Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

7Likes 7Likes

02-02-2014, 10:14 AM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

Lippy,

When you did the pre-install assembly and inspection, did you check that the input shaft wasn't bottoming out in the pilot bearing?

|

Bob, Yes I did. I marked the depth in the trans with a dowel, and checked that I had clearance. Thanks. |

02-02-2014, 11:39 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

About the only thing I know about dual disk clutches is that there is some set-up and shimming that needs to be done on the clutch assembly (or at least checked and verified) to provide proper air gap when the clutch is pushed in. I assume either Brent or you did this?

|

There's only so much I can do here. I put the pivot and fork in the bellhousing, dialed the bell, and bolted up the flywheel/clutch. I have no way of checking gap here since there was no way of actuating the clutch, but everything assembled without issue. The trans was drop shipped to Jeff a few months before the engine got there.

I talked with Jeff as he was bolting up the trans, and we went over checking input shaft depth, and also the fact that the trans should go in without having to pull it in with the bolts.

I'm not sure how much stroke this particular setup is supposed to have, I've seen more out of the slave cylinders I've used. Usually, if everything mechanical is perfect, then it's an issue of air in the line, or the pedal ratio is off. A 3/4" bore master cylinder is about perfect as far as pedal effort goes, but it does require a bit more stroke. |

02-02-2014, 11:59 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Well Lippy - good news on the input shaft depth. Something else you might try is to further adjust the slave cylinder to fork rod to preload the clutch disc significantly - and then push it in and see if the wheels will turn. That will simulate more slave cylinder stroke. If it disengages then you know you need more stroke. With that dual disc clutch you can probably go with a 7/8 inch master cylinder easily (maybe 1 inch) without any problem. I forget what I calculated when I changed mine out but it saved at least an inch of stroke - or in your case will give you an inch more stroke (at the pedal). A screwdriver slot on the end of the rod will help pre-loading the clutch. (remember from earlier post)

Dan

|

02-02-2014, 01:13 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

There's only so much I can do here. I put the pivot and fork in the bellhousing, dialed the bell, and bolted up the flywheel/clutch. I have no way of checking gap here since there was no way of actuating the clutch, but everything assembled without issue. The trans was drop shipped to Jeff a few months before the engine got there.

I talked with Jeff as he was bolting up the trans, and we went over checking input shaft depth, and also the fact that the trans should go in without having to pull it in with the bolts.

I'm not sure how much stroke this particular setup is supposed to have, I've seen more out of the slave cylinders I've used. Usually, if everything mechanical is perfect, then it's an issue of air in the line, or the pedal ratio is off. A 3/4" bore master cylinder is about perfect as far as pedal effort goes, but it does require a bit more stroke.

|

Brent, I'm about 99.99% sure this is me and not you, but I appreciate your expertise. I did check the depth as we discussed. But when I installed the trans, I jacked it up and pushed it onto the shaft (greased lightly as you mentioned). It went on most of the way easily, but I did use the bolts to pull it in about the last 0.5-0.75", turning each slightly and going in a diagonal bolt pattern so it went on straight.

Is there anything I can check besides the slave travel, possibly by looking into the fork opening? I'm sort of at a loss here.

|

02-02-2014, 01:17 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

|

Thanks Patrick, that tool is really cool. It looks like you are getting a lot more travel than I am, but I'm not sure why. I've bled this thing about 10 times and there are no air bubbles and the linkage is tight and responsive. Did you have any issues with the adjustment of your pedal height, and how it impacts cylinder actuation? |

02-02-2014, 02:11 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Jeff, I mentioned this earlier, but did you bleed the master cylinder?

Also, you put the little bit of grease on the bearing retainer of the trans, not the splined shaft itself, right?

|

02-02-2014, 03:30 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

Jeff, I mentioned this earlier, but did you bleed the master cylinder?

Also, you put the little bit of grease on the bearing retainer of the trans, not the splined shaft itself, right?

|

Brent, yes and yes. I feel pretty good that it's not an issue of bleeding. There is no air coming from either the slave or the master when I bleed them, and the hydraulics feel tight and responsive when I engage the clutch. I also tapped the slave and master lightly with a rubber mallet to dislodge any bubbles, and I made sure the bleed screw on the slave is at 12:00. I didn't raise the front of the car, though. |

02-02-2014, 03:45 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

Thanks Patrick, that tool is really cool. It looks like you are getting a lot more travel than I am, but I'm not sure why. I've bled this thing about 10 times and there are no air bubbles and the linkage is tight and responsive. Did you have any issues with the adjustment of your pedal height, and how it impacts cylinder actuation?

|

Other than it all falling apart one day when I was out in Bumfu**? See: Ehhrggg, Standed by a Set-Screw Or when the fork was rubbing against the reservoir of the master? (You've seen that thread.) To answer your question, "No." Other than those two little incidents, I have had absolutely no issues whatsoever. Any chance you can take a quick video of your slave in action? I've got a feeling that the slave travel of my rod is longer than yours. |

02-02-2014, 04:50 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

You need enough pedal travel to stroke the Tilton master cylinder close to a full 1.1 inches to get full fluid transfer to the slave cylinder. There's a slight amount of play in the clutch pedal linkage that will need to get taken up also. I don't know what the clutch pedal ratio is. Bob recently said the slave cylinder is .81 inch in diameter. So with a 3/4 inch master cylinder (if that is what your car came with) and the slave cylinder being a little larger diameter than the master cylinder, a 1.1 inch master cylinder stroke will only move the slave cylinder about 1 inch. So, pedal travel is important if the clutch needs more fork movement to disengage. With 2 clutch discs, it makes sense that it might need more fork stroke - but they may compensate for that in the diapragm finger design.

Tilton 74 & 75 Series Master Cylinders - Free Shipping on All Orders @ JEGS

I still think you should try pre-loading the clutch through the linkage and see if the wheels are free to turn then.

Last edited by DanEC; 02-02-2014 at 04:52 PM..

|

02-02-2014, 05:00 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Yep, preloading the pressure plate would at least let you know what shape you're in.

I've only had this happen on one other setup, and it was a Superformance. It used the late model Mustang fork and pivoted on the other side, but it was the same situation, not enough travel to engage the clutch.

The owner found out that the clutch pedal had two different pivot points drilled for the master cylinder pushrod, and he just swapped points. Any chance the ERA pedal is like that?

|

02-02-2014, 05:09 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

I can tell you that preloading was absolutely, positively not needed with my Centerforce DF clutch. Yes, that POS Centerforce....  Edit

Edit -- ... along with a Lakewood BH and Spacer in front of the Tremec. Nothing fancy.

Last edited by patrickt; 02-02-2014 at 05:25 PM..

|

02-02-2014, 05:26 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

The owner found out that the clutch pedal had two different pivot points drilled for the master cylinder pushrod, and he just swapped points. Any chance the ERA pedal is like that?

|

Yes, the ERA pedal arm does have two positions for the rod to the master cylinder. The rod should be in the outer hole for max stroke. Good question.

Also, the pedal arm is splined to the pedal shaft also and can be clocked as desired. For maximum effectiveness the arm should be hanging just a little forward to the front of the car so that it rotates back in the 5 o'clock to 7 o'clock range as much as possible. If clocked too far back (7 to 8 o'clock area) then the rod will get less rearward (horizontal) motion (and master cylinder stroke) for movement of the pedal.

Last edited by DanEC; 02-02-2014 at 05:31 PM..

|

02-02-2014, 05:33 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

It is difficult to put together incorrectly. I suppose, though, if Lippy tried really hard to do it wrong he could possibly come up with a way to do just that.

Last edited by patrickt; 10-25-2016 at 11:47 AM..

|

02-02-2014, 05:49 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

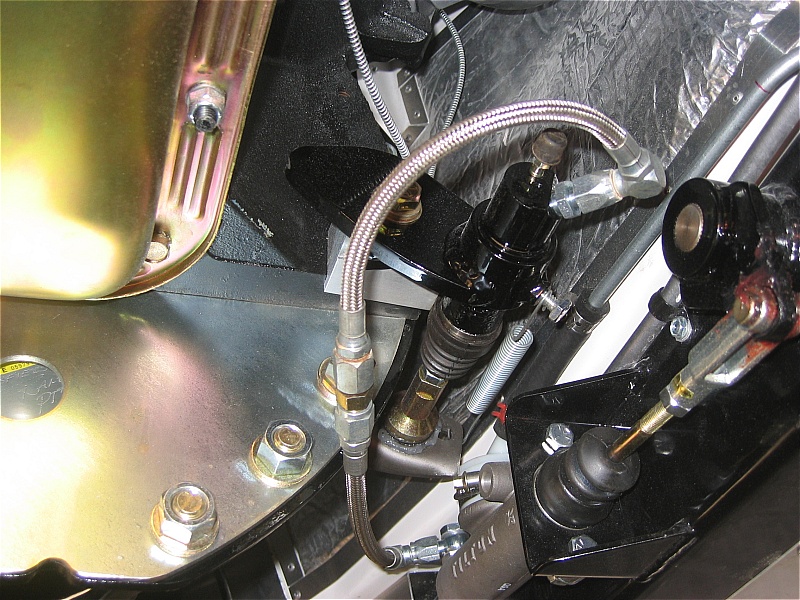

^^^Why a union in the master to slave line?

__________________

Chas.

|

02-02-2014, 06:02 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

^^^Why a union in the master to slave line?

|

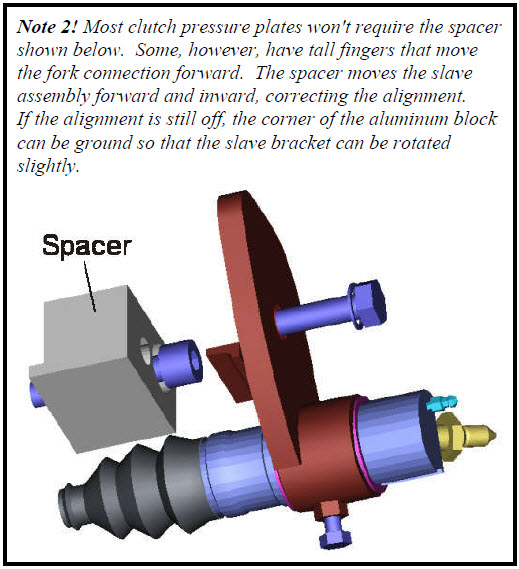

You see that chunk of aluminum that is between the bracket that holds the slave and the block? When that chunk of aluminum is used to move the slave bracket back towards the front of the car, and inwards, then the preferred method is to union the pieces between the slave and master. That chunk of aluminum is actually a rather carefully milled spacer, drilled with the appropriate holes. Some builds need them, some don't. |

02-02-2014, 06:19 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

When that chunk of aluminum is used to move the slave bracket back towards the front of the car, and inwards, then the preferred method is to union the pieces between the slave and master.

|

Don't see why. The length of the line is fixed and the line can be opened at either end. No need to open in the middle.

Even installing a spacer after initial assembly without one, you just cut a new one piece line. You don't cut the now-short original line and install fittings to leak (air in) and a union.

Just looked at mine and in the days before the spacer was thought of, just a simple braid line...

__________________

Chas.

|

02-02-2014, 06:25 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Yes, it would seem that just a plain straight shot would be easier. The spacer is interesting as well. I do not have an appreciation for the subtleties that dictate its use in some combos and not others. And I don't know whether Lippy is using one or not. I can tell him though that mine just bolts right up and bleeds out with no trouble at all. I've had it all apart, both the master and slave just sitting on the garage floor, then I just bolt it back in, a quick bleed, a quick adjustment with a feeler gauge, and *poof* it works like a charm.

Last edited by patrickt; 10-25-2016 at 11:47 AM..

|

02-02-2014, 07:17 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Not sure I understand the 2-piece line either - mine is a single piece line and I use the spacer. Just a parts difference I guess. I didn't get one of those snazzy, built-up, slave cylinder rod nuts either.

The master cylinder rod on my pallet car was installed by ERA and since Lippy's was a roller, I'm sure it was installed on his by ERA also. So, I'm sure his rod must be in the correct hole on the pedal arm.

|

02-02-2014, 07:32 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

In his first post, Lippy writes "Where the slave rod meets the clutch fork, I get a total of about 1/2" - 3/4" movement." If you look at my video, I get two to three times that -- I think he should move the slave closer to the fork, bleed it again, this time with the nose up in the air, and if that still fails, remove the clutch assembly set screw and rotate the clutch pedal way up towards the seat so he could get a test push of an extra long amount and that should at least rule out some sort of goof-ball binding inside the bell housing. Anyway, that's what I would try....

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:37 PM.

Links monetized by VigLink

|