Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

10-11-2014, 01:20 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Lubricating the Smiths Speedometer Cable To Stop Needle Bounce

Lubricating the Smiths Speedometer Cable To Stop Needle Bounce

Recently we've had some threads on the Smiths speedometer and its bouncing needle. Last week, out of the blue, my reverse Smiths speedo starting having some pretty good bounce. Like 120 degrees of bounce, that would come and go, and then went away for a while, came back, but not as bad. It always had some bounce below forty miles an hour or so. Plus, the speedometer has always been off a little, but I really didn't care that much because I almost exclusively use the tachometer to tell me how fast I'm going.

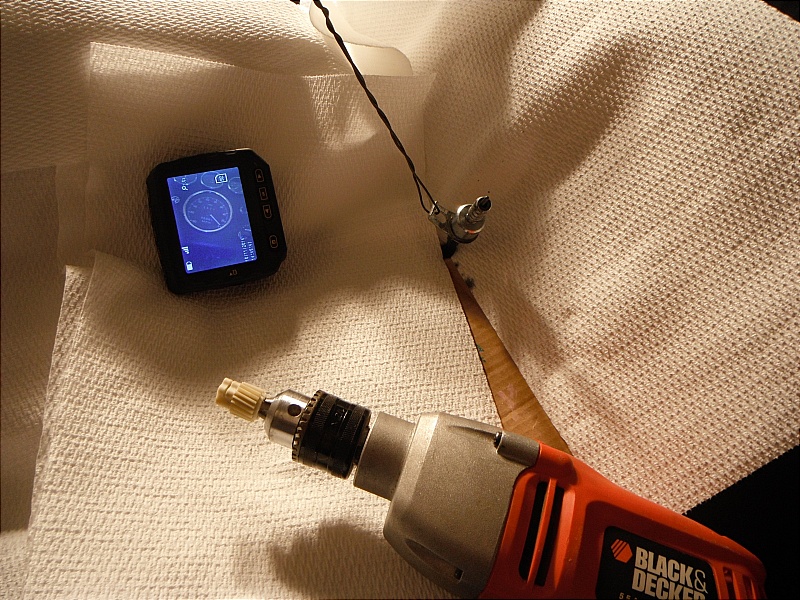

One of the previous threads had mentioned Dri-Slide, so I looked in to it and ordered some - it's pretty cool stuff. I also carefully calculated the driven gear ratio for my tires and rear and ordered a nice Scott Drake 19 tooth driven gear from Summit. Well, when I pulled it apart there was a 19 tooth gear already in there. I then pulled the transmission cable end up through the engine bay, so it was higher than the speedometer, and then put paper towels around it. This Dri-Slide stuff stains everything, permanently, and you need rubber gloves to use it -- if you get it on your fingers, it's next to impossible to wash it off. It comes with a small syringe-like squirter that you slip in to the cable, squirt the liquid in, and then the liquid evaporates off and leaves the dry lubricant. I did that a couple of times, turning the cable by hand after squirting it in so it would work its way down (which is really up) the cable.

You can see in the pics how I did it, then I put the extra driven gear in my reversible drill, put my remote camera on the speedometer, and the display right there in front of me. The fastest my drill will go is about 40 miles an hour, but the needle is almost rock-solid at all speeds up to that, which was never the case before.

This is about a ten minute job, with about 20 minutes of preparation to avoid making a big mess. But it does indeed eliminate the needle bounce.

Last edited by patrickt; 10-25-2016 at 12:05 PM..

|

10-11-2014, 06:57 PM

|

|

CC Member

|

|

|

Join Date: Dec 2012

Cobra Make, Engine:

Posts: 973

|

|

Not Ranked

Not Ranked

Mine started bouncing this week as the temps dropped into the 30s/40s. It only does it when cold and only in first gear.

|

10-11-2014, 07:20 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 66gtk

Mine started bouncing this week as the temps dropped into the 30s/40s. It only does it when cold and only in first gear.

|

OK, if you use the Dri-Slide, treat it as if it were fuming sulfuric acid and try not to get it on anything.  |

10-13-2014, 04:31 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

Well done Patrick. If I ever get a Smith's speedometer (could not think of a Smith's speedo) I will most certainly do this. However my SW gauge seems to work fine and if I changed the speedometer I would have to change all the other SW gauges.

Phil

|

10-14-2014, 02:41 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,502

|

|

Not Ranked

Not Ranked

PLEASE!!! I do not want to see any of you wearing a Smith's speedo while checking your Smith's speedometer for bounce  |

11-10-2014, 02:15 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by GT350Mike

|

I had never heard of Dri-Slide until a recent thread about it. I just ordered a bottle off of Amazon after reading a few positive posts about it on the 'net. For all I know, your chain lube might be much better. |

11-11-2014, 12:12 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Wait A Minute...

Wait A Minute...

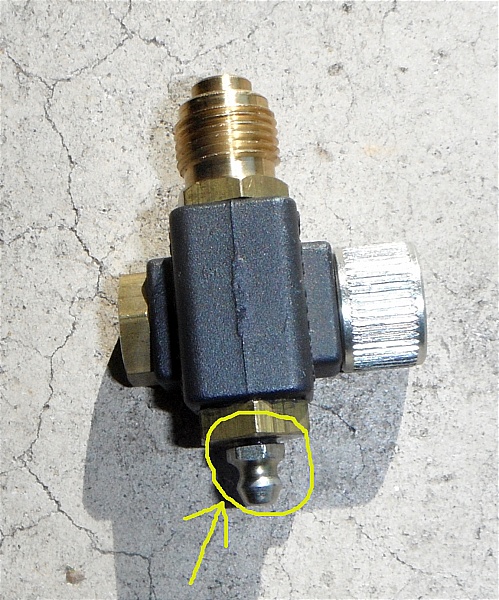

Mike, you do know that the reverser on a Smiths reverse rotation speedometer running a TKO (maybe others) has a Zerk fitting on it?

I'm sure I have written about this in the past, but just in case you didn't know it, here's a pic of mine. A few years ago my speedometer started to misbehave. Now this was not just a needle wobble, this was a "kerchunky" noise coming from the speedometer and the needle bounced from zero to 180. I could reach under the dash while driving and, with my fingers, could feel the rotational bind up in the cable itself. I pulled the cable off the reverser, eased out the inner cable an inch or so from inside the outer cable sheath, and rotated it with my thumb and finger. It rotated fine (being pulled away from the driven gear in the transmission). That told me the problem was either the driven gear, the right angle reverser, or the speedometer itself. I removed the reverser and, by hand, turned the little driven spike that comes out and connects to the speedometer. I could feel it binded a bit and then loosened up as I rotated it with my fingers. I also saw it had a Zerk fitting. I greased it up with pretty good pressure with my grease gun, using the same Schaeffer's grease that I use on my universal joints. That fixed it beautifully. Just like magic. It didn't occur to me until today to mention this to you because, generally, most of us here on this forum know that if you see a Zerk, then you grease the Zerk.  But, you might not have seen the Zerk because it can be pointed over on the side away from you. So, if it was me, when you lubricate the cable, pull your reverser off and give it a good lube. It can't hurt.

Last edited by patrickt; 10-25-2016 at 12:06 PM..

|

11-11-2014, 12:17 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

<double post> sorry.

|

11-11-2014, 11:01 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Cobra Make, Engine: CSX6363

Posts: 180

|

|

Not Ranked

Not Ranked

The symptoms you mentioned were almost exactly like mine (the "kerchunky" is spot on) but I have zero movement in my speedo. Before I installed my adapter I pumped so much grease into it (major brain cramp), the gears were difficult to rotate. After disassembling the adapter to remove the excess grease, it rotated much easier. I think I’ve narrowed it down to either a cable/lube problem (initially, I installed the cable with white lithium grease) and/or the cable itself might be bottoming out inside the adapter which would prevent the gears to turn freely. I ran across a post on CC few nights ago the from someone who had a similar problem (I don’t think he used the word kerchunky but trust me…..its the same) and he was able to fix it by removing roughly 1/32" to 1/16” off the tip of the cable. I’ll let you know how it turns out but in the meantime, let me know if you have any other ideas.

|

11-12-2014, 07:23 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Try this...

Try this...

Quote:

Originally Posted by GT350Mike

problem (I don't think he used the word kerchunky but trust me…..its the same) and he was able to fix it by removing roughly 1/32" to 1/16" off the tip of the cable. I'll let you know how it turns out but in the meantime, let me know if you have any other ideas.

|

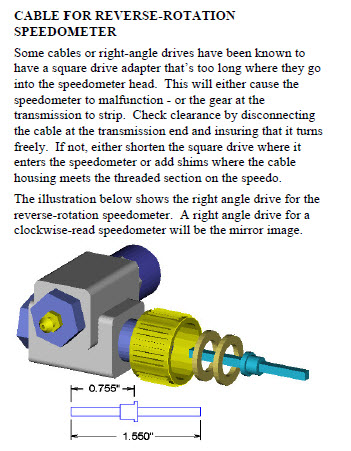

Yes, the cable trim technique is outlined in the ERA Manual. Here I ripped that for you (don't tell Bob P.). The nice thing about a speedometer problem is that there are only a limited number of problem parts, they're all inexpensive (except for the speedometer itself), and you can easily recreate the operating conditions from the comfort of your own garage. The problem has to be either 1) the plastic driven gear on the end of the cable at the transmission; 2) the cable itself, the length of the inner cable, or a tight kink in the cable; 3) the right angle reverser. You could replace all three for less than a hundred bucks. A new speedometer cable is only ten bucks, which is less than the Dri-Slide, but that's how we are....

The almost sure-fire way of diagnosing your problem is to remove the cable from your transmission and inspect the driven gear for any wear. Let's assume it looks perfect. Now remove the cable from the reverser and remove the reverser from the speedometer. With the reverser off the cable, you should be able to spin the cable with your fingers from the driven gear end and it should feel nice, easy and smooth. If it is not, then pull the inner cable out from the outer cable, inspect it, and lube it with Dri-Slide. Next step is to put your driven gear in a reversible drill, spin it at full speed and use the little lock button on your drill to hold it there. Put your hand on the outside of the cable, close to the speedometer end, and feel for vibrations. It should be nice and even. Remember how that feels. Now try turning the reverser, with your fingers, from the little spike that normally goes in to the speedometer. It should be harder to turn, but doable with your fingers, and it should be nice and smooth with no rises, nor falls ,in perceived vibratory tension. Now put the reverser on the end of the cable and fire up your drill again and feel for vibrations. You should not be able to feel a "pulse," but instead it should be nice and smooth. If you feel a pulse, or unusual vibrations, first loosen the cable threads to mimic "shortening the inner cable" and see if that helps. If so, then the inner cable could be bottoming out. If the vibration is still the same, then grease the reverser gently. Turn the gears a bit by hand, grease again. Repeat the test. If you still have vibrations, then grease it hard with your grease gun. You will not be able to turn the little spike with your fingers after a high pressure greasing. Use a nail tip to push the pin in on the Zerk fitting and some grease should pop out from the excess pressure. Now gently turn the spike with pliers. It should loosen up so that you can turn the spike with your fingers. Now retest with the drill. If you still have vibrations/pulses then you should replace the reverser. If it seems good, then put the reverser back on the speedometer and fire up the drill. See if the needle holds steady and the vibrations on the cable are smooth and consistent.

Last edited by patrickt; 10-25-2016 at 12:06 PM..

|

11-12-2014, 08:16 AM

|

|

CC Member

|

|

|

Join Date: Aug 2014

Location: Syracuse,

Ny

Cobra Make, Engine: Superformance #2660, FE-406

Posts: 372

|

|

Not Ranked

Not Ranked

Not for nothing but good motorcycle cable lube works pretty good for this application and you can buy a cheap fitting that allows you to clamp the cable and then feed the lube into it without mess. It will not migrate completely to the low end of the cable...by design.

__________________

The older I get, the faster I was.

|

11-12-2014, 09:06 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

... and Mike, if your current cable/reverser/speedometer combination has ever worked beautifully, then your current problem will not be either the the cable itself, or the little spike between the reverser and the speedometer, bottoming out. But, if you get to the point where the drill is on the floor under the car, spinning the cable as fast as it will go, and you have the reverser attached to the cable, and you're sitting there in the driver's seat with the reverser in your hand, and it feels "buttery smooth," but when you attach the reverser to the speedo you have problems, then suspect the spike between the two or the speedo itself. You can do a "half ass" speedo test by just reaching up behind the dash with the little spike between your thumb and forefinger, and you can spin the speedometer up to almost 20 miles an hour by hand. It should feel light, easy, and smooth when you do that. Or, you could just order a new cable, driven gear, and reverser from Summit and say "screw it all...." |

11-12-2014, 12:11 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Cobra Make, Engine: CSX6363

Posts: 180

|

|

Not Ranked

Not Ranked

Thanks Patrick for the info from the ERA manual.....it helps fill the void if something wasn't covered in my CSX assembly manual.

I've checked the cable to insure it does rotate when the wheels spin forward. I'll elaborate more on this when I get home this evening. |

11-12-2014, 12:14 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by GT350Mike

Thanks .....it helps fill the void if something wasn't covered in my CSX assembly manual.  |

I love it.  |

11-12-2014, 10:06 PM

|

|

CC Member

|

|

|

Join Date: May 2004

Cobra Make, Engine: CSX6363

Posts: 180

|

|

Not Ranked

Not Ranked

When I read your post earlier from my cell, I didn't realize how much info was given in the CAD drawing, especially the specs on the square pin. I think the lube I have from the bike shop will suffice but if it fails, I'll either go with the motorcycle lube of the Dri-Slide.

So far, I've checked the cable rotation with and without the adapter and appears to work fine when I spin the tires. I also tested the adapter on the speedo with the drill and again, it checked out okay. The only thing I haven't done (yet) is disconnect the cable assembly from the transmission to verify if cable feels like its rotating freely.....I save that test for last. After reading through all of the info, I honestly think it's a clearance issue with the cable end or the square pin. Hopefully I'll be able to put scratch this off my to-do list Saturday. Thanks everyone for the info!

|

11-13-2014, 02:58 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2007

Location: Mesa,

AZ

Cobra Make, Engine: Contemporary Classic, 428 FE CCX 3069

Posts: 7,506

|

|

Not Ranked

Not Ranked

NAyone ever think about using Remington Gun Lube? It's a dry lube that does not contain any graphite.. aerosol can with directional tube sprayer.. sounds like it should work to me.

__________________

Dan in Arizona

Dan in Arizona

CCX3209

"It's a great car and I love it, but it doesn't do 'SLOW' very well."

|

11-13-2014, 04:06 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Danr55

NAyone ever think about using Remington Gun Lube? It's a dry lube that does not contain any graphite.. aerosol can with directional tube sprayer.. sounds like it should work to me.

|

I think the outer casing starts to go after a few years. I kind of think one lube is about as good as another. Did you grease your zerk well? |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:45 PM.

Links monetized by VigLink

|