Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

01-09-2009, 09:12 PM

|

|

CC Member

|

|

|

Join Date: Dec 2002

Location: Apopka,

FL

Cobra Make, Engine: Building 289 Lemans / FFR mkIV chassis w/ Bruce Chervenak

Posts: 700

|

|

Not Ranked

Not Ranked

Unbelievable. David, it's a credit to you that you're taking on this project to try and help these guys. Nice going.

|

01-09-2009, 11:03 PM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: Cape Town, South Africa/Mainz, Germany,

Posts: 1,601

|

|

Not Ranked

Not Ranked

concentric?

concentric?

Nice going! :-)

Please can someone fit the pins on a stud or bolt and turn them in a lathe or drill press.

I would like to know if they are concentric. Or how much they "run out".

You could also fit them (2) on a hub. Measure the gap with a vernier caliper between the two. Then turn them half a turn and measure again. Do that until you get the biggest difference.

Dom

__________________

If I don't respond anymore, that's because I can't log in

|

01-09-2009, 11:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Dom,

No, they are not concentric. You can tell just by screwing them on. I will post TIR tomorrow. I was too busy to measure accurately, but when I saw them wobbling, I gave up and moved on to other things.

I will post some very, very interesting photos tomorrow.

David

|

01-10-2009, 09:13 AM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,037

|

|

Not Ranked

Not Ranked

Now that David mentions it, I took a look at the hub and pins on my Compomotive set and I see the same thing. I don't have an angle measureometer, but it's clear the pin has a smaller angle than the hub. I'll take some pictures and you will see the engagement of the pin is only partial, near the hole of the hub.

|

01-10-2009, 09:27 AM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: monroe,nc,us,

nc

Cobra Make, Engine: A&C 408 stroker

Posts: 33

|

|

Not Ranked

Not Ranked

I don't know which adapters you are talking about but three weeks ago I recieved a new set of Vintage wheels and adapters from Bob at Vintage everything bolted up perfectly although some pins with external hex heads would be nice, after reading about the problems about concentricity and taper I looked at mine, first I checked the taper, I put machinest blue dye on the pins and tightned them down,I had full contact (the taper appeared to be the same pin and hole) then I set up a dial indicator on a machined surface of the hub the most out of concentricity i could find is appx. .004-.006 all said I don't know about other wheel manufactures but the Vintage wheels were spot on, however the pins could be improved. When it is all worked out I will be in line for improved pins.

|

01-10-2009, 09:55 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by butz999

I don't know which adapters you are talking about but three weeks ago I recieved a new set of Vintage wheels and adapters from Bob at Vintage everything bolted up perfectly although some pins with external hex heads would be nice, after reading about the problems about concentricity and taper I looked at mine, first I checked the taper, I put machinest blue dye on the pins and tightned them down,I had full contact (the taper appeared to be the same pin and hole) then I set up a dial indicator on a machined surface of the hub the most out of concentricity i could find is appx. .004-.006 all said I don't know about other wheel manufactures but the Vintage wheels were spot on, however the pins could be improved. When it is all worked out I will be in line for improved pins.

|

I would not call 0.004-0.006 of an inch "spot on." Especially if we are talking about a hub. We hold our hub concentricity to under 0.001 inches. Modern automotive manufacturers hold concentricity in the microns on hubs.

Additionally, it is critical WHERE you take the measurement. If you took the measurement out at the OUTBOARD end of the hub (out at then end of the threads), it will not be the same next to the inboard side of the hub. Remember, a wobble of 0.006" at the inboard side of the hub could translate to substantially more out at the end of the hub--which may translate to who-knows-what out at the WHEEL. (Think of the distances involved.) Now think of the run-out of the rim and the run-out of the tire and add the whole mess together and your heart starts to pulse unevenly...not to mention the brakes too.

David

|

01-10-2009, 10:08 AM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: monroe,nc,us,

nc

Cobra Make, Engine: A&C 408 stroker

Posts: 33

|

|

Not Ranked

Not Ranked

What I am saying is the runout of the adapter matched the runout of the hubs, you are working with new piece by piece manufactured parts we are working with 30 year old stuf. My car is smooth as silk at any speeds I had it to. The vintage hubs were truely machined concentically.

|

01-10-2009, 10:24 AM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,037

|

|

Not Ranked

Not Ranked

Pictures of Compomotive Hub and Pin Drive

Pictures of Compomotive Hub and Pin Drive

Here are some pictures of the Compomotive hub and pin. I suspect Trigo uses the same pin, manufactured by someone else. David, let us know if they look like the same piece.

From the pictures, it's clear there are two different angles. The 76 degrees that David measured on the pin and then perhaps 90 degrees on the hub.

Here is the hub, pin drive and hex wrench

Here is the pin showing the contact area with the hub. Notice its only contacting on the inner edge.

Here is the hub showing the same contact on the inner edge.

Clearly two different angles. |

01-10-2009, 10:26 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Unless you start measuring for runout @ the flange you are bolting the adapter to it's not possible to know whether the runout is the fault of the hub or other factors.

Craig

|

01-10-2009, 10:37 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Paul F

Great photos, very helpfull.

Must have a fantastic camera to take clear closeups like those.

It is interesting that we are all just getting into this after all the years of using adaptors.

Excellent thread.

Thanks Craig

|

01-10-2009, 12:04 PM

|

|

Senior ClubCobra Member

|

|

|

Join Date: Feb 2006

Location: Northern,

Ca

Cobra Make, Engine: LA Exotics

Posts: 1,037

|

|

Not Ranked

Not Ranked

Thanks Craig. It is a Nikon Coolpix S550 that has a macro mode that let's me get in very close. With 10Mpixels, I was able to blow it up further on a photo editor without it pixelating (is that a word?). I'm quite surprised and pleased with the results. First time I used the macro.

I agree about the pin drive discussion. When we settle down on this, I want to bring up a similar discussion about the spinners.

|

01-10-2009, 12:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Gents:

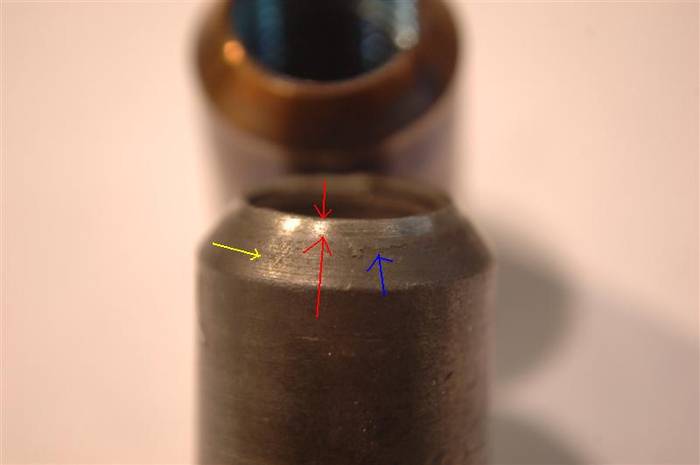

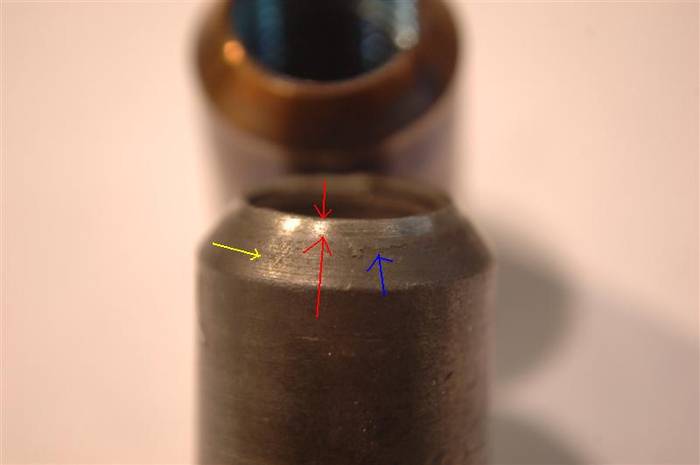

Paul F. kindly sent me this pin. This, I think, is what started the whole discussion. Notice the cracks...this death deserves an autopsy. You never know what you'll find.

For clarity, this is Compomotive part. I am beginning to think Compomotive and Trigo got these nuts from the same place because the measure out the same and look the same.

David

Last edited by David Kirkham; 01-10-2009 at 12:16 PM..

|

01-10-2009, 12:15 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is the other side of the pin. Notice the fine tapered edge is quite ragged. Between the arrows, there is a part of the taper that is actually missing.

Last edited by David Kirkham; 01-10-2009 at 12:20 PM..

|

01-10-2009, 12:27 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now, things get interesting.

Between the red arrows, you can see a bright, shiny ring that goes all the way around the very end of the pin. That ring is where the black oxide coating has been scraped off the pin as it was tightened into the hub adapter.

That ring is the ONLY contact point where the male taper of the pin contacts the female taper of the hub adapter. Notice it does NOT make full contact.

|

01-10-2009, 12:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

The yellow arrow shows the machining marks from the lathe that was used to make the taper.

|

01-10-2009, 12:32 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

The blue arrow points to junk from the black oxide process.

|

01-10-2009, 12:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

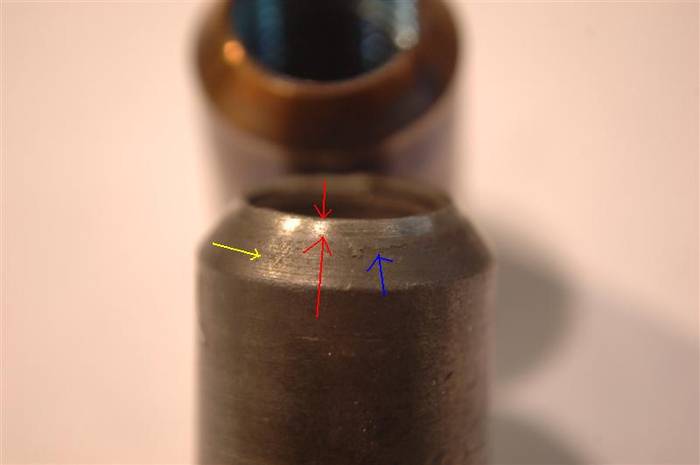

Now, this is a pin from CNGreen. It is most interesting. I doubt he even saw this.

This is a Trigo pin. The taper has actually started to crack. Again, notice the thin, shiny ring where the contact angle of the pin did not line up to the countersink on the hub adapter. Thankfully, he sent me his hub adapter as well.

This should put to rest the nonsense of outside corners not being stress raisers--this picture states other wise. ANY sharp edge is a potential to cause you grief.

The tape around the pin marks it as coming from CNGreen. (Had to keep all this stuff straight).

The plot thickens...

Last edited by David Kirkham; 01-10-2009 at 12:44 PM..

|

01-10-2009, 12:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

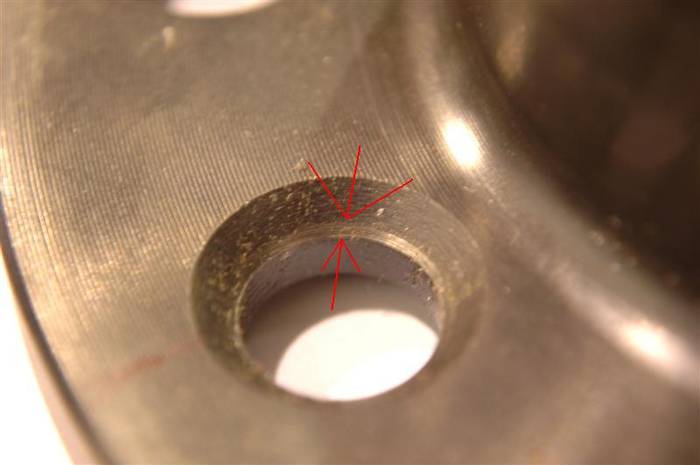

Here is the hub from CNGreen. This is a Trigo hub adapter.

Again, notice the shiny ring where the pin contacted the hub adapter. Notice it is extremely small. This is not a good situation.

|

01-10-2009, 01:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is an exaggerated view of what is going on.

This picture is of a Trigo pin. The pin is lathed to a 76 degree taper and the hub adapter is represented by the red lines.

|

01-10-2009, 01:01 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Cobra Make, Engine: SPF#0760

Posts: 3,405

|

|

Not Ranked

Not Ranked

Interesting, but I wonder how this fit-up differs from the hundreds of millions of regular passenger cars on the road today with regular lugs nut holding their wheels on? Still, it doesn't reflect well on the quality control practices in place of these preminm wheel manufacturers does it.

__________________

Wiring Diagrams: SPF MKII, MKIII, GT40, CSX7000, CSX8000, Corvette Grand Sport, and Shelby Sebring, Bondurant & Cinema Tribute Cars.

Owner’s Manuals: SPF MKII, CSX7000, CSX8000, Sebring, Bondurant, Cinema Tribute Cars $ GT40’s..

Large, easy to read and trace schematics with part numbers, wire colors, wire gauge, fuses, and electrical upgrade information. Trouble-shooting and replacement part numbers for those roadside repair adventures.

SPFWiringDiagrams@Comcast.net

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:18 PM.

Links monetized by VigLink

|