Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

11Likes 11Likes

08-28-2023, 03:52 PM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Neutral

Neutral

Drive train - angle of the dangle

Drive train - angle of the dangle

I am building a '67 427 replica (Antique & Collectibles ) and have run into an issue.

- I'm running a '69 429 (Stroked to 460)

- T10 BW 4 speed (Long tail shaft)

- 9" ford rear

- 11" drive shaft (Custom build)

I installed the engine mounts per directions (about 10 years ago), added T-10 and had 9"ford rearend.

Issue is that the T-10 has a long tail shaft and ends up below the CL of the rear end. This throws off the drive line. Engine -2.55* ; drive shaft + 4.7* and rear about 3* up(pointing up towards motor).

So my drive train goes down; up; then down. I believe this is bad.....

My initial thought is

- to remount engine/tranny about 2" higher? (Not sure if I'll have hood clearance)

- or find a shorter tail shaft so it ends above the CL of rear end..

Suggestions????

Also - does anyone else know what is the correct motor mounts should be?

Thanks all!

PJ

|

08-28-2023, 04:24 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

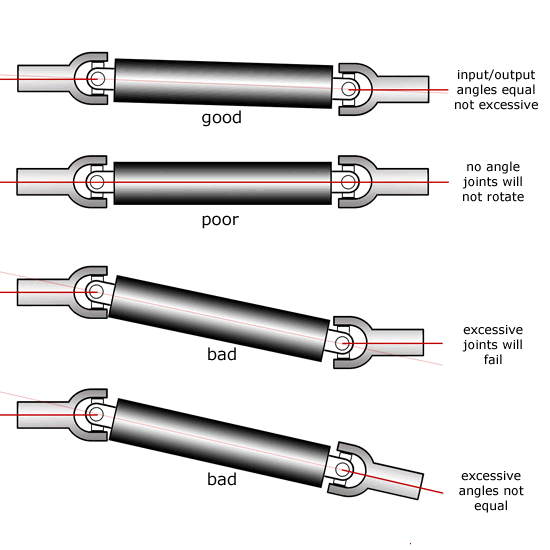

If your tail shaft ends up below the centerline of your pinion, you have some fairly significant problems! Here is a graphic of the correct alignment (top pic) and various versions of bad alignment;

You want the top solution. The happy angle threshold is somewhere between 4 and 7 degrees. Bigger and smaller angles will work, but they will bring varying levels of vibrational unhappiness. Really big angles will rock you and eventually result in parts breakage. A zero or near zero angle will use up u-joints. Unequal angles are just stupid bad.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 08-28-2023 at 04:28 PM..

Reason: fixed broken pic links

|

08-28-2023, 11:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

I would shim the pinion down 1 degree. Depending how your rear is mounted under load it should become equal and parallel with your trans angle. Your pinion being higher than your trans output is common on a lot of cars that sit low with tall tires. Yes a shorter tail housing would help with the u joint working angles if they are too sever.

|

08-29-2023, 08:02 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by MAStuart

I would shim the pinion down 1 degree. Depending how your rear is mounted under load it should become equal and parallel with your trans angle. Your pinion being higher than your trans output is common on a lot of cars that sit low with tall tires. Yes a shorter tail housing would help with the u joint working angles if they are too sever.

|

Using a non-IRS rear suspension on a drag car this approach will provide a better mechanical operation and vehicle performance under launch and hard acceleration. On a daily driver, it will insure your alignment is continuously off by whatever amount you have shimmed the pinion down.

On an IRS, the center section is bolted to the chassis and is, for all intents, unmoveable. The pinion-down shimming model will not produce the desired results; in fact, just the contrary. It would be better to set the driveline up as in the top pic in post #2.

In the end, it is the OP's call, and by definition, whatever he decides will be right, at least for him. The equal angles install model will provide smooth operation and the longest driveline life.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

08-29-2023, 08:26 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

In most cases the rear is not ridge. There is some deflection even with hiem joints. With rubber or urethane in the system even more deflect. So in his case under load its going to be pretty parallel. In his case the pinion is going to try to climb the ring gear. Its going to end up at maybe 4 plus up. Dont know what type setup he has on his solid rear axle. might be a 4 bar or leaf who knows. If a leaf he might be able to find a 1/2, 3/4-degree shim. Just fixed a 64 Falcon just last week that other shops were stumped on and could not fix. Same drive line problem as above.

|

08-31-2023, 05:44 PM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Thanks for the input; My kit is a 67 427 replica Antique & Collectibles and it has a triangulated 4 link suspension (w/coil overs). I've included a picture from the passenger side that shows the issue. I can move my rear shocks brackets to increase the height in the rear but I'm not sure how much it will move. I am recovering from a hip replacement so it'll be a few weeks before I can check it out. Also, I think I only have about 4 inches of ground clearance between bellhousing and ground. So, raising the engine/tranny may be the best bet.

http://www.clubcobra.com/forums/memb...side-view.html

Last edited by Speedwaypj; 08-31-2023 at 05:48 PM..

Reason: pic

|

08-31-2023, 07:55 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

You change the pinion angle on four-link suspension by lengthening and shortening the upper and lower links. The shock mount will only allow you more or less suspension travel. The pinion angle is determined by the four-link linkage.

Search four-link suspension set up on YouTube. There are a number of very good videos on four-link design and setup from very reputable shops, including several with software to use on your computer to help you.

Attempting to eyeball the solution is not a good idea, nor is it likely to produce the outcome you want. Take the time to do the job right. You will be glad you did.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-03-2023, 10:22 AM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Thanks Ed, Yes I'm aware of how to set pinion angle with a 4 link. My problem is that with the current set-up the tranny output shaft is too low, it is below the CL of the pinion. This makes the driveshaft angle point up.

I will need to check the clearance with the hood and AC to see how high I can move the engine/tranny up. Not too sure what else would correct it.

I checked with A&C and I am using the suggest motor mounts but will probably need to make spacers to go between the engine and top mount to raise the engine.

Has anyone else have this problem with the driveshaft going up?

Thanks,

PJ

|

09-03-2023, 12:54 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

BorgWarner does have short tail shafts for T-10s, but when you start down that path, purely from a cost perspective, it might be better to look at an alternative transmission with a better fit lengthwise. If you go aftermarket, you can get much better strength and an OD that will make highway cruises much more enjoyable.

Using a 9" center will require you to set your engine relatively lower in the chassis because of the lower pinion placement the 9" R&P has. If you level the engine and transmission and drop it lower the chassis, you might be able to make your existing tailshaft work. That said, you will likely need a custom oil pan for ground clearance and oil volume. A lower in the chassis engine placement will be at odds with your already too-low tail shaft problem. To the extent you can level the engine in the car, you can mitigate at least some of the too-low tailshaft problem, possibly a lot!

An alternative to the lowering and leveling of the power train would be to maintain the current positioning, buy the shorter tailshaft assembly, and rotate the pinion upward to get it parallel to the crankshaft if it is not already. When you use a non-IRS rear suspension, you will want to consider placing both upper and lower suspension travel limits on the rear end so you don't pull the drive shaft out of the transmission or jamb it into it.

There are any number of 429/460 cars here that have had to confront some variation of this problem. Perhaps a few of them could chime in with how they pieced everything together.

I know a transmission change is an unattractive alternative, but something to consider: the 429/460 engine family are torque monsters. That T-10 was never envisioned as living behind one of those engines. Purely from a longevity and reduced transmission service and replacement perspective, you might want to consider exploring a stronger alternative.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-03-2023, 01:47 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Location: Spokane,

WA

Cobra Make, Engine: Shell Valley, 351W

Posts: 183

|

|

Not Ranked

Not Ranked

Hi PJ,

If your picture above is current, Just some food for thought, I think you might be early in the game in trying to set the angles. I have a Shell Valley that has a similar frame set up to the A&Cs. At the advise of this forum nearly 20 years ago, I didn't mess with the pinion angle until the car was complete and ready for paint. With the car on a lift, ride height set, concrete sacks in the seat and trunk, I adjusted the pinion to make both u joint angles the same without worrying about the driveshaft direction. When I was done, the pinion was pointed down a few degrees like the tail shaft, and the driveshaft ended up being level.

Sydney

|

09-04-2023, 11:03 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

I was looking at your picture again, PJ. It appears as if just raising the front of the engine could possibly correct the alignment problem. It is hard to say with certainty from just looking at the photo, but it is a possibility.

You want your crankshaft centerline to be parallel with the pinion centerline. That will involve moving the front of the engine upwards. You can use one of those Harbor Freight angle finders to set both angles the same.

When the two centerlines have a slight offset from being perfectly aligned, it will produce the smoothest operation and best u-joint life — essentially the "Good" image in my post#2.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-04-2023, 11:15 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

You are making a bigger deal out of it than it is. If you have room shim your trans up if you can 1/2 to 3/4 inch. Then adjust your pinion yoke down with your 4 bar. Make your pinion and engine trans centerlines parallel. Does not matter if your trans output is lower what your pinion input. There are a lot of cars that are setup like yours. If the working angle of the U joint is too severe you may need a shorter trans so your drive shaft can be longer. Look up what the working angle of a U joint is so you don't confuse it with your drive shaft angle or drive line angle.

|

09-04-2023, 01:33 PM

|

|

CC Member

|

|

|

Join Date: Feb 2018

Location: Lodi,

CA

Cobra Make, Engine: 427 manowar forged crank roller rockers . BIG CAM.

Posts: 785

|

|

Not Ranked

Not Ranked

I have a tom woods driveline in my jeep look on his website lots of great info for setting correct drivline angles

|

09-06-2023, 03:34 PM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by MAStuart

You are making a bigger deal out of it than it is. If you have room shim your trans up if you can 1/2 to 3/4 inch. Then adjust your pinion yoke down with your 4 bar. Make your pinion and engine trans centerlines parallel. Does not matter if your trans output is lower what your pinion input. There are a lot of cars that are setup like yours. If the working angle of the U joint is too severe you may need a shorter trans so your drive shaft can be longer. Look up what the working angle of a U joint is so you don't confuse it with your drive shaft angle or drive line angle.

|

So you are saying it’s ok for the driveshaft to point “uphill” as long as I follow the rules for parallel (tranny and rear) angles (around 3*) from everything I read and to ensure the working angles are within the recommendations? I have read....

- (tranny and rear end) operating angles must be less than 1° difference.

- Tranny and rear end should be parallel and no more than 3°

- U join angle should be less than three degrees to tranny and/or rear end

- Drive shaft should have at least 1/2° difference between tranny and rear end to allow the U joints to work properly.

Please correct me if I have it wrong.

Thank you,

PJ

|

09-06-2023, 03:43 PM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by eschaider

I was looking at your picture again, PJ. It appears as if just raising the front of the engine could possibly correct the alignment problem. It is hard to say with certainty from just looking at the photo, but it is a possibility.

You want your crankshaft centerline to be parallel with the pinion centerline. That will involve moving the front of the engine upwards. You can use one of those Harbor Freight angle finders to set both angles the same.

When the two centerlines have a slight offset from being perfectly aligned, it will produce the smoothest operation and best u-joint life — essentially the "Good" image in my post#2.

|

Ed,

So, can the drive shaft point upward if the drive train adheres to all the angle rules? Or will it create an undesirable torque in the wrong direction?

BTW I bought the 429 in 1971 and had the T-10 in my ‘55 Ford in ‘69. Nostalgic :-) (they did run the T-10’s behind the 406)

Thx

PJ |

09-06-2023, 04:53 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

Pointing upwards can miscommunicate the positioning. The simple answer is yes; however, you want the front of the drive shaft to be higher than the rear of the drive shaft and both to be above and parallel with the pinion centerline. It is easier to think of it in terms of parallelism.

You want the crankshaft centerline to be parallel with the centerline of the pinion. They don't need to be in line, but they do need to be parallel, hence the angle finder commentary in my post #11. The vertical offset or displacement from perfect alignment will determine vibration and U-joint life.

A 10˚angle or offset will work quite nicely, providing a smooth application of power to the rear end. As you increase this number, the car will experience increased vibration. If you could get to a zero misalignment (perfectly aligned), it would not vibrate. However, it would prematurely wear out the U-joints. As they wore, they would then begin to vibrate prior to failure.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-07-2023, 02:31 PM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Here is a right side up pic of drive train. I just Noticed that the lower link isn’t it parallel with the frame. Does that matter?

http://www.clubcobra.com/forums/memb...driveline.jpeg |

09-07-2023, 05:08 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

PJ, the simple answer is yes.

More complex answer;

There is an excellent series on 4-link set up on the web and also an excellent software tool sold by Jerry Bickel Race Cars for noodling out these sorts of things. Here is a link to one of the 4-Link vids by Kevin Wilson, click here => 4-Link Bar Angles. Kevin has a business that does this for racers. If I could not do it myself, there are only two shops I would take my car to; one is Kevin's, and the other is Jerry Bickel. Kevin is that good, and he is an excellent communicator and teacher.

If you want the s/w that does all the heavy lifting, it is available from Jerry Bickel race cars, click here => 4-Link Wizard.

The video will take about 30 minutes, and I believe it will be well worth your time.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-09-2023, 07:21 AM

|

|

CC Member

|

|

|

Join Date: Sep 2007

Location: Sanford,

FL

Cobra Make, Engine: A&C (near future)-460

Posts: 99

|

|

Not Ranked

Not Ranked

Ed,

Thanks for the link! Kevin has a lot of information there. This should be challenging.

PJ

|

09-09-2023, 10:56 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,735

|

|

Not Ranked

Not Ranked

Glad you found it helpful PJ.

When you are all done, you will be glad that you spent the time ...

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:04 PM.

Links monetized by VigLink

|