Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

02-23-2011, 02:28 PM

|

|

CC Member

|

|

|

Join Date: Jun 2004

Location: Leicestershire,

UK

Cobra Make, Engine: Kirkham #523, 427 S/O

Posts: 1,137

|

|

Not Ranked

Not Ranked

Bump Steer

Bump Steer

I've come up with a really simple way to measure the bump steer on my car, but I won't disclose it until I have tested my methodology.

However, I would like to know what level of bump steer is considered good. Obvious zero is best, but how close do I have to be to zero before I can stop adjusting?

Thanks,

Paul |

02-23-2011, 03:45 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: San Diego,

CA

Cobra Make, Engine:

Posts: 2,979

|

|

Not Ranked

Not Ranked

Obviously less it best but you also don't want to cross that line from toe-in to tow-out or vice versa in your suspension travel.

__________________

Remember, It's never too early to start beefing up your obituary.

|

02-23-2011, 04:17 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

I think it would also be good to discuss the causes of bump steer.

|

02-23-2011, 04:17 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

i think it is a complex adjustment, depending on the total suspension package. from run a car with toe out and on dive toes in for more stability to check or adjust bumpsteer with the wheels turned as this is where it is happening to simple adjust for .040 toe out per in. bump. generally.

|

02-23-2011, 04:45 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

"My recommendation is to run .005 to .015 thousands of bump out but never allow the tires to bump in." http://www.longacreracing.com/articles/art.asp?ARTID=13

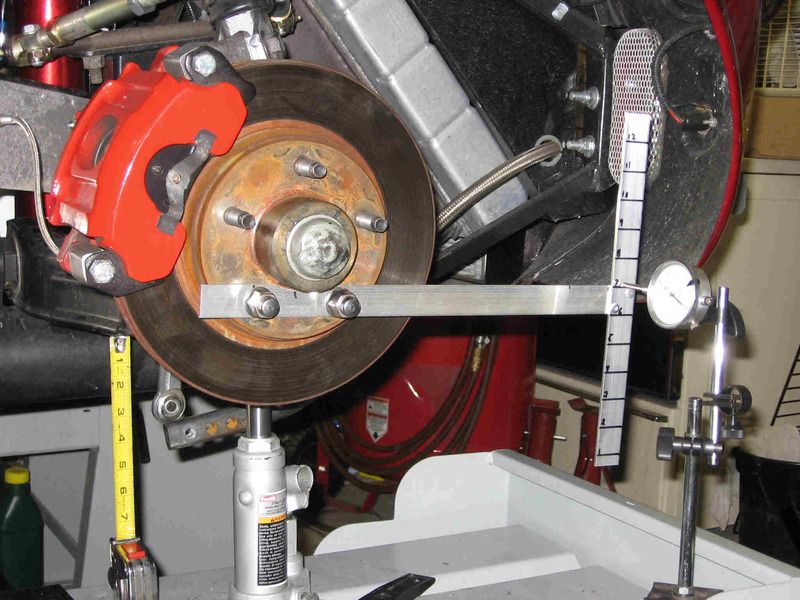

Here's how I measured mine.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

02-23-2011, 05:11 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

I guess my point is it would appear much of the bump steer is from bad design. Lower A arm should be close to level as possible at ride height. The upper A arm should be parallel with the lower. There should be an imaginary line between the inside upper A arm pivot point, the steering rack inside tie rod end pivot point, and the lower A arm inside pivot point. This will allow for a constant arch as the suspension moves up and down. One common mistake is the wrong length steering rack that is not in line with the other A arm pivot points or a rack that was shifted to one side for the steering shaft to clear the frame. When it is not in line it pulls the tire in and out as it arch’s through the travel. Obviously there are other causes, but this is a big one.

|

02-23-2011, 06:10 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Location: centralia,

IL

Cobra Make, Engine: B&B cobra (sold), Hurricane HMS1002 (sold), Kirkham 289 FIA, (sold) RCR GT 40(sold) SPF GT40 2122(sold) Hurricane HMS2002, (sold) RCR SLC (sold) GTR on the way!

Posts: 1,288

|

|

Not Ranked

Not Ranked

The general rule of thumb is .020 per inch up or down. Bob, I'm not sure the gauge in the picture will give you the answers you need. As the wheel moves through its motion it will move in and out because your control arms move through a natural arch. To measure how much the toe changes, you would need to place your dial indicator in the front(as you have it) and one in the rear. As the tire moves, measure the change front and rear then subtract one from the other. That is your bump steer number. Here is my tool for measuring bump steer. Even if the front gauge and the rear gauge move out .090, but move the same amount, you have 0 bump steer.

__________________

High Maintenance Racing Team

Run & Gun 2003 - 2013

|

02-23-2011, 06:30 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dlampe

The general rule of thumb is .020 per inch up or down. Bob, I'm not sure the gauge in the picture will give you the answers you need. As the wheel moves through its motion it will move in and out because your control arms move through a natural arch. To measure how much the toe changes, you would need to place your dial indicator in the front(as you have it) and one in the rear. As the tire moves, measure the change front and rear then subtract one from the other. That is your bump steer number.

|

It works pretty well. I only own 1 dial indicater. So first I measure the front, and write down the numbers for every inch of movement. Then I flip it over, and measure the back in the same way. Then, just like you, I subtract one from the other.

My bumpsteer varies from 0.005-0.010", all toe out, no toe in.

The trick, I think, with measurements this precise is to do it 4-5 times, and make sure they're repeatable and consistant.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

02-24-2011, 08:59 AM

|

|

CC Member

|

|

|

Join Date: Jun 2004

Location: Leicestershire,

UK

Cobra Make, Engine: Kirkham #523, 427 S/O

Posts: 1,137

|

|

Not Ranked

Not Ranked

I should point out that at the moment, I'm working on the rear wheels.

I'm making adjustments by moving the top wishbone forwards i.e. towards the front of the car.

I'm not clear in my own mind what this is actually doing to the suspension geometry, but it does seem to be having the desired effect on the bump steer.

Paul

|

02-24-2011, 07:21 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Location: centralia,

IL

Cobra Make, Engine: B&B cobra (sold), Hurricane HMS1002 (sold), Kirkham 289 FIA, (sold) RCR GT 40(sold) SPF GT40 2122(sold) Hurricane HMS2002, (sold) RCR SLC (sold) GTR on the way!

Posts: 1,288

|

|

Not Ranked

Not Ranked

All the post's above still apply to the rear. The longer the control arms, the less you will see the effects of bump steer. In many cases, that is why the back of our cars has less bump steer than the front. Just make sure you use a very good plate to measure off of. If there is the slightest bend in the piece of steel/aluminum that is bolted to the wheel, it will screw up you numbers. This is an important step that is often over looked.

__________________

High Maintenance Racing Team

Run & Gun 2003 - 2013

|

02-26-2011, 02:17 PM

|

|

CC Member

|

|

|

Join Date: Jun 2004

Location: Leicestershire,

UK

Cobra Make, Engine: Kirkham #523, 427 S/O

Posts: 1,137

|

|

Not Ranked

Not Ranked

I've made some more measurements and I now feel reasonably happy to post the results.

Here is a picture of how I made the measurements and it really is very simple and very cheap to do.

I fastened a Bosch laser level (cost about $30) to the brake disk using a velcro tie strap. The side of the laser level has a flat machined surface ideal for this purpose. This laser "draws" a line rather than a dot and you can see the red line on the piece of aluminium on the floor. I drew two lines on the aluminium perpendicular to the laser line 30" apart (2 x wheel diameter).

I then used the trolley jack to set the suspension at normal ride height, having first disconnected the lower shock absorber mount. Where the laser line crossed the two previously drawn lines I used a fine scribe to mark the exact position. The procedure was repeated with the suspension at 1" and 2" above and below the normal position.

I now had five scribe marks on each drawn line. I then used a set of vernier calipers to accurately measure the distance between each corresponding pair of scribe marks and subtracted one from the other to get the deviation (toe-in or toe-out) then divided by 2 to get the deviation for a 15" wheel (remember, the scribe marks are 30" apart).

Here is a chart showing two sets of results, the second one after a very minor suspension adjustment.

With care, I believe it is possible to measure to within 0.002" using this method.

I have taken multiple measurements of the same suspension setup and I am happy that the results are repeatable.

Of course, the further apart the guide lines, the more accurate the results. I had to rotate the wheel slightly each time in order for the laser line to reach the ends of the 30" scale, but this doesn't effect the results at all.

I hope this helps someone.

Paul

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:06 PM.

Links monetized by VigLink

|