Quote:

Originally Posted by StreetSnake

I have a 427 W with a TWM stack EFI. When the car has been sitting, overnight lets say, I try to start it and it backfires through the throttle bodies. It does this once or twice and then fires up. When the engine is warm it doesn't do it.

I turn power on, wait for fuel pump to cycle, crack the throttle and fire. I don't have an IAC plate on the stacks and that is why I crack the throttle. Is it that or is it timing, I'm at a loss and so is the guy that tunes my car. Any thoughts?

|

Take a look at your timing table (you'll need a laptop for this). Assuming you are using speed density mode, the starting cells would be the lowest RPM columns and the top 5 or 6 load cells. These cells should be set at around 15 degrees. This will allow the engine to crank easily and start fine.

This said, I doubt your issue is timming. There is usually a pre-start (cranking) fuel table that controls how much fuel the engine gets before it starts. This table is usually set up to control the cranking injector pulse width as a function of the engine's coolant temperature. My guess is that your calibration in this table is too lean when when your engine is cold. This causes a lean backfire the first few times you crank and try to start the motor. There is some called Tau that relates to how much fuel dropplets are built up on the walls of your intake manifold. The fact that there is no Tau when you first try to start yoru engine cold is probably contributing to the the likely lean backfire problem that you are having. After you crank a few times, you build up some fuel on the intake runners (Tau) which causes the engine to be a little richer and it will then start. The solution is to adjust your cranking fuel table in the cold start temperature range to increase the cranking pulse witdh and richen things up a little bit.

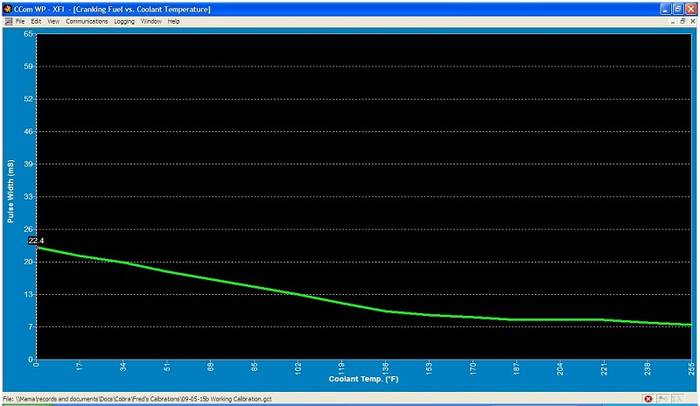

What kind of computer do you have? If you have a FAST system, send me your calbration file via a private message and I will take a look. I would suggest increasing the cranking pulse width about 5% from 85 degrees on down. Save your initial tables first make the change and smooth out the curve in that table and see if you car starts better. If this helps but you still have some problems or you need to crank a long time when the motor is cold, increase the pulse width a little more and try again. If you see black smoke when you start cold or the motor seems to "load up", you've gone too far with the pulse width increases. Remember that you have to wait for the motor to completely cool to test this after you make a change. Just do a moderate amount of increase at a time until you problem is solved. Here's what my cranking fuel table looks like (I have a 482 ci FE with a TWM setup and a FAST XFI computer). You should use this for reference only - my injectors are probably a different size and flow rate (and my displacement is different) than yours so my pulse widths would not be right for you engine. Note how the curve rises smoothly with lower temperature. You want to increase the pulse width by a constant percent from the temperature where you cold start problems are hapenning on down and then smooth the curve from that point up to the hot start termperature such that you don't add pulse width in the hot start zone.

BTW, when all of this is set right, you probably should not need to crack the throttle to start the motor. Your closed throttle idle setting should probably give you enough air to start unless its really cold. If you have trouble getting the motor to idle fast enough to warm up once it starts, there are other tables to look at and you might also consider some idle timing trim if your computer can do this but that is probably another post...

I hope that this helps you. Let me know how this works out.

- Fred