Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

04-09-2008, 10:57 PM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

TIG welding is fun!

TIG welding is fun!

I have had a MIG welder for 4-5 years and have it down ok, though it's like starting over each time I do it because it's been far and few times between that I use it.

I have always wanted to TIG so that I could do aluminum, as I get a kick out of toying with the material. On my new project: http://http://www.clubcobra.com/foru...ad.php?t=85745 I have a lot of aluminum welding projects planned, such as an original style expansion tank, original style oil tank (won't be functional, as it will just be in the proper place and covering the battery), turkey pan (a bit different than the cobra ones), oil coler mounts, and plenty of odds and ends.

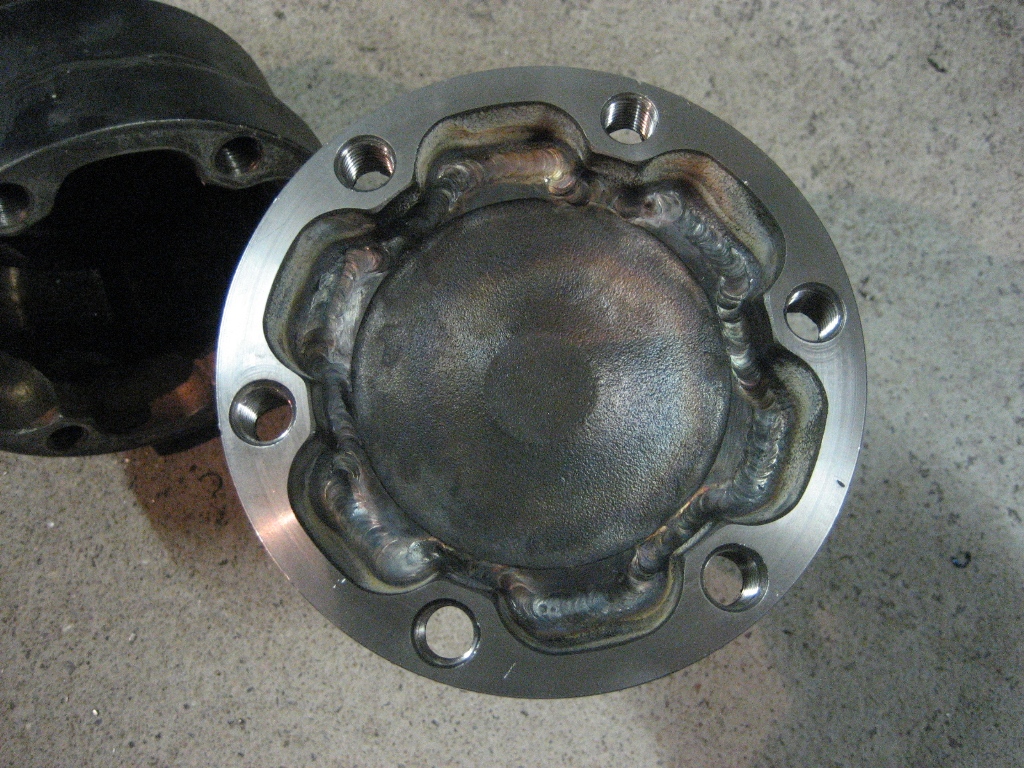

Well, I didn't want to spend a bazillion dollars on a top quality Miller/Hobart/etc, so I did a lot of research and decided to buy one off of Ebay...Don't kill me...it's Chinese. I'm not a big fan of that stuff typically, but the reviews from folks were quite good and the price was really really right. So far, I'm super happy with it. It's a 200amp unit with foot pedal, with most of the control features that the big boys have. I have tinkered for the last couple nights after work, and I'm actually getting the hang of it even on really thin sheet. Below are some pictures of a couple pieces I just welded together...Not perfect, and once hit the tungsten on the filler and all hell broke loose (it's obvious where that happened).  I guess the point is that I feel like with more practice, I should be able to do everything I need to do. It is interesting getting used to being steady with one hand, dipping the filler with the other, and working the foot pedal simultaneously, but it is quite fun!

Ok, pros, I'll take tips, but don't rag on me too much for the below pics...it is thin sheet aluminum and only about 2hrs practice.

|

04-09-2008, 11:26 PM

|

|

CC Member

|

|

|

Join Date: Jan 2005

Location: Auburn,

ca

Cobra Make, Engine: Unique 289 FIA HiPo 289 with Shelby dual quad intake

Posts: 187

|

|

Not Ranked

Not Ranked

Brent, Looks like the good, the bad, and the ugly.

I would like to have a TIG setup myself, but the price has been my excuse so far. I actually have gotten fair results, somewhat often with my MIG welder on aluminum. A little more practice and you will be all set. |

04-09-2008, 11:41 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I love my TIG.

I've had a good MIG machine for 16 years or so and I'm pretty handy with it. I bought a DC TIG about 10 years back and got a lot of use out of it but it was only suitable for steel and stainless.

Last year I bought a 200Amp AC/DC TIG and I've been having a great time with it. There have been lots of aluminium welding projects I've been wanting to do but couldn't. The new machine has a HF start and up slope and down slope adjustments which make for a much better quality weld. It also makes it so much more satisfying to use.

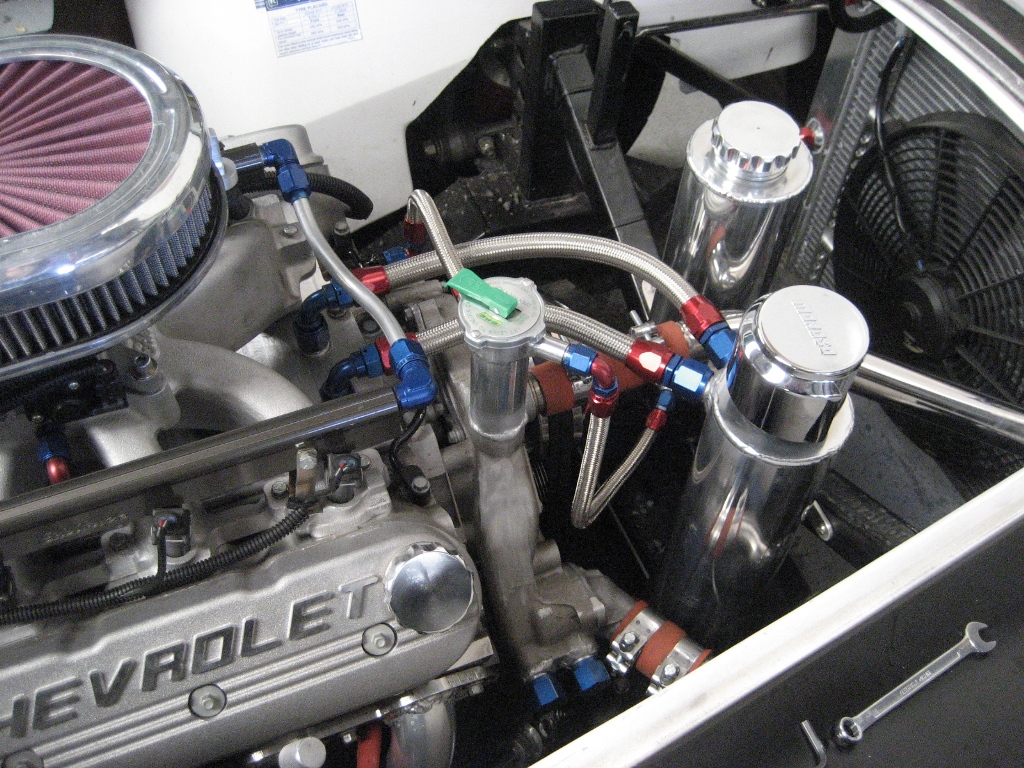

I've built all me chrome molly rear suspension arms with the TIG and fabricated catch cans and other goodies. An AC/DC TIG opens up a hole buch of oportunities for workshop fun.

In this pic I've fabricated both catch cans, welded the pressure cap fitting to the water pump, welded AN#10 barbs into the the valley plate, welded the stainles radiator pipes together and welded the filler cap into the rocker cover. You'll find a heap of jobs for your TIG.

If you need any pointers just ask. There are a few welders on here. I'm an amature, pretty much self taught and still learning but there are a few real pros on here.

Have fun.

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 04-09-2008 at 11:45 PM..

|

04-09-2008, 11:51 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I should add that my TIG is a Chinese unit bought off ebay. My previous machine I bought when I was working in China and brought back in my luggage. I also brought back a 40 Amp plasma. They've all performed great. You may need something better as a professional welding all day every day but for a home fabricator they are brilliant.

This is what mine looks like

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-09-2008, 11:59 PM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Mike, that is essentially the unit I purchased as well...Riland brand, but same unit (as I understand it, the Jasic and Riland are built by same factory).

I have a lot more practice to get to your level, but on the thicker metal, I have been able to run really good beads...I goof up every once in a while of course, but when I get in a rythm, it turns out nice. The thin metal in my shots was a challenge, as it's really easy to burn through.

|

04-10-2008, 12:16 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Mine is a Mitec brand but most of them seem to come out of the same factory and they paint them up for different suppliers. My old one was a WSE or something like that and the plasma is a Riland.

Welding thin materials is always a challenge. Stainless and Steel is not to hard. I use thiorated (sp?) electrodes on steel these have a red painted end. Grind them to a tapered sharp point and have the wheel running in the same direction at the electrode i.e don't grind across it seems to stuff up the shape of the arc. You should also wear a dust mask when grinding them as they are mildly radioactive.

For aluminium use just straight tungsten (white painted end). Don't grind them, just run them straight out of the packet. They will round the end over nicely as you use them.

A few factors that improved the quality of my welds:

Get a good quality automatic welding helmet that lets you adjust the shade as well as the delay switch off delay and sensitivity. When you are tig welding you are generally not making such a bright arc as with mig so the cheap helmets can flicker on and off. adjusting to the lightest comfortable shade will let you better see and control the weld pool. Mine cost about $300 but it was well worth it.

Pick up a gas lense for your torch. They aren't that expensive. I found it gave much better results as the argon was shielding weld better.

TIG Torch Article

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 04-10-2008 at 12:40 AM..

Reason: spelling

|

04-10-2008, 04:01 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

Mike, thanks for that info, I have been dithering about buying a -modern- replacement for my old tig, there is so much '' barstool expert'' advice out there about some of these machines that its great to get an opinion & with photos to back it up.

cheers

Jac Mac

|

04-10-2008, 04:46 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

Hey Brent, looks good. You already know the answer, practice. Ally is kind of a head trip to weld as the magnesium is catching fire and the weld is frying away. The best tip I can give (apart from practice) is to commit to just get in there and get it melting first then get a good rythm going on your feed. Get set up comfortably and use an Amp per thou of thickness. There's more info than you can shake a stick at here http://www.millerwelds.com/education...les_search.php

Good stuff keep it up. |

04-10-2008, 05:11 AM

|

|

CC Member

|

|

|

Join Date: Jul 2001

Location: Senoia,

Ga.

Cobra Make, Engine: 427SO with big twin autolite inlines on custom intake, jag rear, top loader, wembeldon white, guardsmen blue stripes

Posts: 3,155

|

|

Not Ranked

Not Ranked

Looks like you already know the first rule when welding aluminum, clean...clean...and then, clean again. My expansion tank and filler neck were fabricated from aluminum, I wanted something a little more compact.

__________________

Perry

Remember!, there's a huge difference between a 'parts' changer, and a mechanic.

|

04-10-2008, 06:01 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I would love to have a $5000 TIG welder sitting in the shed but I could only justify $1300. Realistically I don't think with my back yard skill level I could tell the difference using the pro machine.

Buy yourself a couple of stainless steel wire brushes and write aluminium only in big letters on them with a permanent marker. Also build yourself a welding trolley that you can wheel to the job, has holders for filler rods, some hooks to hang your lines up on and a secure mounting for your bottle. I find I use the TIG much more now I'm not having to pull ot off the shelf and set it up.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-10-2008, 06:37 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: atlantic beach,

ny

Cobra Make, Engine: hurricane 1075

Posts: 148

|

|

Not Ranked

Not Ranked

what is the brand plasma you are speaking of?

I'm a wood worker by trade but have found new respect for high quality tig welds I bought a machine and have been practicing

Bobby

|

04-10-2008, 10:54 AM

|

|

CC Member

|

|

|

Join Date: Apr 2000

Location: Austin,

TX

Cobra Make, Engine: ERA 427 SC - #463 - 427 SOHC

Posts: 269

|

|

Not Ranked

Not Ranked

Email issue????

Email issue????

Brent,

I have been trying to get an email to you with the address you have listed in Club Cobra.............it keeps coming back undeliverable.

Can you send an email to Cammer on the Texas Cobra Club forum with your correct address.................I need to discuss something with you????

Dee Walters/Cammer

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:28 PM.

Links monetized by VigLink

|