Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

5Likes 5Likes

09-23-2020, 12:57 PM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Hideaway, Texas,

TX

Cobra Make, Engine: Backdraft #318, 418 CI, 532 RWHP, Mass Flow Injected, TKO600-Road Race, BMW M3 Suspension, Race Springs (Wouldn't do it again, rough on the street).

Posts: 240

|

|

Not Ranked

Not Ranked

TKO 600 Shifting-Had Enough Finally

TKO 600 Shifting-Had Enough Finally

After 10 years of really poor shifting on a TKO 600 behind a SBF (2nd to 3rd hangs in the gate), I have had it.

So, after reading all the issues and fixes over the years, now I'm finally interested. About time I guess. My particular unit is absolutely terrible between 2nd and 3rd at speed (it's OK enough cruising). I have aligned the bell housing, checked runout, input shaft length and all the rest. Had the thing out of the car numerous times along the years and it's all OK on the outside. Years ago I installed a Tri-Ax shifter, which did improve almost everything else....except the second to third shift. So, what remains the best solution? Liberty Gears or........ And before it starts, yes I do have considerable experience with a lot of different trans types and shifting, probably too much and mostly on the road race tracks around the world as a professional. In fact, my unit could not be raced even at an amateur level taking it easy on a track day, just not possible to count on that one shift at all. Really appreciate any input, especially if you have had one corrected and by whom. Thanks!

__________________

Wayne Rogers in Hideaway, Texas

Last edited by wrogers55; 09-23-2020 at 01:07 PM..

|

09-23-2020, 01:42 PM

|

|

CC Member

|

|

|

Join Date: Sep 2003

Location: Colgate,

WI

Cobra Make, Engine: FFR 4071, SHP 408 Carb dry sump, G-Force T-5, 4 into 4 headers, 3-link 8.8 with 3.55 gears in the rear

Posts: 56

|

|

Not Ranked

Not Ranked

Many others know way more about trannys than I do. However, I've had my fare share of tranny issues and have learned a little along the way. I had issues with the shift to third with a T-5 and G-Force gears. I wound up having to replace 3rd gear, synchronizers, and the counter shaft. To me it sounds like you could have a synchronizer going bad. I hope to learn more as I follow this thread.

Robert

|

09-23-2020, 02:35 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Wayne,

I lived what you are going through. This is the fix I found. It is a two step fix. Step #1 is ship the unit to Liberty and have them do their magic internally. If you are comfortable working Iside a manual transmission you can do the job yourself on a Saturday morning and save shipping. Even if you are comfortable working inside a manual transmission go to the Tremec website and get Tremec's Service Manual for the TKO 600. It will make the job easier.

What you need from Liberty is the following:

- Bronze Shift Fork Pads

- Surface Enhancement Processed Hubs & Sliders

- Internal Shift Linkage Upgrade

- Carbon Fiber Blocking Rings—2nd, 3rd & 4th Gear

Additionally I highly recommend you switch to a special Pro 5.0 midshifter for the transmission. It will produce a straight vertical shifter located at the front edge of the driver's seat positioned very much like a 289 car, which has excellent sifting ergonomics.

Shifting ergonomics notwithstanding, the midshift position removes a troublesome internal shift rail from the mid shift location to the rear shift location that was the source of considerable shifting slop and shift problems. Liberty's internal shift linkage upgrade will change the interlock timing on the second to third gear change, which is absolutely essential for a good 2 to 3 gear change.

The Pro 5.0 shifter you need is not well advertised and not available directly from Pro 5.0 because their dealers need to make modifications to it to work in the TKO midshift location.

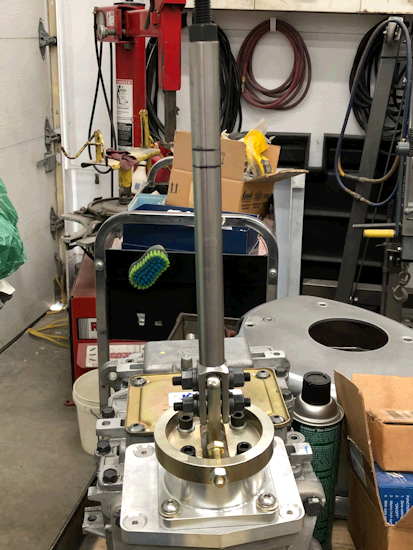

This is a picture of the shifter installed on my TKO.

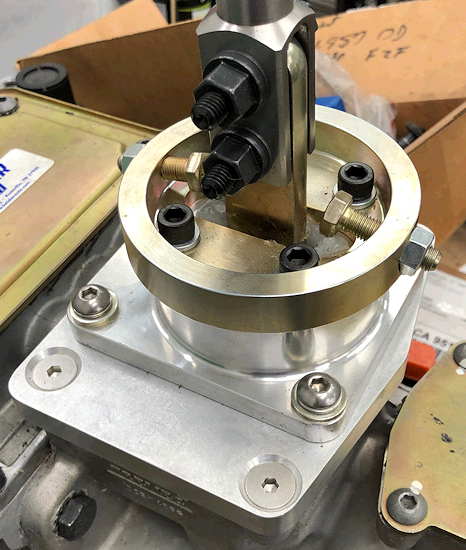

The two sharpie lines are for a shift ball height of either 6 or 6.5 inches from the top bolt at the bottom of the shifter to the top of the shift ball. Make yours 6.5 inches or taller. You can easily shorten it to fit your taste. If you go too short, lengenthing it means starting over.

The Pro 5.0 shifter assembly is relatively short so it makes for a nice fit,

I chose to build my own shifter arm that bolts to the Pro 5.0 gizmo. I used a 1.25 inch bar of 17-4 ph stainless and machined the bottom to look pretty but also put the shifting lever in double shear on the Pro 5.0 shift stub.

Another view of the bottom,

The shifter is available from Forte or Hanlon and is easily installed. If you can change plugs you can install this shifter!

The shifter is not easy to find on Forte's site. This is the url, click here => https://fortesparts.com/product/mid-shiftier-tko-500-600/

Here is the Hanlon Pro 5.0 midshift conversion url, click here => http://hanlonmotorsports.com/hms-mid-shift-kit

The little black gizmo you see in the picture on Forte's site significantly improves the transition from second gear to third gear. Be sure to use it.

Once you have made the modifications you will curse yourself for not doing it sooner.

This is a pic of the custom Kirkham manufactured midshifter they put in the billet Cobra for Larry Ellison. Click here => Interior and go down to the fourth photo.

That should be enough to keep you busy for a while. Definitely do the Liberty mods and I highly recommend the midshift conversion. It is way more natural to drive and much better shifting because of linkage reductions in the internal rail system.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 08-29-2021 at 10:44 AM..

Reason: Fixed Broken Links

|

09-24-2020, 10:23 AM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Hideaway, Texas,

TX

Cobra Make, Engine: Backdraft #318, 418 CI, 532 RWHP, Mass Flow Injected, TKO600-Road Race, BMW M3 Suspension, Race Springs (Wouldn't do it again, rough on the street).

Posts: 240

|

|

Not Ranked

Not Ranked

Ed, thanks for the details. I know that took some time and it is much appreciated. I'm going to give Liberty a call this week and hope they are working during this mess. Everything you said makes sense and I really like the fact you have been through it to the end. I will say that double shear shift lever raised an eyebrow! I think you would break your arm before you broke that off. Good work actually and one of those "I never have to think about this again" designs. BTW, I lived in San Martin for 34 years with my office at Laguna Seca, but with a Gilroy address. Too bad we never crossed paths being so close. Thanks again for the great road map. Wayne

__________________

Wayne Rogers in Hideaway, Texas

|

09-24-2020, 10:40 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

More than happy to be able to help, Wayne.

It would have been nice to meet before you left for Texas. As uou already know Texas is a popular destination for Californians who are trying to escape the madness that is modern day CA. Sad. It used to be a much nicer place to live. Although the climate is obviously still good it is just everything else — what a shame ...

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 09-24-2020 at 10:50 AM..

Reason: Spelling & Grammar

|

09-24-2020, 01:10 PM

|

|

CC Member

|

|

|

Join Date: Jan 2017

Location: Glendale,

AZ

Cobra Make, Engine: FFR MkIV 427

Posts: 636

|

|

Not Ranked

Not Ranked

[quote=wrogers55;1483071]After 10 years of really poor shifting on a TKO 600 behind a SBF (2nd to 3rd hangs in the gate), I have had it.

I had the same/similar problem for 4 years, power shift into third would hang and grind, with a brand new TKO600 with Tremec's mid-shifter. Gordon Levy sold me a different shifter, I don't know which one, but it shifts great now. According to Gordon, some shifters don't have as much leverage as others. Levy Racing Maricopa, AZ.

Now, if I could get the damn thing to stop leaking.

|

09-24-2020, 07:24 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Midlothian,

TX

Cobra Make, Engine: Hurricane 427 Cobra #HM2008, Craft Performance 427w 600hp/600tq, TKO-600 close ratio, original Smiths gauges, lucas switches

Posts: 1,022

|

|

Not Ranked

Not Ranked

Allow me to jump into this thread, please:

First, Wayne: Welcome to Texas! I live in the DFW area, work from home, but a few days a month I drive through Hideaway on my way to Longview for work. We have a very active group in the DFW metroplex, and I know of one of our members that lives in Longview as well. We have the state-wide Texas Cobra Meet each spring in the hill country, base camp in San Marcos. This year due to covid it was postponed to October 7-11 -now less than two weeks! The latest attendance numbers are :

177 Drivers and Guests

99 Cars registered (so far)

118 Banquet Tickets sold

10 Different states represented

Texas Cobra Club Fall Meet for more info - should come check it out!

Ed: Thanks very much for the detailed post with pictures, links, and info. Invaluable information! I have the same problem as Wayne, and more - here is my story:

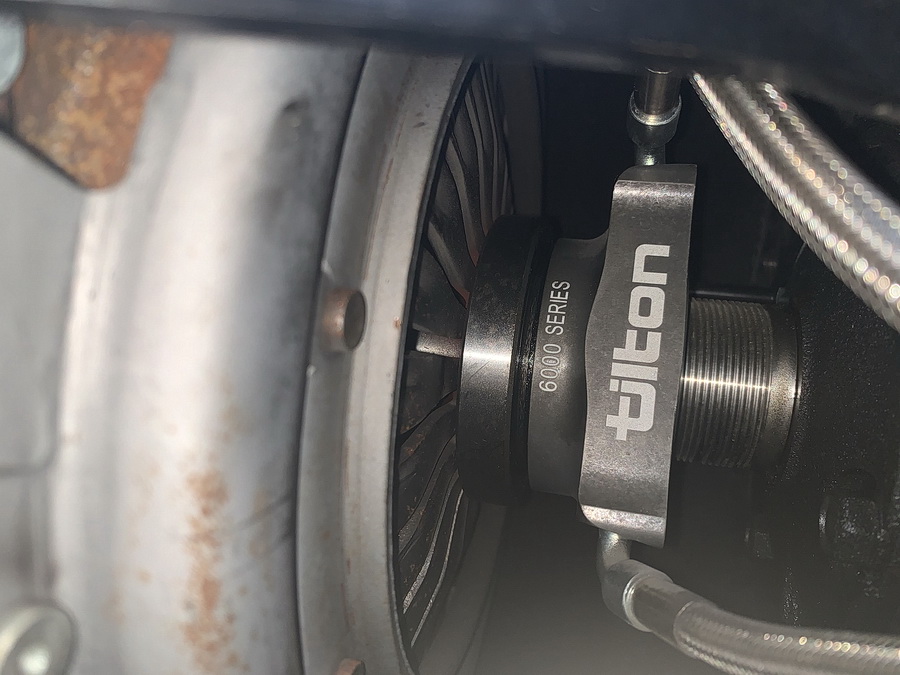

My setup 351/427w, 600hp/600tq on the engine dyno, built by Craft Performance Engines. TKO-600 w/.82 OD, Ram Clutch, Tilton 60-6102 internal hydraulic throw out bearing. Now with 5500 miles on the odometer.

I've been having a hell of a time with my clutch/trans lately. Its started after driving a while and coming to a stop, I go into neutral. Then when the light turns green it will not go back into first gear, or barely second. like i'm not pressing the pedal at all. I pump and pump until it finally goes in. I'm afraid i'm going to bend some forks or some such... and then later sometimes it will slide right into gear, no problem!

When this first started happening, I called the Tremec rep and regional distributor for Tremec, where I bought it. He said it sounded like the clutch fluid was boiling (btw he uses and recommends Tilton internal TOBs on all their race cars). But I said I have heat shields and i dont think thats it. He said if you kill the engine and then put it in gear does it glide in? if so then the clutch isn't disengaging. I haven't tried that yet, because I'm always in traffic. Besides, I can't start the engine while the transmission is in gear - I'm using the neutral safety switch.

Then it happened again last weekend on cold start right out of the garage ... so i can't be heat related.

This weekend i'll visually inspect the TOB through the bell housing window and see if i can see any leakage, and bleed out the clutch system again. BTW, I use Wilwood Hi-Temp 570 Degree Racing Brake Fluid 290-0632 in brakes and clutch.

The next question is: I have experienced the same as Wayne shifting from 2nd to 3rd under hard acceleration - I thought I was just missing 3rd, and had to stab it again. Ed, your recommendation in part is to move the shifter forward to the middle position. I'm not sure I would want to do that, having to cut the trans tunnel and carpet for a new location - and I also want to keep the original looking mustang reversed stick shift. Would making the internal only upgrades help with this problem, and possibly the aforementioned problem as well?

__________________

Bob Worley

Hurricane HM-2008 build is done!! (for now....)

Craft Perfomance 427W / 600hp / 600tq - TKO600

I love it and I need it I bleed it ~ Yeah it's a wild hurricane ~ Alright, hold tight, I'm a highway star!!

|

09-24-2020, 07:37 PM

|

|

CC Member

|

|

|

Join Date: Nov 2007

Location: Clayton,

IN

Cobra Make, Engine: ERA 838

Posts: 1,126

|

|

Not Ranked

Not Ranked

My last car had the 2 to 3 shift issue as described above.

I am building a new ERA and will have the TKO fixed before it goes in. I wish there was a better transmission option.

John

|

09-24-2020, 07:50 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Manchester,

MO

Cobra Make, Engine: Hurricane - FE

Posts: 627

|

|

Not Ranked

Not Ranked

Bobby & Wayne

Make sure you're getting proper air gap on the clutch disc with the pedal depressed, and that your pedal is moving the master cylinder puck enough distance. It is a fine balancing act and littlee amounts add up.

And the Tremec's don't like a disc that is dragging when you shift

Paul

|

09-24-2020, 07:53 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Midlothian,

TX

Cobra Make, Engine: Hurricane 427 Cobra #HM2008, Craft Performance 427w 600hp/600tq, TKO-600 close ratio, original Smiths gauges, lucas switches

Posts: 1,022

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PaulProe

Bobby & Wayne

Make sure you're getting proper air gap on the clutch disc with the pedal depressed, and that your pedal is moving the master cylinder puck enough distance. It is a fine balancing act and littlee amounts add up.

And the Tremec's don't like a disc that is dragging when you shift

Paul

|

Paul, I think my clutch master cylinder is .70 bore. its Wilwood mini MC. I'll have to check when I get home. My clutch pedal is extra long, like the original cobras - i built the false floor and lengthened the pedal 3.5" more.

__________________

Bob Worley

Hurricane HM-2008 build is done!! (for now....)

Craft Perfomance 427W / 600hp / 600tq - TKO600

I love it and I need it I bleed it ~ Yeah it's a wild hurricane ~ Alright, hold tight, I'm a highway star!!

Last edited by bwcobra15; 09-24-2020 at 08:00 PM..

|

09-24-2020, 08:18 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Manchester,

MO

Cobra Make, Engine: Hurricane - FE

Posts: 627

|

|

Not Ranked

Not Ranked

Bobby,

Number of things:

1) are you getting full stroke with the longer pedal. I suspect it is bottoming out before you move the mastercylinder puck to its limit

2) What size is your slave cylinder? Using a .70 diameter mastercylinder for a clutch is extremely rare. You probably aren't pushing enough fluid

3) Most pressure plates require 1/2" movement at the throwout bearing. With the Ford clutch lever, that translates to about 7/8"-1" at the end of the lever, where the slave cylinder attaches - meaning the slave cylinder has to move that same distance. If your slave is any bigger than the master cylinder diameter, you will have issues.

The Wilwood slave is 7/8" bore. To move it 1", you need .6 cubic inches of fluid. The Wilwood masters used on Hurricanes have 1.25" of stroke. To get that much fluid, you need the 13/16" bore and it needs to move full stroke. It would be better with a 7/8" bore but Wilwood doesn't make one in that style.

With less than full movement, you reach a point the clutch releases but doesn't let the disc free wheel. Two issues - the transmission won't shift right and the clutch will wear quicker.

Remember in school - why do I need this math, I'll never use it  |

09-24-2020, 08:43 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Midlothian,

TX

Cobra Make, Engine: Hurricane 427 Cobra #HM2008, Craft Performance 427w 600hp/600tq, TKO-600 close ratio, original Smiths gauges, lucas switches

Posts: 1,022

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PaulProe

Bobby,

Number of things:

1) are you getting full stroke with the longer pedal. I suspect it is bottoming out before you move the mastercylinder puck to its limit

2) What size is your slave cylinder? Using a .70 diameter mastercylinder for a clutch is extremely rare. You probably aren't pushing enough fluid

3) Most pressure plates require 1/2" movement at the throwout bearing. With the Ford clutch lever, that translates to about 7/8"-1" at the end of the lever, where the slave cylinder attaches - meaning the slave cylinder has to move that same distance. If your slave is any bigger than the master cylinder diameter, you will have issues.

The Wilwood slave is 7/8" bore. To move it 1", you need .6 cubic inches of fluid. The Wilwood masters used on Hurricanes have 1.25" of stroke. To get that much fluid, you need the 13/16" bore and it needs to move full stroke. It would be better with a 7/8" bore but Wilwood doesn't make one in that style.

With less than full movement, you reach a point the clutch releases but doesn't let the disc free wheel. Two issues - the transmission won't shift right and the clutch will wear quicker.

Remember in school - why do I need this math, I'll never use it  |

Very good info, Paul -- reminder: I have the Tilton hydraulic TOB, so no slave cylinder or clutch lever arm  I"ll confirm which M/C I have tomorrow night when i get back home.

__________________

Bob Worley

Hurricane HM-2008 build is done!! (for now....)

Craft Perfomance 427W / 600hp / 600tq - TKO600

I love it and I need it I bleed it ~ Yeah it's a wild hurricane ~ Alright, hold tight, I'm a highway star!!

|

09-24-2020, 09:38 PM

|

|

CC Member

|

|

|

Join Date: Apr 2010

Location: melbourne,

vic

Cobra Make, Engine: Robnell Blown LS1

Posts: 296

|

|

Not Ranked

Not Ranked

I also had a similar problem with hard shifting with my TKO600 and it was a bugger to get into 1st whist stationary.

Long story but we had fitted a HTOB which bolted to the input shaft housing on the trans.

The bolts were slightly too long and were pushing against the main shaft shims which was effectively over-shimming the main shaft.

Eventually worked this out and rectified... Now shifts beautifully.

Maybe worth checking the main shaft has been shimmed correctly.

Cheers

|

09-24-2020, 09:59 PM

|

|

CC Member

|

|

|

Join Date: Apr 2010

Location: melbourne,

vic

Cobra Make, Engine: Robnell Blown LS1

Posts: 296

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bwcobra15

Very good info, Paul -- reminder: I have the Tilton hydraulic TOB, so no slave cylinder or clutch lever arm  I"ll confirm which M/C I have tomorrow night when i get back home. |

The easy way to check disengagement is to jack the rear of the car, whilst in gear get another person to try turning the rear wheel whilst you slowly engage the clutch pedal.

When the wheel starts to free up then measure the distance between the pedal at that point and the pedal stop or when it bottoms on the firewall or carpet etc.

Should be around 1/2” from memory. |

09-25-2020, 02:10 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bwcobra15

I've been having a hell of a time with my clutch/trans lately. Its started after driving a while and coming to a stop, I go into neutral. Then when the light turns green it will not go back into first gear, or barely second. like i'm not pressing the pedal at all. I pump and pump until it finally goes in. I'm afraid i'm going to bend some forks or some such... and then later sometimes it will slide right into gear, no problem!

When this first started happening, I called the Tremec rep and regional distributor for Tremec, where I bought it. He said it sounded like the clutch fluid was boiling (btw he uses and recommends Tilton internal TOBs on all their race cars). But I said I have heat shields and i dont think thats it. He said if you kill the engine and then put it in gear does it glide in? if so then the clutch isn't disengaging. I haven't tried that yet, because I'm always in traffic. Besides, I can't start the engine while the transmission is in gear - I'm using the neutral safety switch.

Then it happened again last weekend on cold start right out of the garage ... so i can't be heat related.

|

There is a fair amount of heat inside the bellhousing. In fact the first generation McLeod HTOB's used braided stainless lines with banjo fittings to move the brake fluid in and out of the HTOB. The banjo fittings used rubber o-rings to seal at their pivot joint. The clutch heat inside the can would destroy those o-rings after a while and the HTOB would fail requiring a lot of work to replace / repair it.

The newer McLeod's and the Tilton HTOB you are using do not use banjo fittings so they should not experiencee that particular failure. Detroit successfully uses HTOB's in increasingly more and more vehicles. They usually use steel tube instead of braided stainless with banjo fittings — few if any failures. Significantly the o-rings internal to the HTOB which seal the moving sleeve, that pushes the actual TOB against the clutch fingers, do not appear to experience heat related failures.

The shift lever locking effect is a result of the erector set like linkage Tremec uses for the shift rod going between the mid shift location and the rear shifter location. It is simply more moving parts that need to be carefully managed — that sometimes are and sometimes are not. When they are not it is possible to lock up the internal rails. Removing a couple of covers and using a large screwdriver it is possible to free up the shift linkage and reassemble all the pieces you took off to fix the whoopse.

Quote:

Originally Posted by bwcobra15

This weekend i'll visually inspect the TOB through the bell housing window and see if i can see any leakage, and bleed out the clutch system again. BTW, I use Wilwood Hi-Temp 570 Degree Racing Brake Fluid 290-0632 in brakes and clutch.

|

The presence of the problem in cold weather and also your use of Willwoood HiTemo racing brake fluid pretty much precludes boiling the fluid. Not that you can't, but in a non race environment I think you would have to work pretty hard at boiling the fluid — especially the Willwood Hi-Temp 570 Degree Racing Brake Fluid.

The difficulty in shifting vs the linkage locking up are two different problems. The shifting problem is typically a clutch that is just shy of completely releasing. Kyleb's approach to finding the clutch disengagement point in his post #14 is a very good and easy to do fix. Unless your bell housing is off center from the crank rear flange that should fix the hard to shift problem.

Quote:

Originally Posted by bwcobra15

The next question is: I have experienced the same as Wayne shifting from 2nd to 3rd under hard acceleration - I thought I was just missing 3rd, and had to stab it again. Ed, your recommendation in part is to move the shifter forward to the middle position. I'm not sure I would want to do that, having to cut the trans tunnel and carpet for a new location - and I also want to keep the original looking mustang reversed stick shift. Would making the internal only upgrades help with this problem, and possibly the aforementioned problem as well?

|

This problem has several dimensions. One is the slop that the shift rod from the mid shift to the rear shift position introduces. While not attractive it is usually not the problem at the front of the parade (other than the shift lever lock up problem).

The higher order contributors to the problem, as Liberty explained it to me, were the antiquated 1960's style brass synchronizer rings Tremec uses, the timing of the interlocks machined into the shift rails to prevent engaging two gears simultaneously, and the poorly prepared sliding surfaces for the hubs and sliders. The OEM steel shift forks don't move as smoothly in the synchro sliders as they do when you add the bronze shift fork pads to them, which I would think Tremec would just do for the as delivered transmission, but they don't.

The biggest deals are the synchros and the interlocks. the carbon fiber lined synchros give a lot of new life to the old design but are not as good as the double and triple cone designs used in the T-56 Magnum. None the less they are a big improvement over the OEM brass rings.

When the first carbon fiber lined synchro rings came out, almost 10 years ago now, the manufacturers did not always have the carbon fiber correctly positioned on every synchro and created a new set of shifting problems. I have not heard of that in recent years.

The new and improved interlock timing on Liberty's replacement shift rails is the second last part of the 2 - 3 shift quality problem. The last piece is a slightly modified shift lug, which you can see in the Forte mid shift pics. I'll get as big a pic of this item as I can and post it up in a day or so. The mod made to the lug is small but Forte includes it in his shifter kit and maintains it is important to a happy ending.

In the FWIW bucket, while Hanlon does not show the shift lug in any of his Mid Shift Kit pics that does not mean he does not offer it. I discovered Hanlon after I bought the Forte kit and never called them to ask about the lug. It is entirely possible they also provide / offer it.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 10-01-2020 at 09:15 PM..

Reason: Spelling & Grammar

|

09-25-2020, 03:15 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

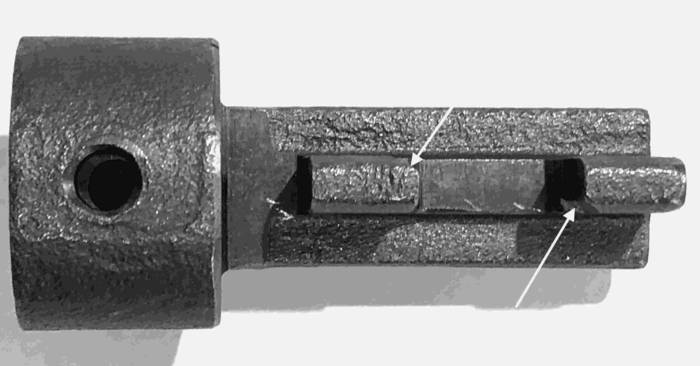

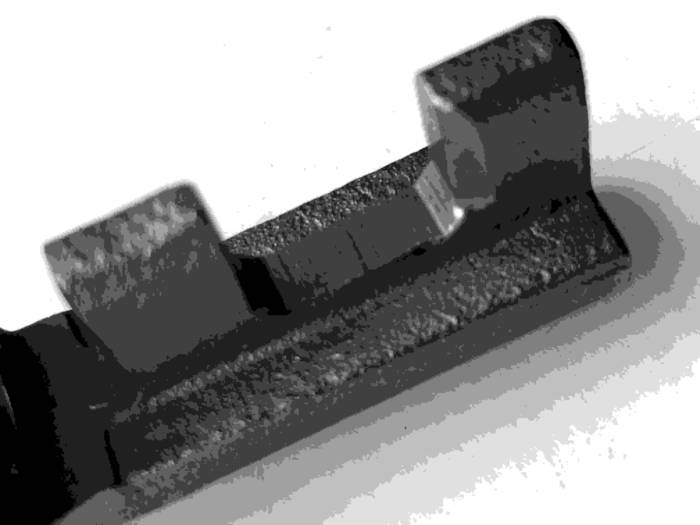

Here are some pics of the Tremec modified Midshift Lug that Forte (and I suspect Hanlon also) ships. This first pic is the top view;

The white arrows point to the light bevels that Tremec puts on the shift dog to help the shift gate transition from second gear into third gear.

Here is another oblique view from the right with a little more clarity;

The bevel is more visible but no larger here.

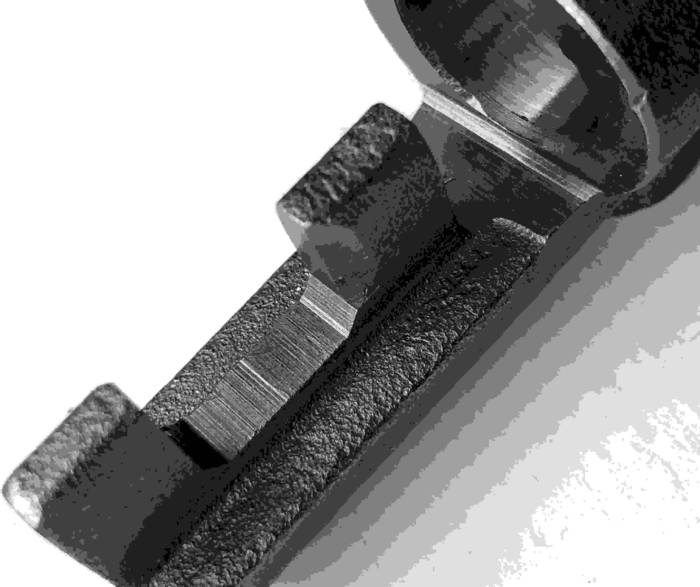

The pic below is the same shift dog with an oblique view from the left;

My TKO already had the modified shift dog, I suspect, because I originally ordered the trans with the mid shift conversion from Keisler when they were still around. If you have the standard shift location you will need the lug that Forte and I suspect Hanlon provide when you order their Midshift kit.

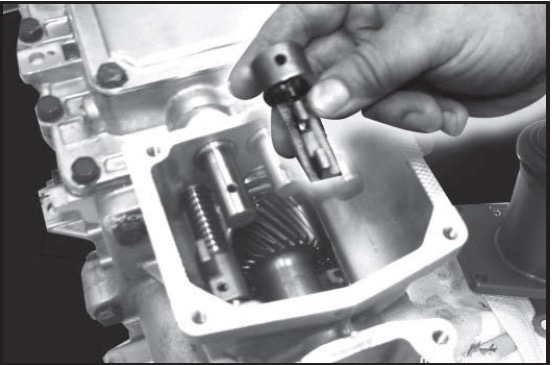

This is a pic out of the Tremec Midshift conversion instructions that shows where this lug fits in the bigger picture.

You can download the Midshift conversion instructions directly from the Tremec site.

I believe the carbon fiber faced synchros and the new shift rails with the improved interlock timing will make a huge difference even in the rear shifter position units.

And, just in case you have never seen one, this is what a carbon fiber faced synchro looks like;

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 09-25-2020 at 05:17 PM..

Reason: Added Carbon Faced Synchro Pic

|

10-01-2020, 07:34 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Midlothian,

TX

Cobra Make, Engine: Hurricane 427 Cobra #HM2008, Craft Performance 427w 600hp/600tq, TKO-600 close ratio, original Smiths gauges, lucas switches

Posts: 1,022

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bwcobra15

Very good info, Paul -- reminder: I have the Tilton hydraulic TOB, so no slave cylinder or clutch lever arm  I"ll confirm which M/C I have tomorrow night when i get back home. |

Paul, I finally got under the cobra to check the MC size. Wilwood Compact Remote Reservoir Master Cylinder .750" bore:

https://www.wilwood.com/mastercylind...temno=260-6089

The other sizes available are .700 and .625 bore. So can I go down to move more fluid to the Tilton HTOB.

I inspected the HTOB and didnt see any leakage. I does look very close to the clutch forks, although I could rotate the bearing by hand. I know the forks will move closer to the TOB as the clutch disk wears thinner, but I don't think its a problem. I certainly don't have any slippage.

This is Saturday I will get the wife to depress the clutch so I can attempt to measure the movement distance of the HTOB.

Lastly, ironically, I drove it 200 miles last weekend and didn't have any problem shifting into first. Most of it was highway driving, but still didn't have a problem when I stopped. Its very erratic, this behavior.

__________________

Bob Worley

Hurricane HM-2008 build is done!! (for now....)

Craft Perfomance 427W / 600hp / 600tq - TKO600

I love it and I need it I bleed it ~ Yeah it's a wild hurricane ~ Alright, hold tight, I'm a highway star!!

Last edited by bwcobra15; 10-01-2020 at 07:41 PM..

|

10-01-2020, 08:01 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Manchester,

MO

Cobra Make, Engine: Hurricane - FE

Posts: 627

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bwcobra15

. . . other sizes available are .700 and .625 bore. So can I go down to move more fluid to the Tilton HTOB.

|

Bobby

Going down is going the wrong direction. The smaller puck will move LESS fluid with the same amount of movement.

According to the Tilton installation page ( https://tiltonracing.com/wp-content/...ies-HRB-V2.pdf) According to their page, 3/4" would work if you get about 1.3" of cylinder movement. Which I suspect you are not, especially since you lengthened the pedal. You probably should be looking at a 13/16" cylinder and figuring out how to modify your pedal lengths and stops so you are getting 1-1/4" of cylinder puck movement.

Paul |

10-05-2020, 09:36 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Midlothian,

TX

Cobra Make, Engine: Hurricane 427 Cobra #HM2008, Craft Performance 427w 600hp/600tq, TKO-600 close ratio, original Smiths gauges, lucas switches

Posts: 1,022

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PaulProe

Bobby

Going down is going the wrong direction. The smaller puck will move LESS fluid with the same amount of movement.

According to the Tilton installation page ( https://tiltonracing.com/wp-content/...ies-HRB-V2.pdf) According to their page, 3/4" would work if you get about 1.3" of cylinder movement. Which I suspect you are not, especially since you lengthened the pedal. You probably should be looking at a 13/16" cylinder and figuring out how to modify your pedal lengths and stops so you are getting 1-1/4" of cylinder puck movement.

Paul |

Paul,

This weekend I was able to get the wife to work the pedal while I attempted to get hands, tape measure and iPhone all up in there while laying on the driveway for some rough measurements ...

at rest it shows about 1-3/4", and with the pedal fully depressed it shows 2-3/8" - for a total movement of about 5/8" (0.625").

The thing is: when I am driving from a stop, if I have the clutch FULLY pressed in, (and i'm guessing by "feel") when i slowly release, the pedal probably moves two-thirds of the full range before the clutch begins to engage and the car starts to move. So it seems to me the clutch is fully releasing.

AND - I dont think there is a larger Wilwood M/C than .750 in the style I'm using. Actually I found another model that is similar, in 13/16", but with a shorter stroke (1.25" vs. 1.40")

https://www.wilwood.com/mastercylind...emno=260-15092

Anyway, i'm leaving in 33 hours for San Marcos - 252 miles each way - with hundreds of hill country miles in between. Hope it behaves !

__________________

Bob Worley

Hurricane HM-2008 build is done!! (for now....)

Craft Perfomance 427W / 600hp / 600tq - TKO600

I love it and I need it I bleed it ~ Yeah it's a wild hurricane ~ Alright, hold tight, I'm a highway star!!

Last edited by bwcobra15; 10-06-2020 at 09:08 AM..

|

10-05-2020, 10:45 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Bob,

Looking at your pics, if the 2nd is 2-3/8, the 1st is closer to 1-7/8 at best, possibly 1-15/16, which then gives 7/16 to 1/2 inch.

Gary

__________________

Gary

Gold Certified Holden Technician

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:35 AM.

Links monetized by VigLink

|