Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

06-24-2010, 01:17 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

How big an issue are slipping balancers?

How big an issue are slipping balancers?

I had a conversation a few days ago with someone who has been involved in building and tuning carbs/engines for 25 years.

He told me that our industry suffers significantly from slipping balancers that combined with an over-reliance on timing lights meant that we were making the job of tuning an engine way harder than it needed to be because the timing we were reading was not necessarily accurate any longer. He advocated tuning by ear and turning the distributor until the engine idled best and then driving it to make sure it didn't ping/knock. And maybe using the timing light as a nominal reference to make tweaks at that moment, but not for comparative purposes later.

The result is that we chase down all sorts of other "issues" when the timing isn't actually optimal and is causing whatever problem you are trying to "solve".

I don't remember seeing any threads on this (although I'm sure there have been), so I thought I'd throw it out there.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

06-24-2010, 01:32 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

He advocated tuning by ear and turning the distributor until the engine idled best and then driving it to make sure it didn't ping/knock.

|

Yeah, it's called "timing by detonation" and you only do it when you have no marks or you're sure your marks are wrong. Shoe does it on one of his engines over on the FordFE forum but only because his dampner got munged. He talks about it in this thread:

http://www.network54.com/Forum/74182...J+distributor- I just set my timing mark on my pointer earlier this week with a piston stop (because it changed with my new dampner). It took less than a half hour to get it dead on, I didn't even have to jack up the car, and I didn't rotate the engine backwards either -- I'll lay out the steps if you want me to -- it's very straight forward. IMO, you only use TBD when you have no other choice. |

06-24-2010, 02:20 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

I highly doubt mine is slipping since it less than a year old, but I thought it was an interesting question. How big an issue are slipping dampners? Not likely? Or more pervasive than we might think?

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

06-24-2010, 03:55 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

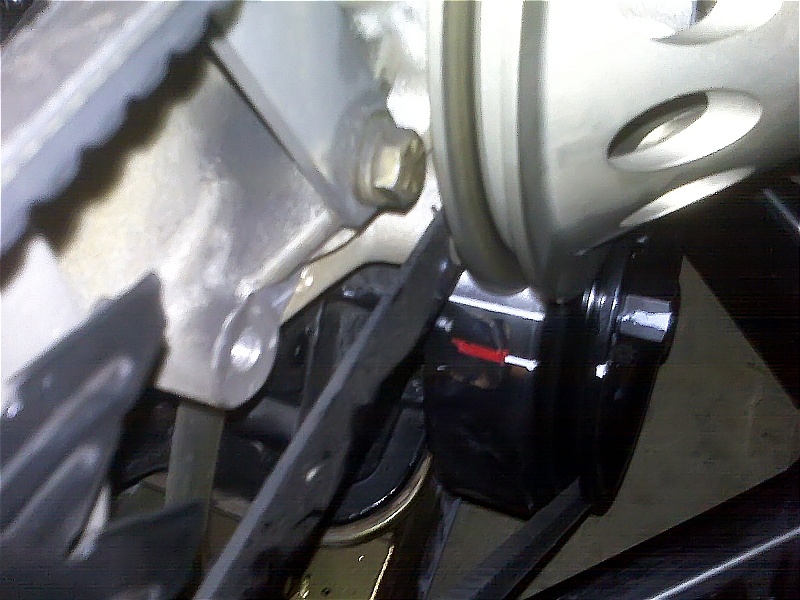

One member emailed me when I was replacing mine and reported that a slipped dampner caused significant damage to his engine (because he kept advancing the timing). I have another cronie who spends a lot of time drag racing and he reports that it is not uncommon there. Spend two bucks on a piston stop and then one Saturday when you have nothing to do double check your TDC and put a paint line on your crank pulley and bolt. It couldn't hurt. That bottom shot is of my engine at TDC.

Last edited by patrickt; 10-24-2016 at 01:31 PM..

|

06-24-2010, 04:09 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

didn't rotate engine backwards????Maybe you better lay out how you did it!!!!!

|

06-24-2010, 04:22 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jerry Clayton

didn't rotate engine backwards????Maybe you better lay out how you did it!!!!!

|

1) Put a pointer, any pointer, aimed at an easily reached spot on your dampner.

2) Put a stick in your #1 spark plug hole and using your wrench on the crank bolt, rotate your engine until you are just past TDC (piston is heading back down the hole).

3) Remove your stick and insert your piston stop and screw the little screw part down until it touches the top of your piston and goes no further.

3) Put timing tape on your balancer with the zero degree mark aimed at your make shift pointer.

4) Rotate the engine in the normal direction all the way around until it stops again because of the piston stop. Note the degree that the pointer is aimed at (for instance, 24 degrees). Divide that number by two (12 degrees).

5) Remove your piston stop and rotate the engine a little bit farther to that number (in this example, 12 degrees).

6) You are now at TDC. |

06-24-2010, 05:07 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2007

Location: Covington,

wa

Cobra Make, Engine: Superformance # 532, 466 BB, 560HP

Posts: 3,029

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

1) Put a pointer, any pointer, aimed at an easily reached spot on your dampner.

2) Put a stick in your #1 spark plug hole and using your wrench on the crank bolt, rotate your engine until you are just past TDC (piston is heading back down the hole).

3) Remove your stick and insert your piston stop and screw the little screw part down until it touches the top of your piston and goes no further.

3) Put timing tape on your balancer with the zero degree mark aimed at your make shift pointer.

4) Rotate the engine in the normal direction all the way around until it stops again because of the piston stop. Note the degree that the pointer is aimed at (for instance, 24 degrees). Divide that number by two (12 degrees).

5) Remove your piston stop and rotate the engine a little bit farther to that number (in this example, 12 degrees).

6) You are now at TDC.

|

Don't forget to remove all of the spark plugs. Engine rotates easier, and you won't have an compression issues trying to rotate the engine also.

__________________

John Hall

|

06-24-2010, 05:10 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Silverback51

Don't forget to remove all of the spark plugs. Engine rotates easier, and you won't have an compression issues trying to rotate the engine also.

|

I don't even bother removing the plugs. I slip the four foot long aluminum handle from my jack over my ratchet wrench and then just rotate it slowly. It makes for a very easy job. |

06-24-2010, 05:57 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Did you move your timing tape after you got to step 6?

|

06-24-2010, 06:02 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

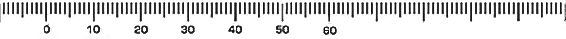

... and you can use any old timing tape, it doesn't have to be the exact size for your dampner since you're only using it to "split the difference." For that matter, you can just print this out and use it. Now c'mon, that's pretty darn simple.

Last edited by patrickt; 10-24-2016 at 01:32 PM..

|

06-24-2010, 06:05 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Glad your happy with it, but repeatedly guys will be off 2 - 4 degrees doing it that way

The only positive way is to use a positive stop which will require rotation both ways against the stop---and removing all the plugs makes it much easier as you have more feel with your 6 foot jack handle

|

06-24-2010, 06:08 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jerry Clayton

Glad your happy with it, but repeatedly guys will be off 2 - 4 degrees doing it that way

|

I don't believe that. I think it will be dead on if you do it carefully. My timing was exactly where it was on my new dampner, after setting it, as it was on my old dampner, right before it failed. Right on the money, not a degree off. |

06-24-2010, 06:11 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Believe what you want but if you ever start wrenching on real race or hi per engines where a degree makes a differance-----

|

06-24-2010, 06:16 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Patrick,

Chances are that you did ok. However, for future times if you're changing balancers or degreeing a cam, Jerry makes a good point. You need to have as least rotating resistance possible and IMO you need to bump the stop twice.....once forward and once backwards.

|

06-24-2010, 06:26 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Patrick---I rereaD MY POST AND IT MIGHT HAVE COME ACROSS A LITTLE STRONG---SORRY about the caps---

You will be fine on running your engine from whatever marks you make as you will have repeatability on your engine---however, my point is that if you are going to deal with several engines you must have a system that is absolute for the repeatable results as you tune after any changes to the engine or possibly on other cars( multiple cars/engines)

|

06-24-2010, 06:30 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

No worries. The only Cobra I work on is my own -- and all too much it seems. But back to the original thread. Do you have any thoughts on Doug's concerns over slipping dampners? Obviously I'm a little prejudiced on the issue having just changed mine out last week.

|

06-24-2010, 06:35 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

They slip.....especially old stock ones. But it's easy to verify and correct if necessary.

|

06-24-2010, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Yes--

They will fail and slip if they have had to actually dampen harmonics over a period of time---could be a few seconds or several years--

Harmonics can come from several sources----there are several orders within the engine itself, and also is extended thru out the complete driveline---driveshafts on cobras are quite short and angles are severe--half shafts--wheel balance/wobble, etc

For an example of several years---Ford pickups have a terrible front end ball joint problem, which causes errattic tire wear---rotate those shaking tires to the rear and they create a harmonic vibration back up thru the drive shaft killing the harmonic dampener!!!!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:11 PM.

Links monetized by VigLink

|