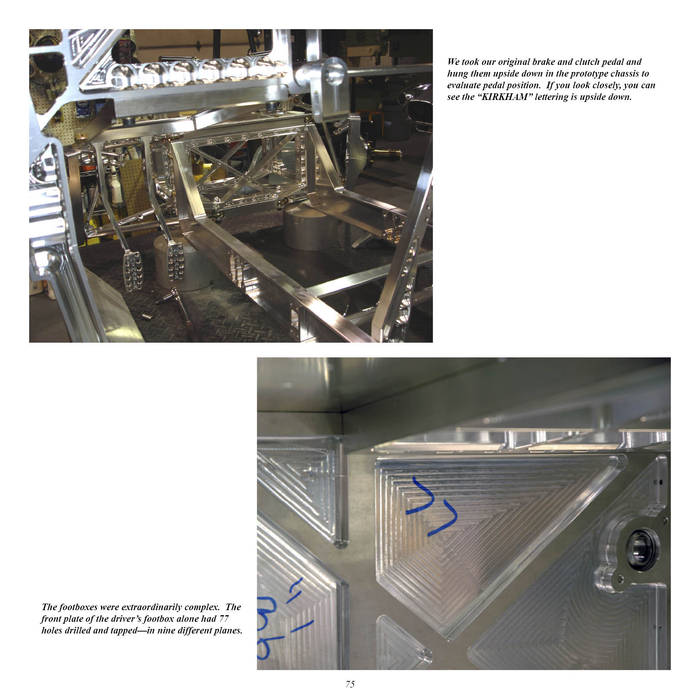

The upper picture shows prototype cowl structure. Notice the firewall was not milled directly into the part. After riveting a sheet of aluminum onto the part I told myself, "This is dumb!" So, we machined the "sheet metal" right into the part on the next iteration. In the lower photo, the number "77" in blue magic marker shows how many holes had to be tapped and drilled into the driver front plate in the footbox. 9 different surfaces had to be thought about while making the part.