Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

04-07-2015, 05:26 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

427 shifter location

427 shifter location

Got a question that I've often wondered about but never come up with an explanation for it....

289 Cobras have their shifters positioned on the T-10 so that the gearshift is correctly located and requires a normal 'straight' shift lever.

427 Cobras have their Toploader shifters located further aft, requiring a reversed Mustang shift lever to position the shift knob in a comfortable spot for the lucky user.

Why is the 427 shifter located in this position?

Cheers,

Glen

|

04-07-2015, 06:03 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Phoenix,

AZ

Cobra Make, Engine: FFR: 302 w/aluminum heads, Edlebrock injection. Street car trim, no scoop, side pipes or rollbar.

Posts: 1,869

|

|

Not Ranked

Not Ranked

Because they are different transmissions and use entirely different linkages and shifters.

__________________

"Cobra-Cobra-bo-bobra, banana-fanna-fo-fobra, fe-fi-mo-mobra...Cobra!"

|

04-07-2015, 06:21 PM

|

|

Senile Club Cobra Member

|

|

|

Join Date: Feb 2001

Location: Buffalo, NY USA,

NY

Cobra Make, Engine: Superformance

Posts: 4,536

|

|

Not Ranked

Not Ranked

The 427 used a Galaxie "top loader" and the shifter was located rearward of where the T10 unit was thus the "reversed" shifter.

__________________

"I'm high all right, but on the real thing....powerful gasoline and a clean windshield..."

rick@autoventureusa.net

|

04-07-2015, 08:30 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Yes I do understand that the two transmissions are entirely different. One is a Borg Warner T-10 and the other is a Toploader.

Expanding my question a little then....why did Shelby position the shifter mechanism where he did (longitudinally) when he could have positioned it further forward on the side of the Toploader and had a non-cranked shift lever?

There are brackets available for Toploaders that enable the shifter mech. to be placed virtually wherever you want fore-and-aft, so did Shelby (or Rem?) just say "b*gger it, nobody else does it this way, so we will"? ....or "wouldn't 1-2 and 3-4 shifts be nice if the action was up and down rather than fore-and-aft"?

I'm just thinking that there must be some logic there that hasn't hit me yet.

Cheers,

Glen

|

04-07-2015, 09:18 PM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,908

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xb-60

There are brackets available for Toploaders that enable the shifter mech. to be placed virtually wherever you want fore-and-aft, so did Shelby (or Rem?) just say "b*gger it, nobody else does it this way, so we will"? ....or "wouldn't 1-2 and 3-4 shifts be nice if the action was up and down rather than fore-and-aft"?

I'm just thinking that there must be some logic there that hasn't hit me yet.

Cheers,

Glen

|

While there may be many choices of brackets (and locations) available today, I could be wrong, but I suspect the choices available to Shelby at the time were probably far fewer - forcing him to work with what he had.

__________________

Brian

|

04-08-2015, 04:49 AM

|

|

Senile Club Cobra Member

|

|

|

Join Date: Feb 2001

Location: Buffalo, NY USA,

NY

Cobra Make, Engine: Superformance

Posts: 4,536

|

|

Not Ranked

Not Ranked

At that time the trans to handle the power was the Galaxie version with a long tailstock and the shifter rearward (remember this came out of a full size car and the back of the engine was close to three feet away from the shifter hole in the tunnel) so the reversal was required. Had this been 1970 there would have been Mustang and Fairlane applications with mid mounted locations for the shifter and a greater choice of Ford/Hurst shifters and rods.

__________________

"I'm high all right, but on the real thing....powerful gasoline and a clean windshield..."

rick@autoventureusa.net

|

04-08-2015, 10:50 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Windham,,

Me

Cobra Make, Engine:

Posts: 1,590

|

|

Not Ranked

Not Ranked

Actually once you get used to shifter it is not a big deal at all. Personally like the way it is setup, power shifting is not a problem at all. The one thing that was awkward at first was the pedals located to the left, now it feels natural.

|

04-08-2015, 11:18 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,521

|

|

Not Ranked

Not Ranked

Not sure what the Ford shifter unit bracket looks like - may not have been a ready made source to move it forward on the transmission. I suspect (maybe someone can correct me) that 427 engine transmission assemblies came from Ford with a shifter on them. I guess it was simpler to reverse the handle than cobble up a new mount plate, modify the rods, etc.

|

04-08-2015, 12:01 PM

|

|

Club Cobra Member

|

|

|

Join Date: Mar 2002

Location: arroyo grande, ca,

ca

Cobra Make, Engine: NAF 427

Posts: 1,774

|

|

Not Ranked

Not Ranked

I think Dan is right from what I have read. It was also cheaper to simply reverse the lever than add an aftermarket kit at additional cost.

Shelby was a penny pincher.

Cheers

Greg

|

04-08-2015, 04:51 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by my427cobra

I think Dan is right from what I have read. It was also cheaper to simply reverse the lever than add an aftermarket kit at additional cost.

Shelby was a penny pincher.

Cheers

Greg

|

I'm sure you guys are all correct and it was the easiest thing at the time to just reverse the shift lever, and job done.....but it has always seemed an anomaly from Shelby practice as this is the guy that took a 10 year old design with a small 6 cylinder engine, and first stuffed in a 260, and then a 427....and then a 427 with two massive Paxtons!

If a bracket wasn't currently available to move the shifter and lever forward by 3", then it would have taken Phil Remington two minutes to sketch up a bracket, and an hour for one of the mechanics to make it up and shorten the rods.

OK, I'm over-thinking it

Cheers,

Glen |

04-08-2015, 05:50 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Phoenix,

AZ

Cobra Make, Engine: FFR: 302 w/aluminum heads, Edlebrock injection. Street car trim, no scoop, side pipes or rollbar.

Posts: 1,869

|

|

Not Ranked

Not Ranked

then it would have taken Phil Remington two minutes to sketch up a bracket, and an hour for one of the mechanics to make it up and shorten the rods.

And then repeat that last part...for every car made.

OK, I'm over-thinking it

Yep. They flipped the shifter around, it worked. No need to re-invent something, just cut the hole in the tunnel further back.

__________________

"Cobra-Cobra-bo-bobra, banana-fanna-fo-fobra, fe-fi-mo-mobra...Cobra!"

|

04-08-2015, 09:03 PM

|

|

CC Member

|

|

|

Join Date: Jun 2010

Cobra Make, Engine: Viking Blue "64" 289 FIA comp car by Superformance #0002, Keith Craft - 331 (460HP), Jim Inglese - 48IDA Weber carbs, BW T10 4spd.

Posts: 430

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xb-60

If a bracket wasn't currently available to move the shifter and lever forward by 3", then it would have taken Phil Remington two minutes to sketch up a bracket, and an hour for one of the mechanics to make it up and shorten the rods.

OK, I'm over-thinking it

Cheers,

Glen |

Glen,

Perhaps you're over-thinking it as well as underestimating it  ... because there's no "bracket" involved. The tail-housing design (casting) is what sets the shifter location. Moving the shifter mechanism (and have it fit and operate correctly) with a custom bracket is not so easy, especially on these old external linkage units. Hence all the tail-housing variations Ford produced.

As a side note, if you're building an accurate replica of a 289, you'll need the Galaxie configuration - T10 or Toploader, either will work as the shifter location is the same.

Hope this helps.

Last edited by LightNFast; 04-08-2015 at 09:21 PM..

|

04-08-2015, 09:16 PM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

A lot of Shelby's work on the cars was quick and sloppy, with a "get the engines in and sell them" execution. SA was interested in racing, not selling street cars. The tailshaft housing used on the Cobra 427 was drilled/tapped in the rear most shifter position as supplied from Ford. It was easiest to just turn the handle around and leave the shifter attached to the housing.

Larry

__________________

Alba gu brąth

|

04-08-2015, 10:41 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by LightNFast

Glen,

Perhaps you're over-thinking it as well as underestimating it  ... because there's no "bracket" involved. The tail-housing design (casting) is what sets the shifter location. Moving the shifter mechanism (and have it fit and operate correctly) with a custom bracket is not so easy, especially on these old external linkage units. Hence all the tail-housing variations Ford produced.

As a side note, if you're building an accurate replica of a 289, you'll need the Galaxie configuration - T10 or Toploader, either will work as the shifter location is the same.

Hope this helps. |

Hi Kurt.

My Toploader is a C8AR-7006 housing (so '68 vintage) with a D0ZR-7A040-A tailhousing.

Deciphering the tailshaft casting ID tells me that it's a 14" 28 spline tailhousing, probably originally specc'd for small block fitment in a Cyclone/Fairlane/Torino or Mustang/Cougar/Torino 390

Not sure a Galaxie config. is what I would have wanted as Galaxie tailhousings are 17" and 31 spline so that's too long (IMO) for a very short tailshaft.

My Toploader's most recent duty was in a 351 Falcon (Australian), in which application it would have needed the shifter mechanism further aft. It achieved that with a bracket that moves it back three or four inches.

My David Kee agent, who's doing the rebuild, tells me that brackets were commonly used to position the shifter in the correct place. It's just a very simple bracket.

Digressing - that beautiful 289FIA is keeping you entertained?

Cheers,

Glen

|

04-08-2015, 10:46 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by LMH

A lot of Shelby's work on the cars was quick and sloppy, with a "get the engines in and sell them" execution. SA was interested in racing, not selling street cars. The tailshaft housing used on the Cobra 427 was drilled/tapped in the rear most shifter position as supplied from Ford. It was easiest to just turn the handle around and leave the shifter attached to the housing.

Larry

|

Larry - I hadn't thought about the necessity of drilling and tapping blanked bosses on finished gearboxes to move the shifter to the 'correct' location. That's probably the logic I was missing.

Cheers,

Glen |

04-09-2015, 04:21 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Windham,,

Me

Cobra Make, Engine:

Posts: 1,590

|

|

Not Ranked

Not Ranked

When building our car with big block and toploader it was obvious why the shifter was in it's location. It would have been impossible to move it forward the shift rods were already quite short. Moving the shifter forward would have made it next to impossible to make it work not to mention it would then not look like the originals.

When converting over to a Tremec it was a no brainer where the shifter was to reside.

|

04-09-2015, 06:10 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,521

|

|

Not Ranked

Not Ranked

[quote=LightNFast;1344614]Glen,

Perhaps you're over-thinking it as well as underestimating it  ... because there's no "bracket" involved. The tail-housing design (casting) is what sets the shifter location.

QUOTE]

That's the part I wasn't sure about with the factory Ford shifter - did it even use a mounting bracket or did it bolt directly to the tail housing? |

04-09-2015, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

That's the part I wasn't sure about with the factory Ford shifter - did it even use a mounting bracket or did it bolt directly to the tail housing?

|

Dan, as far as I know, the Ford Toploader shifter fitted to the Toploader gearbox in a 427 Cobra bolted directly onto the gearbox tailhousing, the only mod being to reverse the shift handle.

My logic had me thinking why didn't Shelby just fit a bracket ....etc ....because my Toploader has a bracket to mount the Hurst shifter mechanism to the tailhousing (for previous Falcon-fitment duties). Here's a picture of my Toploader pre-rebuild...

The shifter mechanism, post-rebuild, will be relocated further forward so that it's in the correct position for a 289.

Cheers,

Glen |

04-09-2015, 07:39 PM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

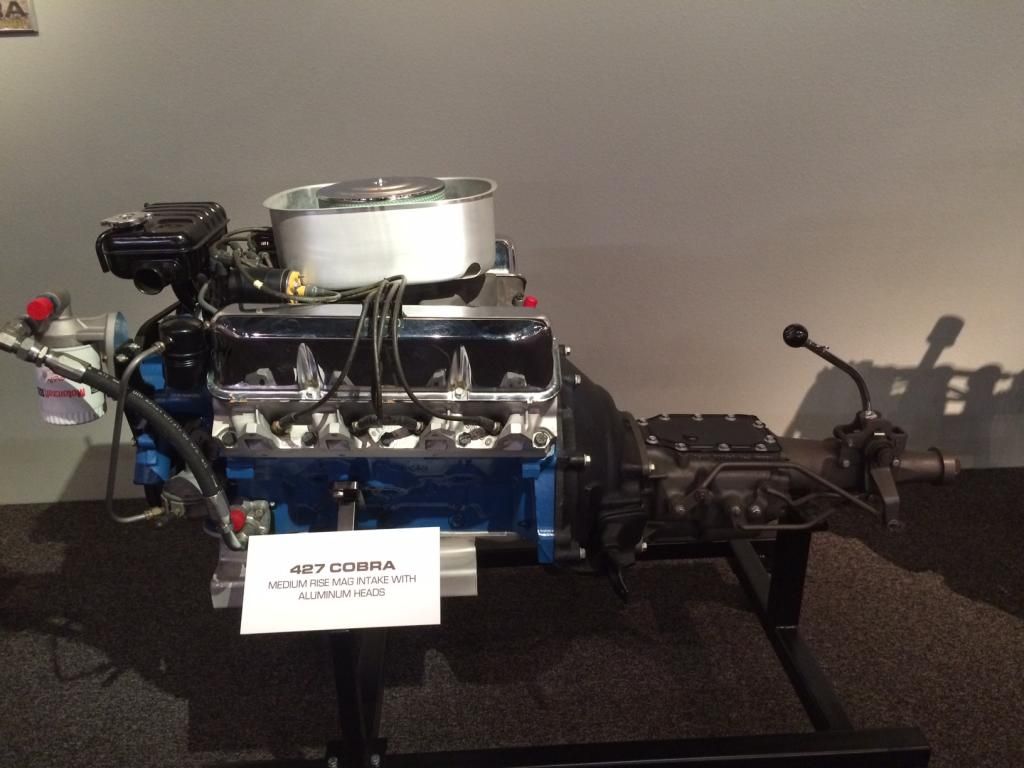

Photo from The Cobra Experience museum in Martinez, CA.

Larry

__________________

Alba gu brąth

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:46 AM.

Links monetized by VigLink

|