Well, first I did a more careful mileage run and I find I am getting more like 14 MPG. Still pretty good for a 482 ci engine. The mileage is largely due to the combination of the overdrive transmission (My 5th gear is a .64 overdrive) and the EFI system on the car.

I really love driving this car! It handles great, looks great and really performs when you get into the throttle. With the Goodyear billboards, it also does pretty well in the turns

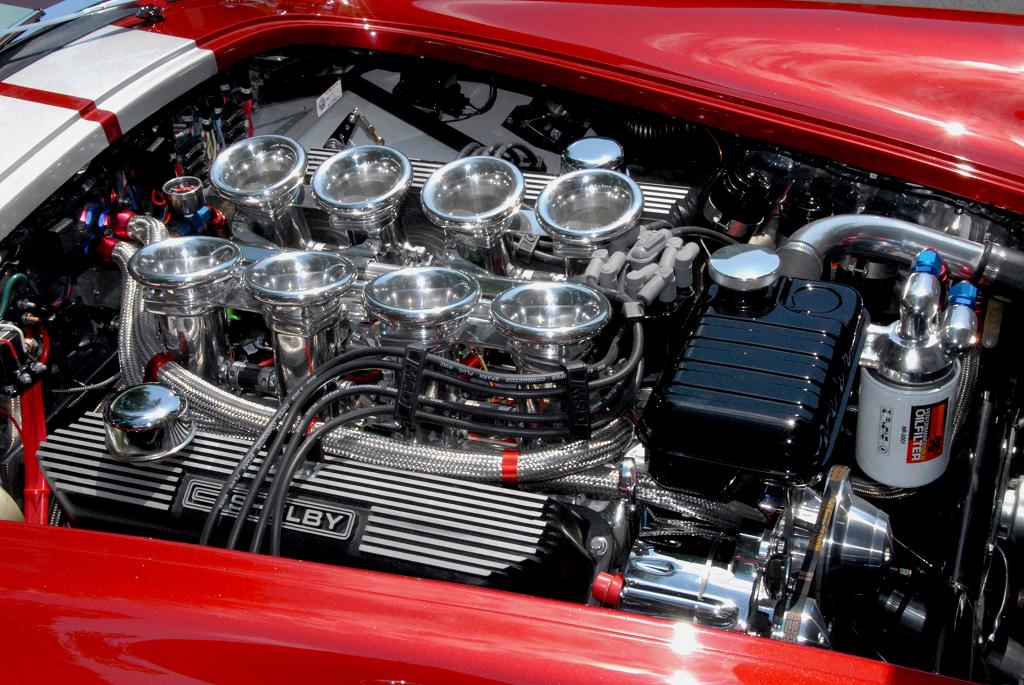

. As Ron knows, I am a big EFI fan and would probably not build another carburated performance engine for the street at this point. While EFI results in more up front cost and work to install, it really is great to be able to jump in the car and just drive it without any finicky behaviors. The other advantage of EFI is that it allows more radical induction and camshaft combinations to be used with good drivablity on the street. The following pics are of the induction systems on my two EFI street motors:

482 ci Injected Ford FE

383 ci Blown and Injected SBC

I've started these motors in cold weather (as low at 0 degrees with the blown and injected car) and they start right up and idle perfectly. The drivability on both motors is excellent (although they do take a very LIGHT touch on the throttle to cruise due to the large amount of throttle blade area). BTW, both of these motors make over 600 hp and 600 ft-lbs of torque on 93 octane pump gas.

I doubt that either of these motors would be as streetable as they are without the associated EFI systems.

As far as tuning goes, I personally find EFI system much easier to tune then carbs. With an EFI system, a tuner can make very localized changes in the fuel and timing curves of a motor without having an effect anywhere else in the engine's operation. This is a big advantage over a carb where changes effect large areas of the fuel delivery and timing curves. In the later situation, solving a problem at one point in an engine's operating range can often cause problems in other areas or a power or drivability loss overall. I recently took an advanced EFI tuning course where we spent a full day optimizing the performance of a car on a dyno. Based upon this experience, I can definitively say that an EFI equipped car when optimally tuned using a load bearing dyno, will outperform a carb equipped car in at least some areas of the engine operating range. The reason for this is that the combination of a carb and a manual/vacumn advance distributor can at best provide a compromise in terms of optimal fuel and timing delivery for a given engine. As an example, it is not uncommon for a motor to want a different timing advance setting than a standard distrbutor can delivery with its relatively fix mechanical and vacumn advance curves. For example, a combination of a somewhat restrictive exhaust system and a high overlap camshaft might result in a great deal of reversion at a specific RPM and load range. In an EFI system, it is very simple to give the same motor the exact amount of extra timing and fuel that it wants to address what would otherwise be a drivability issue in a situation like this at only the required combination of engine load and RPM. Fixing this sort of a problem with a carb would likely result in an overly rich mixture in a large are of the engine's operating range and it may be impossible to add the optimal amount of ignition timing without causing the engine to detonate just above the range where the reversion problem ceases. The more radical the combination of camshaft and induction becomes, the more likely the these "fine point" optimizations are going to be important for good drivability somewhere in a egine's operating range.

Modern engine management systems also allow for some capabilities that would be very hard to duplicate without them. For example, our cobra has an electronic traction control system which is part of the engine managment system. This setup uses a driveshaft speed sensor which detects when the rear wheels are spinning and reduces the ignition advance and therefore the torque output of the motor. The result is that I cannot spin the rear tires on a hard start unless I really try. These sorts of capabilities make the car more fun to drive. Another example would be that the EFI setup on our cobra has a total of 4 seperate tunes which can be selected with a switch. This allows me to have a tune that would be optimized for a different grade of fuel (say race gas where more ignition timing would be needed) and either tune can be selected with a flip of a switch.

Then there is the on-board data recording capabilities that come with most EFI systems. It great to know that I got to 100 MPH while pulling .7-1.5g's in a certain amount of time and be able to see how quick my shifts were and what my instaneous MPG readings were in the process (well maybe the MPG in these situations is somewhat depressing ....).

Some folks suggest that only an engineer (I am an EE) could make a modern EFI system work really well. I would say that installing a good EFI setup is certainly no more difficult that building the cobra's that many of us on this forum have done. The technology is new but can easily be learned with a little reading and investment in time. There are also more and more qualified performance EFI tuners every day so one does not need to be an expert to get a EFI equipped car properly tuned and running great. The really nice part about the tune is that it will need to be done only once in the life of the car/motor unless something significant is changed so this step can be outsourced to an expert. The other factor is the higher initial cost of an EFI system. I personally think this issue is somewhat overblown because many folks who build an EFI equipped car are doing so to run a radical (and fundamentally more expensive) induction system than a carb. I think if one compares a basic EFI system with a carb like intake and throttle body to a comperable carb induction setup, the premium paid for the EFI setup becomes much smaller. If you add the time and expense to keep the carb running at peak performance over the life of the combination, I would suggest that the cost difference become next to nothing.

As engines become more sophisticated, it is only a matter of time before modern engine management systems become essential to extracting peak performance. A good example of this is the recent application of Variable Valve Timming (VVT) technology to performance engines. VVT is a system that varies cam timing, overlap, and or valve lift under computer control. Many modern (post 2000) automotive engines are using some form of this technology to increase power output, mileage, and emissions performance. I recently saw test results from an application of this technology to a performance motor and gains in the range of 10% torque and HP at some points in the engine's operating range were achieved with VVT under the control of an aftermarket EFI system. The bigest advantage of VVT in performance applications is that it creates a broader, flatter torque curve. Also note that the 2008-2009 Viper V-10 engine uses a VVT system and an EFI management computer which together with a power adder can make over 700 hp (the "stock" V-10 with VVT makes 560 ft-lbs and 600 hp).

Sorry for the long article on the merits of EFI but I believe that this choice has alot to do with the "fun factor" of owning and driving our cobra. The last thing to mention is that an EFI system can be installed on a classic car in a way that maintains the original retro look of the vehicle in question. In both of the pics above, the EFI elements have been well hidden and the cars look pretty close to period correct when compared to the far less drivable mechanical induction systems equivalents that would have been used in the day.

- Fred