Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

04-11-2011, 11:09 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Fuel tank fabrication project

Fuel tank fabrication project

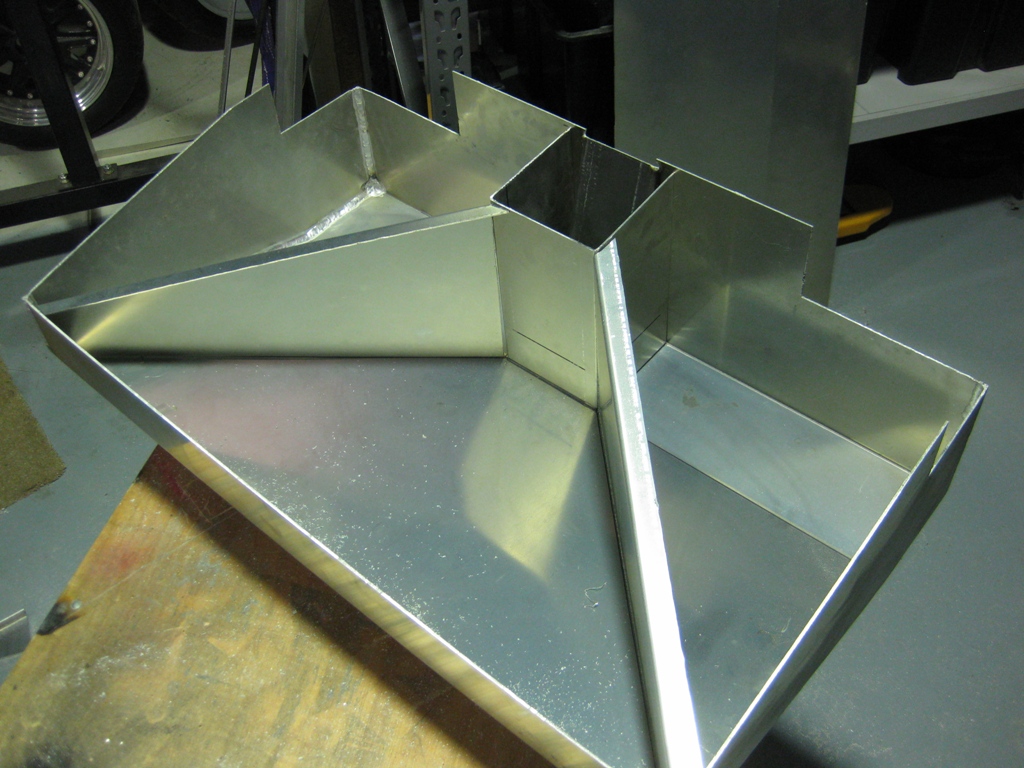

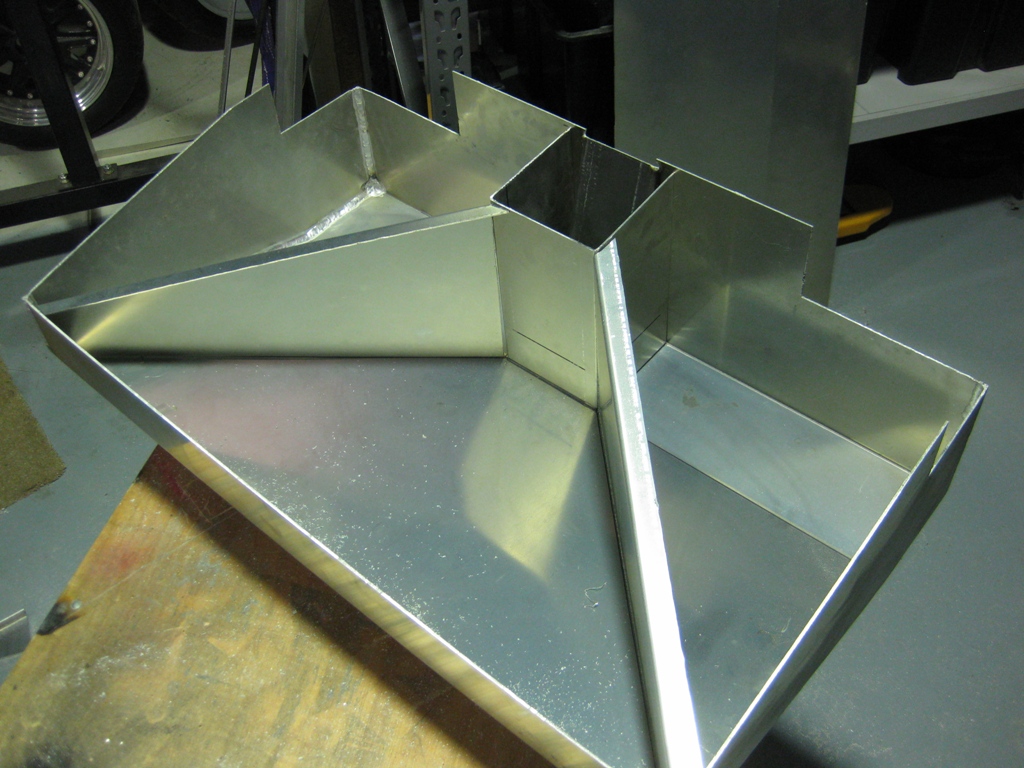

Hi All,

I haven't been working on the car for a long time what with family and work commitments etc. I've finally got stuck back into it. I have to say I'm enjoying working on it.

My current project is to fabricate a new fuel tank and re do most of the fuel system. The original setup is complicated with a lift pump in a donor Commodore main tank feeding a swirl pot which then feeds a big pump for the injectors. It should be possible to do the whole thing with one tank and one pump and do it better.

So the plan is to fabricate a tank with an inbuilt swirl pot and one Bosch 044 pump. I also wanted it to be a better fit for the chassis and look nice from underneath. Also wanted the design to clean up the rear aerodynamics a little. A diffuser Scotty ran at the nationals one year got me thinking about this.

First I made up a pattern out of thin MDF sheet in the profile I wanted. This is a job that's so much easier with a hoist. I bought a sheet of 2.5mm aluminum to make the body of the tank a sheet of 1.6 to make the internal baffles.

With my pattern I marked out the sheet and then used the plasma cutter to slice up the sheet into the right shape. I don't have a guillotine but the plasma cuts aluminum sheet nice and you can use a straight edge to run it along.

Next I took the pieces down to see Chris at Tool Time Engineering. He folded up the basic pieces on their big hydraulic pan brake. If you need any fab work like this done give him a call as they do some awesome stuff in stainless, alloy etc. They have nice CNC press brakes and guillotines and their welders are first rate. Give Chris a call on 0411047775.

The car originally had a donor VN Commodore tank which worked OK but wasn't very pretty and a bit asymmetrical when you looked at it from the back. The new tank is built to fit in the space available.

I'm also not keen on seeing the tank hanging down at the back. This looks good on a Bathurst A9X Torana with a drop tank but not my cup of tea on a Cobra. The new tank is tucked up out of sight under the back.

The new tank should have plenty of capacity but still try to keep the weight centralized by having the bulk of the fuel volume closer to the rear axle. The slope upwards will also work with the removable diffuser.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 04-11-2011 at 11:12 PM..

|

-

Advertising

04-11-2011, 11:39 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Redland Bay,

QLD

Cobra Make, Engine: Harrison #100 under construction

Posts: 1,109

|

|

Not Ranked

Not Ranked

That looks magic Mike. I'm getting close to doing my tank as well so this thread has given me an idea or two-so thanks

Rog

__________________

Rog 246

Harrison #100

|

04-12-2011, 12:13 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Thanks Rog,

I'll keep you posted as I progress.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-12-2011, 03:08 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

Nice work Mike,

Looking forward to the finished product. I love custom fab work.

|

04-13-2011, 03:49 AM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Melbourne,

Vic

Cobra Make, Engine: Harrison, VE L98 + T56

Posts: 164

|

|

Not Ranked

Not Ranked

Weren't you thinking of stainless Mike? What changed you mind?

__________________

Life is what happens to you while you're busy making other plans...JWL

|

04-13-2011, 03:58 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

After doing mine in stainless i would probably recommend Alloy. Stainless warps really bad and is a bugger to polish.

|

04-13-2011, 04:21 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Charlottesville,

va

Cobra Make, Engine: Coombe, Shelby Block 496

Posts: 1,187

|

|

Not Ranked

Not Ranked

Tank looks nice, but why step down to 1.6 for the baffles?

|

04-13-2011, 04:53 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I went with alloy because I figured machining up all the fittings to weld to it would be a pain in stainless. Much more stuff available in aluminum in that department.

Usually when I buy materials like aluminum bar stock and sheet I buy extra because I know I'm going to use it in the future. I bought a couple of sheets of 2.5mm and a sheet of 1.6mm. I figured the baffles are only containing the fuel movement and adding a bit of bracing so don't need to be so thick and add extra weight. There will be quite a bit of baffling inside.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-13-2011, 05:13 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Charlottesville,

va

Cobra Make, Engine: Coombe, Shelby Block 496

Posts: 1,187

|

|

Not Ranked

Not Ranked

I would use the 2.5 for the baffles as well, I have seen lots of tanks baffles come loose.

The 2.5 will all so weld better with less distortion.

|

04-13-2011, 05:22 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

Provided they are welded properly, 1.6 will be fine for baffles. If you have seen them come loose its likely they were not welded properly.

If the tank is 75ltrs, then the mass of the fuel is around 55kgs. If there is 2 baffles then there is 18kgs in each section when full. You will have to go around a corner pretty damn fast for that to rip 1.6mm apart, especially when it is welded on 3 or all 4 sides.

Mike not sure what your plan is but folding the edges of the baffles and welding them flat against the sides and bottom works well.

|

04-13-2011, 05:37 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Charlottesville,

va

Cobra Make, Engine: Coombe, Shelby Block 496

Posts: 1,187

|

|

Not Ranked

Not Ranked

Well I could be thinking over kill I guess, we would never go less than 2.5 on all our race boats and car tanks, never had a problem with them but sure was asked to look at repairing a few others.

1.6 may be fine with some shape in the baffles

Last edited by cobrakiwi; 04-13-2011 at 05:39 AM..

|

04-13-2011, 05:39 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Redland Bay,

QLD

Cobra Make, Engine: Harrison #100 under construction

Posts: 1,109

|

|

Not Ranked

Not Ranked

Look this just has to said okay......

I was initially baffled at 1st,........... but now,..... this just makes sense !!

__________________

Rog 246

Harrison #100

|

04-13-2011, 05:54 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cobrakiwi

Well I could be thinking over kill I guess, we would never go less than 2.5 on all our race boats and car tanks, never had a problem with them but sure was asked to look at repairing a few others.

1.6 may be fine with some shape in the baffles

|

Yes the design will make a big difference. If they are butt welded they would be more likely to tear as the weld will be in the higher stress area. The heat of welding may also affect that area. |

04-24-2011, 05:58 PM

|

|

CC Member

|

|

|

Join Date: Feb 2011

Location: The Hills,

NSW

Cobra Make, Engine: have brakes, diff, gearbox, steering rack, gear stick, door locks, CR chassis 3518

Posts: 91

|

|

Not Ranked

Not Ranked

Came across these fuel level sender units, available in a number of different lengths, maybe useful to someone out there.

Sensor Gauge Accessory by SpeedHut |

08-12-2011, 07:43 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Finally got back to doing some work on the car. It's a good feeling to be working on it again. Got to get cracking and get it on the road again for Summer.

Made a bit more progress on the new fuel tank.

Here are the baffles roughly worked out and the swirl pot. I made a bit of a mistake when folding the stiffening edge on the baffles and folded them both the same way. Doesn't matter as no one will see them and it won't affect how they work.

The tank is welded inside and out as I want to avoid any leaks from pinholes if possible.

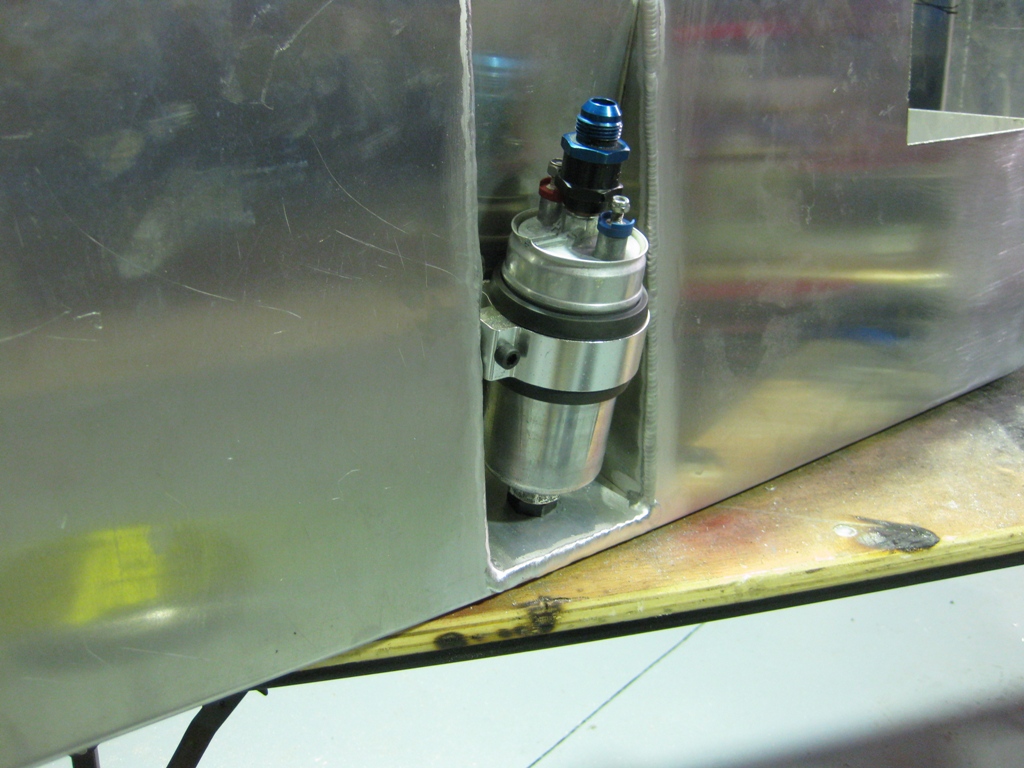

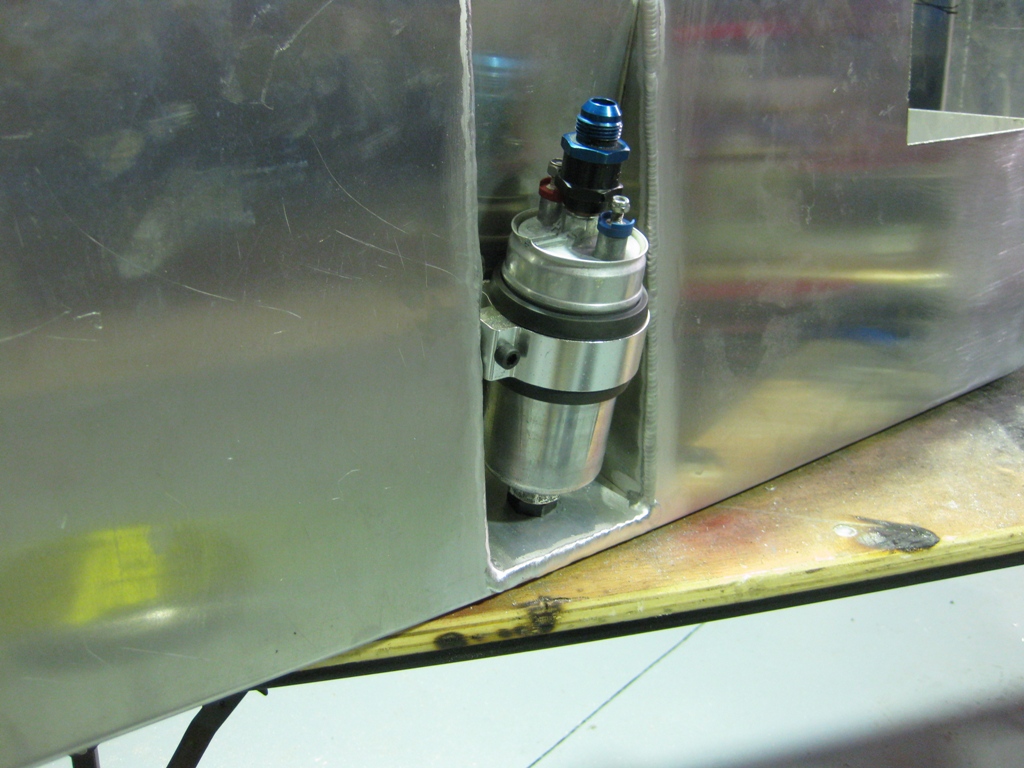

Here's the Fuel pump setup. I'm rather proud of this. It lets me keep my external Bosch 044 pump but it picks up fuel from the bottom of the tank right in the swirl pot like an in tank pump. I was never keen on running wiring inside the tank or fabricating some way of getting the wiring in there.

The bracket and fittings are all integrated into the tank. You just screw the pump into place. Makes it easy to service or replace.

Next step is to finish the swirl pot and weld the baffles in. I'm machining up trap doors for the swirl pot at the moment.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-12-2011, 05:29 PM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Cheltenham,

Vic

Cobra Make, Engine: Classic Revival CR3516, LS3, Aussie Mike'd T-56, 3.70 LSD, AP brakes, Penske shocks

Posts: 1,616

|

|

Not Ranked

Not Ranked

as usual Mike, a work of art

__________________

BUILD-BLOG: http://cobrablog.holnet.net

Ben in AU

|

08-12-2011, 09:55 PM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

Looking good Mikey!

__________________

Powered by Cu

|

08-12-2011, 10:22 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

You should start your own construction company Mike. Lots of people would like your designs!

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

08-13-2011, 10:01 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2008

Location: McAllen,

TX

Cobra Make, Engine: Butler...488" hi-rise, dry-sump FE s/o w/stacks

Posts: 543

|

|

Not Ranked

Not Ranked

Beautiful design and fabrication....waiting impatiently for the "trap door" design and pics.

__________________

Russ

|

08-14-2011, 05:49 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Thanks for the encouragement.

Nearly got the swirl pot finished today. Just got to weld it and the baffles in.

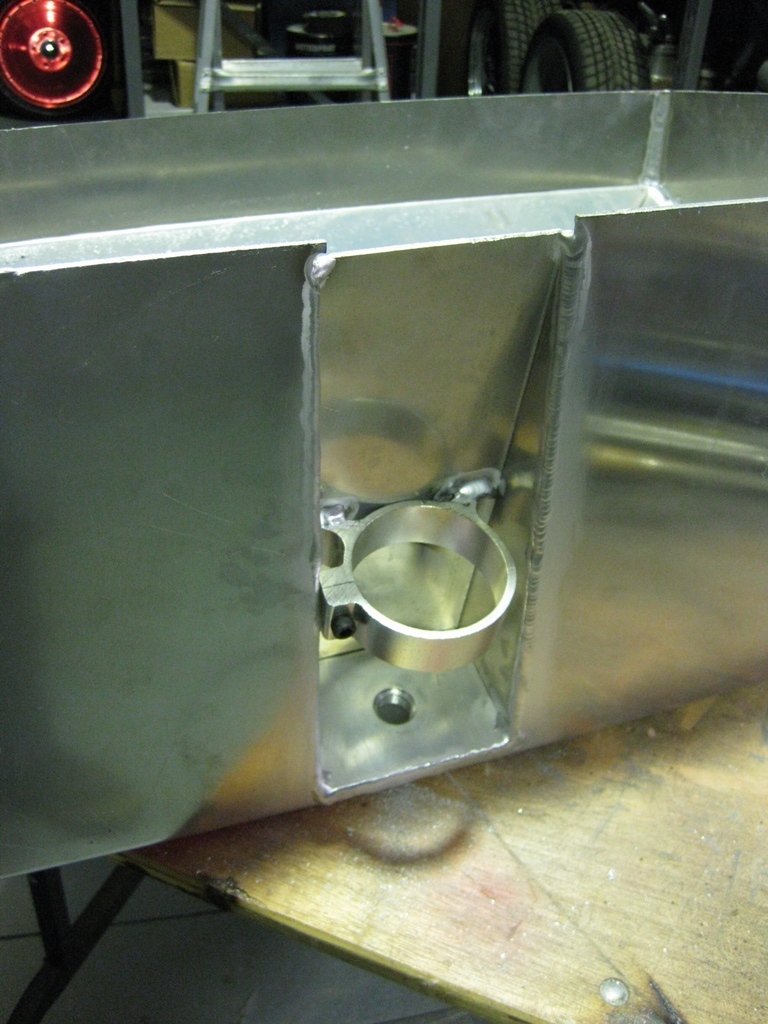

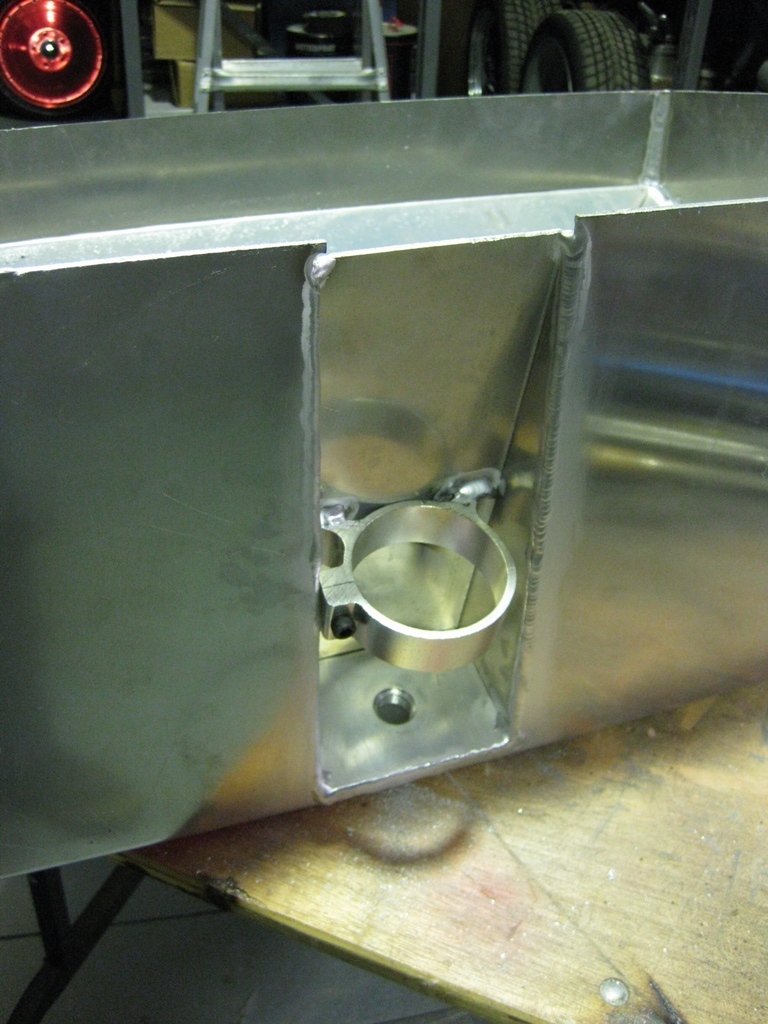

Here's some detail on the fuel trap doors in the swirl pot section.

In this pic you can see the opening in the bottom of the swirl pot. Under braking fuel will be pushed forward and flow into the swirl pot from the rear section of the tank. The baffles help direct the fuel towards the inlet.

Inside the swirl pot the trap doors look like this.

The trap doors pivot on pins through the sides. The weight of fuel should keep it shut but I figured with all the bumps and cornering forces I wanted a way to keep it closed unless there was a flow of fuel incoming against it. I thought of using light springs to provide a positive way of keeping the trap door closed but springs aren't reliable. I set them up with counter weights in the form of the long screws tapped into the top of the hinge. These are set in pointing down on an angle. Gravity keeps the trap door shut and you need to tip it on a near 45 degree angle before it opens on it's own.

The counter weight work against the braking, acceleration and cornering forces. The trap door in the back when under acceleration the counter weights (The end being below the pivot point) clamp the trap door shut. While under breaking being they help swing the trap door open. In a corner the trap doors on the sides of the swirl pot work the same way. The door on the outside of the turn clamps shut while the inside one swings open helping the fuel from that section of the tank to flow into the swirl pot.

I guess it's not really a swirl pot and probably better described as a surge tank.

That's the theory, It's been fun to make and hopefully it'll work like I reckon. Holding the surge tank and spinning around on a stool while watching the trap doors has been the only testing so far

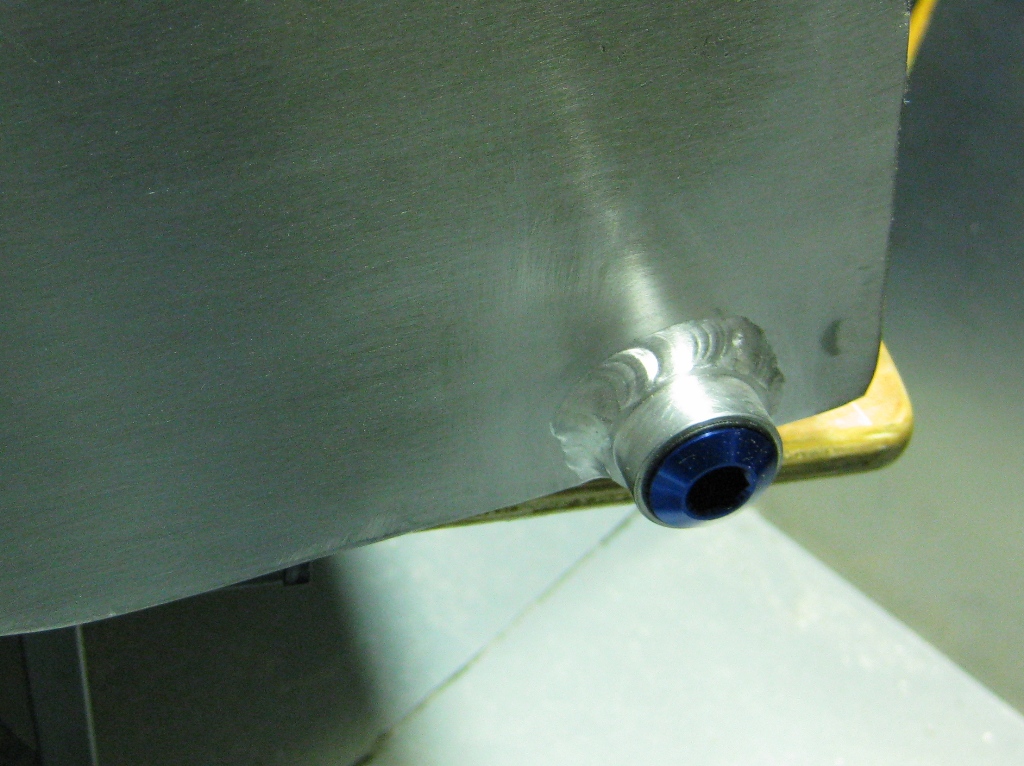

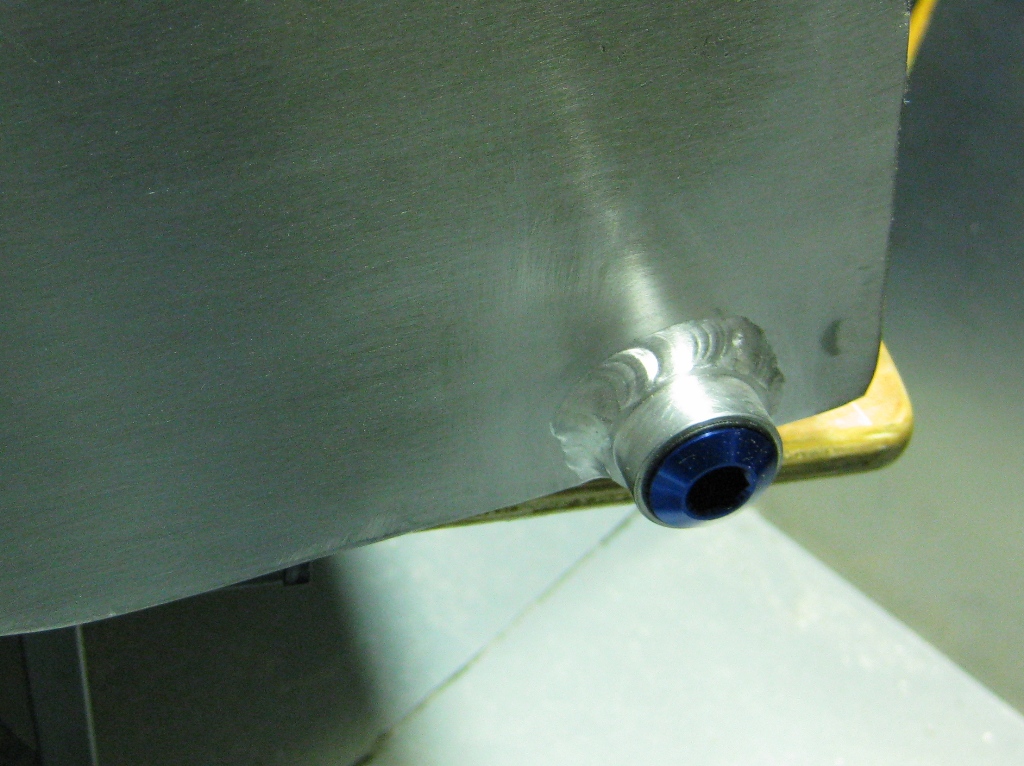

The other thing I've done is add a drain port to the tank. I figured it'd be useful to have an easy way to drop the fuel out of the tank especially if the car sits for a long time.

This pic also gives an idea of the finish I'm going for. The welds were nice but I wanted the tank to look like it was made from one piece so I've ground back the welds and rounded the corners. I like the look of the brushed finish on the Kirkhams and figure a brushed finish will look nice while hiding any scratches etc from dirt and stones under the car.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:47 AM.

|

|

Linear Mode

Linear Mode