Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

10-15-2007, 10:01 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: ****son, TN,

TN

Cobra Make, Engine: Midstates, 400M/Cleveland

Posts: 28

|

|

Not Ranked

Not Ranked

Valve clearance risk?

Valve clearance risk?

Hey, all.

I'm in the process of finishing up a a Cleveland 400M in a Midstates project that was started by a previous owner. Here's a list of the engine's innards:

- 4V closed chambered heads with stainless 2.19 int and 1.71 exh valves with 3 angle valve job and Crane double springs and retainers

- 030 over on block with Speedpro forged pistons with moly rings

- Crank.010/.010 with peened rods with ARP bolts

- Ford Motorsports cam 536 lift, 290 duration with Rhodes lifters

My question: With the specs above, how important is it to check clearance between valves and top of pistons with modeling clay?

Several engine builders have told me that with my specs I shouldn't have to t worry about crunching the valves and/or pistons from excessive valve travel. I just put the intake manifold on last weekend but I'd rather pull the whole engine apart again and check clearances if ya'll think it'd be wise.

Thanks for the help in advance.

|

10-15-2007, 11:26 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Have you seen this thread yet?

When Stroker Motors Go Bad....

Covers exactly what your talking about! Do you need to? I won't hazard a guess on that...

Now the question becomes: If you DO find theres a clearance issue, whats your plan to fix it? Checking it is one thing, fixing it is another!

Last edited by Excaliber; 10-15-2007 at 11:29 PM..

|

10-16-2007, 05:19 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

It's always wise. I wouldn't assemble an engine without doing it. If a lot of minor issues stack up against you, such as the piston deck height being out of spec, the cam not being ground the correct way (did you degree it?), using 1.7 rockers on a cam that's designed for 1.6's, etc....then that piston/valve clearance could go away in a hurry.

With your lifters, you will either need to use checking springs, or if you don't wanna take your heads apart, I'd use a solid lifter.

|

10-16-2007, 06:06 AM

|

|

Renegade Nuns on Wheels

|

|

|

Join Date: Aug 2001

Location: columbus,

Oh

Cobra Make, Engine: Unique 427 roadster with 351C-4B

Posts: 5,129

|

|

Not Ranked

Not Ranked

Don't take the motor apart to check valve clearence. The clay method ranks right up there for accuracy with plastigauge, close, but not exact. Put in a checking spring on an intake and exhaust and check clearences with a dial indicator. While you are at it, you can degree the cam. .1 for exhaust and .08 for intake in general.

|

10-16-2007, 09:08 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

Jeff: It's always safe to error on the safe side, so I recommmend that you check piston-to-valve clearances. I go over both methods--clay or dial indicator--in detail in Racing Engine Builder's Handbook. Either way, you should have 0.100-in. minimum axial clearance and 0.050-in. radial clearance when using steel rods. Install the head with an old head gasket to give the correct piston-to-head clearance.

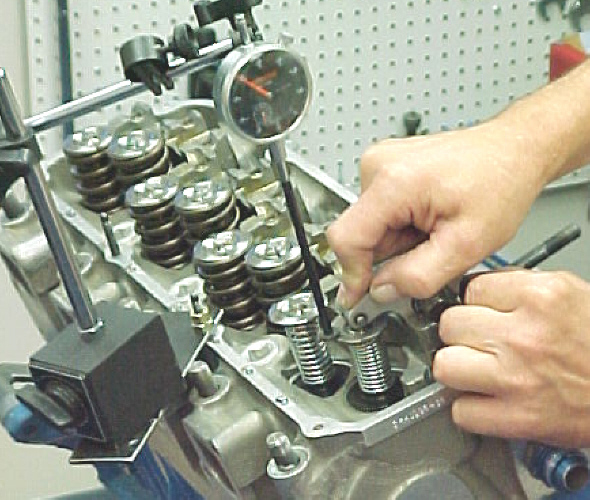

Using the age-old clay mash method works well, but I prefer using bounce springs in place of the valve springs. Set up a dial indicator square to the spring retainer to see how much clearance there actually is at different crank positions. Either way, you'll need a degree wheel at the crank. Using the indicator method, just push down on the valve end of the rocker arm to open the valve farther to check actual clearance. See photo from the book.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

|

10-16-2007, 11:08 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: ****son, TN,

TN

Cobra Make, Engine: Midstates, 400M/Cleveland

Posts: 28

|

|

Not Ranked

Not Ranked

more on clearance (moron?)

more on clearance (moron?)

To Excaliber: Thanks for the info. Yup, I noticed the "Stroker motor" horror story post. It got me thinking about double-checking things.

To Speed220mph or anyone else: Since the intake is in place (pain in the butt on this engine) how does one pull the valve springs off of an engine that has it's heads in place? Plus, I've got hydraulic lifters. If I pump up the lifters with a drill on the oil pump shaft will I get an accurate reading with a dial indicator before the lifter settles a bit? |

10-16-2007, 11:17 AM

|

|

Renegade Nuns on Wheels

|

|

|

Join Date: Aug 2001

Location: columbus,

Oh

Cobra Make, Engine: Unique 427 roadster with 351C-4B

Posts: 5,129

|

|

Not Ranked

Not Ranked

Compressed air and a valve spring compressor. Old trick was to feed rope in the spark plug hole as it is coming up on compression and then by HAND turn it until it stopped.

|

10-16-2007, 11:24 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

Jeff: The procedure to remove the valve springs on an assembled engine is to bring the piston up to TDC, then pressurize the cylinder. You'll need compressed air and an adapter for the sparkplug holes. This will hold the valves closed while you compress the spring and remove the retainers and springs. Install the bounce springs and retainers, then release the pressure.

About the lifters, you know there's a gross valve lift on the cam card. So don't worry about bleed-down. Instead, measure head-to-retainer distance with the valve closed, then turn the crank and check piston-to-valve clearance. Using the degree wheel and knowing where max valve lift occurs, measure head-to-retainer distance and check it against what you measured when the valve was closed. If it's less than the published maximum valve opening, that's the result of bleed down. Factor it in when checking piston-to-valve clearance. Nothing to it.

Reverse the procedure to install the springs, assuming you don't have to pull the heads and pistons to have the valve reliefs cut. Sure beats assembling your engine just to find out the valves and pistons colide.

Good luck.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

Last edited by speed220mph; 10-16-2007 at 11:28 AM..

|

10-18-2007, 02:23 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: ****son, TN,

TN

Cobra Make, Engine: Midstates, 400M/Cleveland

Posts: 28

|

|

Not Ranked

Not Ranked

more on clearance

more on clearance

Thanks guys. I'll be checking clearance this weekend with my trusty new micromete. For those interested, I'll let you know what I find.

|

10-18-2007, 02:47 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I used compressed air and a ball joint breaker tool on mine.

|

10-27-2007, 11:06 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: ****son, TN,

TN

Cobra Make, Engine: Midstates, 400M/Cleveland

Posts: 28

|

|

Not Ranked

Not Ranked

valve clearance okay

valve clearance okay

Thanks for the input. Instead of pulling off the springs, I made a tool out of oak and copper to arc the rocker and compress the spring at TDC. Found I have more than enough clearance. The previous owner who mocked up the engine told me that the Speedpro pistons had been cut out for valve clearance and he was right. Resting easier now. The engine is going back into the car this weekend!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:27 AM.

Links monetized by VigLink

|