digital-6 is more easily adjustable, has a 2-step limiter, and provides higher output. MSD's new 6AL-2 would provide all of this functionality and has the same performance as the Digital-6. Other than those items, I would not change a thing. BTW, some tell me that the McLeod dual disc clutch feels a little heavy in the car. Personally, this does not bother me and I don't notice the clutch as being any stiffer than many single disc street/strip clutches I've used in the past. I just got my car finished late last year and I am still doing some tuning work. I sent my FAST system back to FAST and had it upgraded to include Electronic Traction Control (ETC, this requires a driveshaft sensor which I've installed on the car). I expect to do some tuning on the ETC setup in spring to see how well it will work on my Cobra. The FAST ETC system senses a sudden jump in driveshaft RPM when the rear wheels start to spin and takes timing out of the motor to reduce torque output. It will be interesting to see how well this works in a light car like the Cobra in the lower gears.

You can check out my website for more information on the motor and ERA that its in at:

http://www.anitafred.net/Cobra.htm

There's also a pretty complete build thread on the ERA forum which has alot of details on my setup as well. That thread may be found at:

ERA 753 - Final Assembly in Progress

If you decide to do an Aluminum 482 motor, I suggest you give Keith a call. I was very pleased with the work the he did on my motor and will likely work with him again for any future Ford projects that I do.

- Fred