Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

07-24-2013, 05:48 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Recovery tank issues

Recovery tank issues

Hey everybody,

I have an old 351 Windsor with a coolant system straight out of sci-fi movies.  At least I think it is. There's a recovery tank bolted to the thermostat housing on the intake manifold. Two 3/8-16 bolts is all she has to hold together. I've tried two different thickness gaskets made from cork/rubber that I've cut to shape and two thin paper gaskets with RTV and so far none of them have held up to the vibration/lumpy idle. Two bolts! If I under-torque the gasket blows, if I over-torque it squeezes too much and ruins the gasket not to mention the possibility of stripping threads. Any suggestions out there for a permanent fix using the current tank? The manifold is a Victor Jr. Thanks for any help.

|

07-24-2013, 05:53 PM

|

|

CC Member

|

|

|

Join Date: Nov 2007

Location: Clayton,

IN

Cobra Make, Engine: ERA 838

Posts: 1,125

|

|

Not Ranked

Not Ranked

FEs only use two bolts and hold up fine.

Are both surfaces flat? Check them with a straight edge. I use a 6" scale.

John

|

07-24-2013, 06:00 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

i wouldn't use the cork. you can use a paper gasket or not, but get some of 'the right stuff' gasket maker and smear a thin coat on the tank, both sides of the gasket if you use one, but it should be thin. put some on the bolts to hold them in and put it all together with about 12-15# tq. let sit overnight. also make sure surfaces are clean and flat. also make sure your bolts are not bottoming out but give you the longest reach you can use, might have to stack washers if the bolts are too long.

|

07-24-2013, 07:10 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Thanks for the suggestions, fellows. I have checked both surfaces and ensured their flatness by running a coarse-grit stone over them while thoroughly cleaning all residue. I've used the paper gasket twice but didn't use the gasket sealer you mentioned or checked bolt depth. I know I've got good pressure from seeing the deformed cork but haven't measured to the bottom. I guess that's next.

Any thoughts on machining an o-ring grove on the flange side of the recovery tank and using a high pressure o-ring? Thanks!

|

07-24-2013, 07:57 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Location: McMurray,

PA

Cobra Make, Engine: Superformance #522

Posts: 528

|

|

Not Ranked

Not Ranked

Bolt holes are perpendicular to gasket surface? Are you using lock washers ? Thermostat housing interfering with tank?

Last edited by vatdevil; 07-24-2013 at 08:03 PM..

|

07-24-2013, 10:08 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Yes to both questions. Not only a lock washer but a crush washer to take extra torque. I don't think there's any interference. Has anyone out there had problems like this with their recovery tank or are most folks with a 2 hole bolt pattern sealing just fine without incident? How about that o-ring groove... or maybe adding a third fixation point somewhere for stability? Just wondering.

BTW, anybody running without a thermostat? I have a 160 and 180 degree and have tried both. Just wondering about others experiences.

Thanks.

Last edited by kniteridr60; 07-24-2013 at 10:11 PM..

|

07-25-2013, 05:07 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Windham,,

Me

Cobra Make, Engine:

Posts: 1,590

|

|

Not Ranked

Not Ranked

Keep this in mind everytime you torque these bolts down you are shearing a little more of the threads in the aluminum manifold.You will eventually need thread repair.Is there a place you could bolt a support bracket/strap for the tank to help absorb the vibration?

There is an aircraft gasket sealer use it on both sides of a paper gasket give it 24 hrs to cure it should hold.

|

07-25-2013, 06:00 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,525

|

|

Not Ranked

Not Ranked

If you have heater hoses you might check the nipple right behind the distributor to make sure it isn't leaking from there. I thought I had a leaking thermostat/expansion tank gasket and realized after replacing it that it was my heater hose shutoff valve threaded into the intake hose nipple boss that was leaking and running down around the thermostat.

|

07-25-2013, 11:48 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

My thoughts exactly, mdross1. Based on messages thus far it sounds like I have somewhat of an exclusive issue. Hmmm.

DanEC, thanks for the suggestion. I've literally had coolant spray out at me when hot and under pressure from that gasket leaking, so I know where it's coming from... kind of like a pin hole in a water balloon. Appreciate the suggestion though.

Does anyone have a suggestion about a place you could bolt a support bracket/strap for the tank to help absorb the vibration?

|

07-25-2013, 12:11 PM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Location: McMurray,

PA

Cobra Make, Engine: Superformance #522

Posts: 528

|

|

Not Ranked

Not Ranked

Put in a Kirkham tank. Or remove tank and install in line filler tee.

|

07-25-2013, 04:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,601

|

|

Not Ranked

Not Ranked

The problems sounds like ..you..forgot to put gasket sealer/ silicone...on the paper type gasket. Try again and use the sealer......  |

07-25-2013, 06:14 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Perhaps I used the wrong terminology... I used Permatex Form-A Gasket Sealant... twice... on both sides of the paper gasket. Let sit for minimum 8 hours (more like 12-14). Torque could be a key though. Thanks for the suggestion. Sounds like everybody is steering me back to the original application, cleaning/wiping thoroughly, make sure the bolts seat and apply 12-15 # torque.

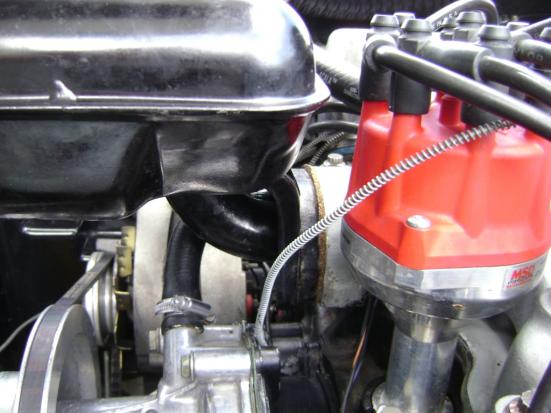

On another topic, can somebody explain to me the reason why I have an overflow tank besides a recovery tank? And the overflow has a valve for draining at the bottom. And it fills up occasionally and comes out a weep hole in the top? (See the pic) Why doesn't it re-rout back to the rad? Just so you know, I bought the car three years ago with the current config and it's given me nothing but grief the whole time.  |

07-26-2013, 02:47 AM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Location: McMurray,

PA

Cobra Make, Engine: Superformance #522

Posts: 528

|

|

Not Ranked

Not Ranked

The coolant tank exists to provide a filling point and a means for air to escape out the system. Otherwise, air would trap in the radiator, since its not the high point.

The overflow tank is just that, a tank to catch overflow coolant so it doesn't spill out onto road surface. The valve is used to drain the overflow tank so it doesn't push out the weep hole. If coolant pushes out the weep hole you are probably overfilling the system. Only need to fill the coolant tank halfway.

|

07-26-2013, 06:05 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,525

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by vatdevil

The coolant tank exists to provide a filling point and a means for air to escape out the system. Otherwise, air would trap in the radiator, since its not the high point.

The overflow tank is just that, a tank to catch overflow coolant so it doesn't spill out onto road surface. The valve is used to drain the overflow tank so it doesn't push out the weep hole. If coolant pushes out the weep hole you are probably overfilling the system. Only need to fill the coolant tank halfway.

|

Unless the overflow tank is actually a recovery tank. Then you could put a recovery system type radiator cap on the expansion tank and fill it full. |

07-26-2013, 07:26 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

your overflow tank is incorrect, the inlet from the header tank (what you term recovery) should go into the bottom, invert your overflow and open the bleed for air or take it out completely and insert a barb with another hose to bottom of chassis for overflow.

unless the inlet to the overflow has a tube inside that goes to the bottom of the container, then disregard. but you still need an air bleed on it.

actually, putting a header tank on the pressure side is a bad design,........ but everybody does it.

Last edited by vector1; 07-26-2013 at 07:28 AM..

|

07-26-2013, 09:11 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Thanks for all the suggestions, guys. Question: If I have the proper amount of coolant circulating throughout the system, should the overflow tank fill at all?

|

07-26-2013, 09:58 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by kniteridr60

Thanks for all the suggestions, guys. Question: If I have the proper amount of coolant circulating throughout the system, should the overflow tank fill at all?

|

it will because it is on the pressure side, but if set up correctly it should be able to pull the coolant back into the system. |

07-26-2013, 12:11 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Cobra Make, Engine: SPF#0760

Posts: 3,405

|

|

Not Ranked

Not Ranked

It appears that you have a JAZ overflow tank. They are available in two styles; a simple tank and a reservoir/return tank. Difference being a simple tube connected to the top fitting of the overflow tank that extends to the bottom of the overflow tank. I believe the top fitting is held in place with a simple o-ring. As I recall, you can remove the top fitting and add a section of tubing inside the tank. Feel free to contact me I may have a photo. The SB expansion tank has a spacer for a tank brace that helps to support the tank from engine vibration. I have a Technical Service Tip covering the SB installation of the tank that you may find interesting. Drop me an email offline and I'll send you a copy. I'll look to see if I have anything related to BB tank installation in my reference files.

BTW: In looking at your earlier photo, the sensor tube for the water temp gauge appears dangerously close the distributor cap and wires. I would suggest that you consider carefully adjusting the routing of the coil-wrapped sensor tube away from the distributor and plug wires, and then get a short section of clear tubing (like fish tank air tubing) - slit it length wise - and put it on the sensor tube where it comes close to sparkplug wires and the cap. Why? Because one spark that would jump from a sparkplug wire to the sensor tube, could put a tiny hole in the sensor tube that will allow the gas inside to escape, rendering the temp gauge useless and your wallet a little lighter when you replace the gauge.

__________________

Wiring Diagrams: SPF MKII, MKIII, GT40, CSX7000, CSX8000, Corvette Grand Sport, and Shelby Sebring, Bondurant & Cinema Tribute Cars.

Owner’s Manuals: SPF MKII, CSX7000, CSX8000, Sebring, Bondurant, Cinema Tribute Cars $ GT40’s..

Large, easy to read and trace schematics with part numbers, wire colors, wire gauge, fuses, and electrical upgrade information. Trouble-shooting and replacement part numbers for those roadside repair adventures.

SPFWiringDiagrams@Comcast.net

Last edited by Blas; 07-26-2013 at 12:24 PM..

|

07-27-2013, 11:09 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Brighton Twp.,

PA

Cobra Make, Engine: Superformance with modified 351 Windsor

Posts: 44

|

|

Not Ranked

Not Ranked

Well, Mr. Blas, you hit the nail ON THE HEAD about the sensor tube... and I was two weeks late. I noticed a slowly dying water temp gauge since then and last night she gave up the ghost completely   So my wallet shall become lighter as you say. Can the gauge be repaired rather than replaced? Thanks for the advice! |

07-27-2013, 02:54 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Cobra Make, Engine: SPF#0760

Posts: 3,405

|

|

Not Ranked

Not Ranked

Drop me an email offline. My contact in is below.

__________________

Wiring Diagrams: SPF MKII, MKIII, GT40, CSX7000, CSX8000, Corvette Grand Sport, and Shelby Sebring, Bondurant & Cinema Tribute Cars.

Owner’s Manuals: SPF MKII, CSX7000, CSX8000, Sebring, Bondurant, Cinema Tribute Cars $ GT40’s..

Large, easy to read and trace schematics with part numbers, wire colors, wire gauge, fuses, and electrical upgrade information. Trouble-shooting and replacement part numbers for those roadside repair adventures.

SPFWiringDiagrams@Comcast.net

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:11 AM.

Links monetized by VigLink

|