Hi All,

Just a quick update on this. Turns out I was given the wrong dimensions on the clutch

. Here I am struggling to find the needed clearance and it turns out you only need to take 5 or 6mm off to fit it in.

Sorry folks if I've given you a bum steer in my previous posts. This is now the correct info.

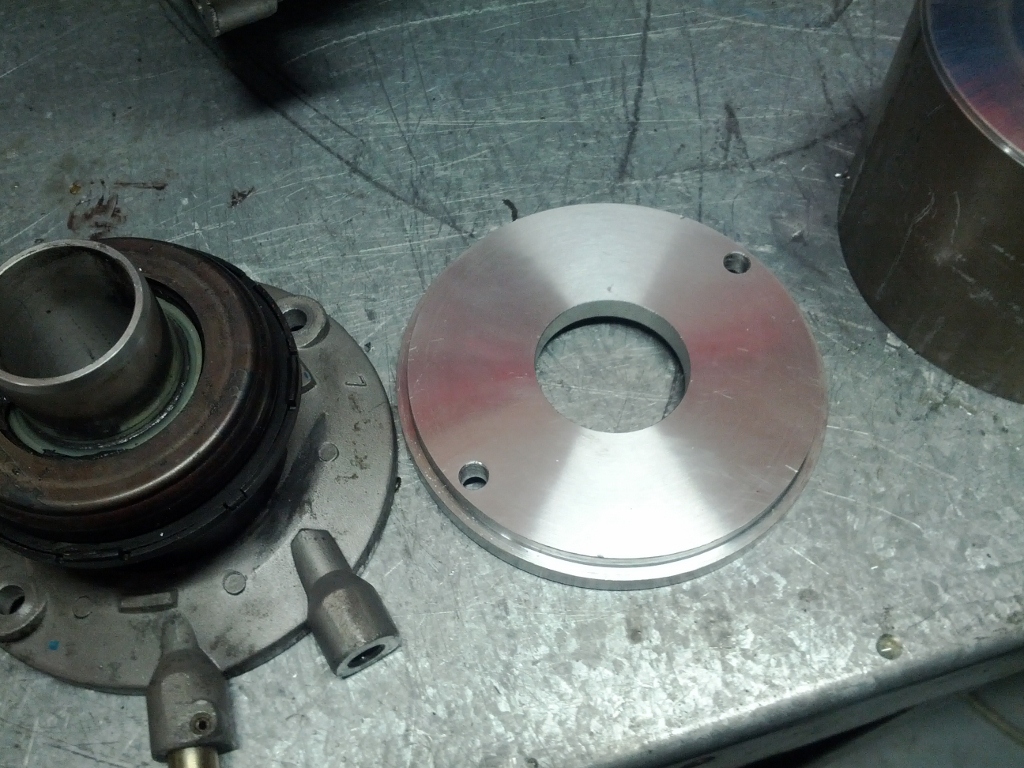

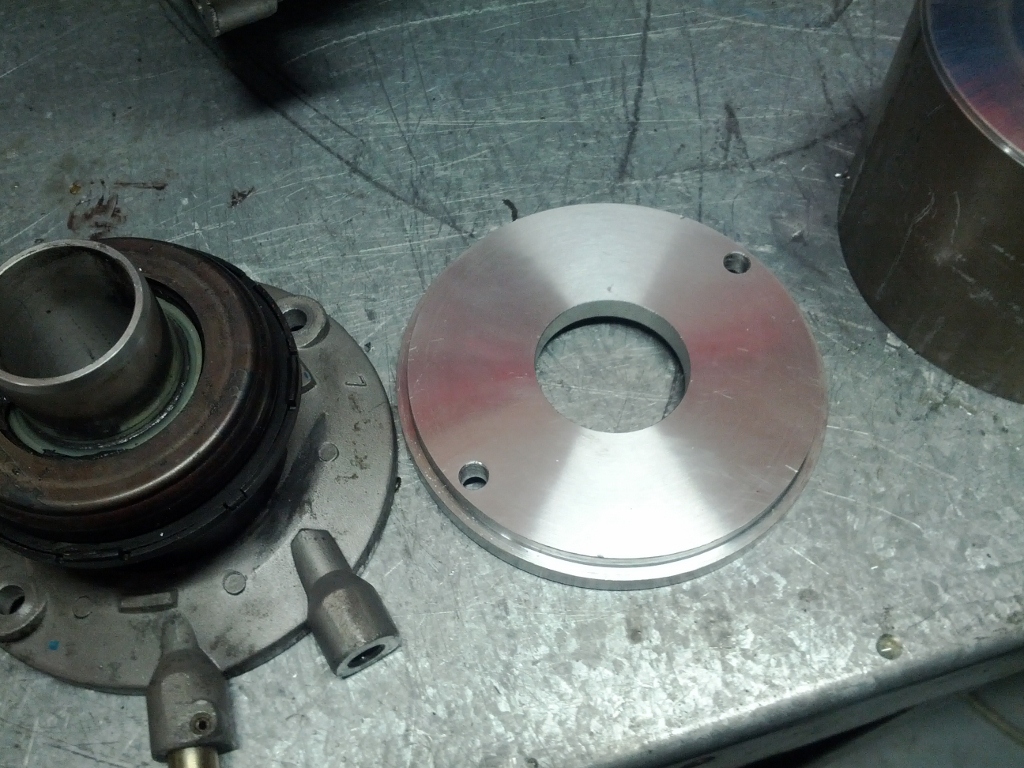

Now I've got to get this box back to the right dimensions so a spacer is needed. Here's a 9mm thick spacer I machined to bring the slave out to the right position.

The spacer is machined with register rings on the back and the front to hold it central.

All fixed.

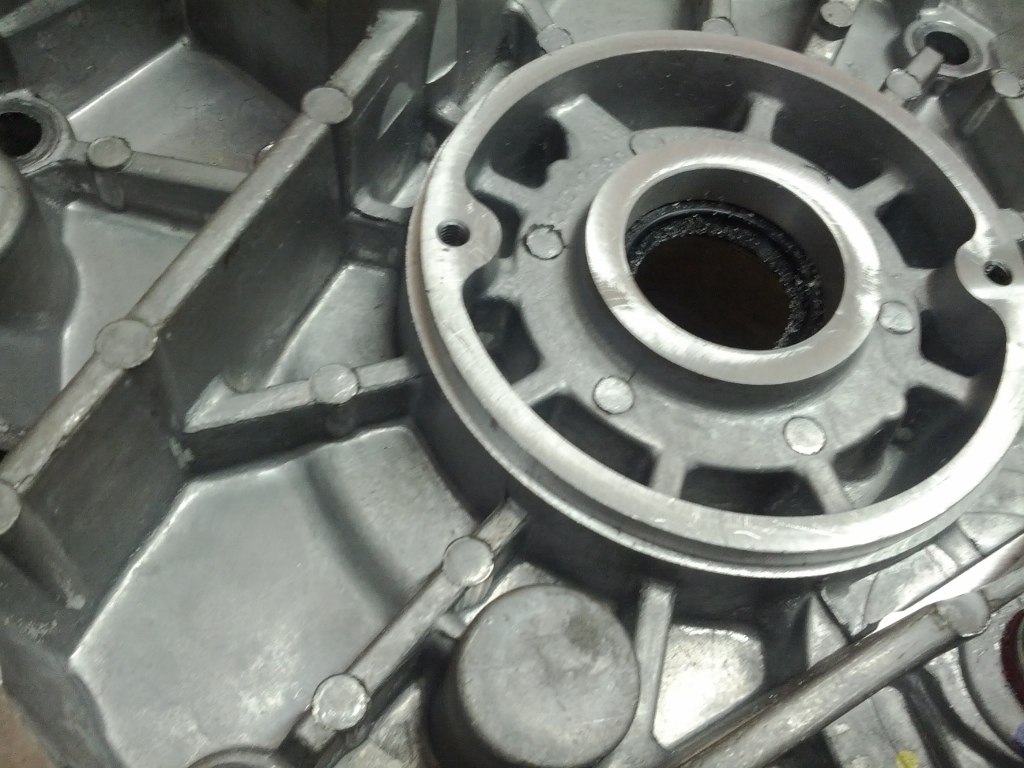

Here's one I've machined to the right dimensions.

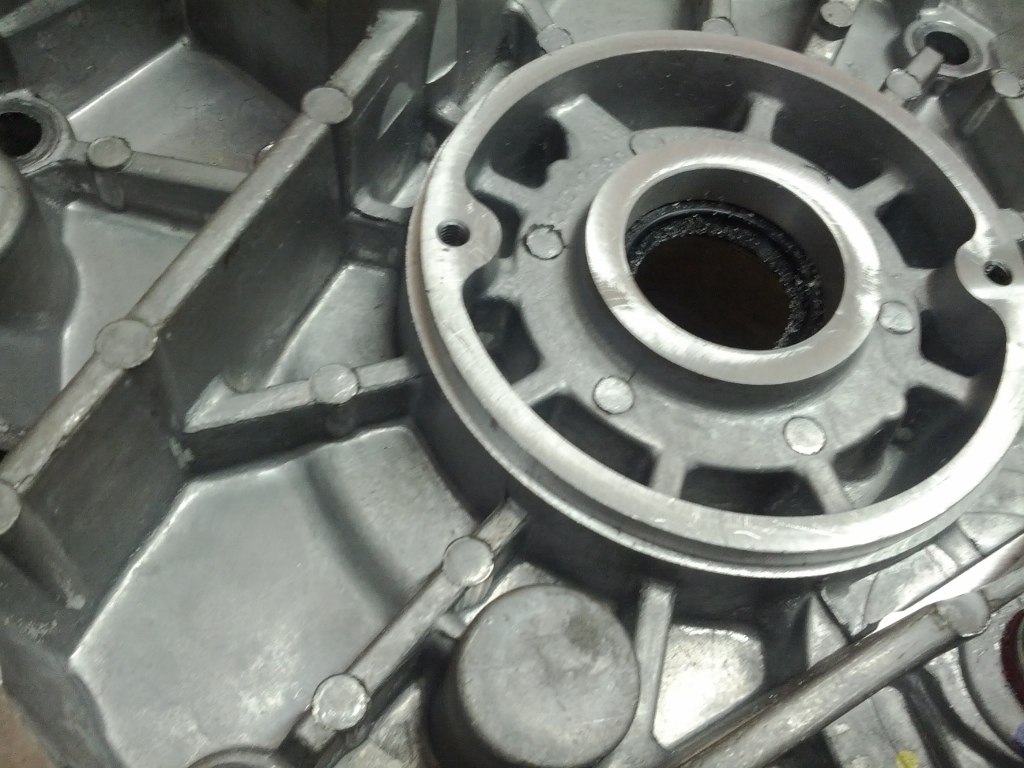

Unfortunately not a job that can be done on an assembled box but you can unbolt and remove the front plate if you are careful without disassembling the rest of the box. It can then be machined to size but you will need to know what you are doing to get it back together..

Half the difficulty in machining this is working out a way to hold the piece to machine it. In fact that's a big part of the challenge in any machining operation is working out how to position and grip the workpiece. The machining only takes a few minutes, it's the setup that takes time. To make life easier when machining these I machined up a collet. This slips inside the socket for the front bearing race and lets me grip the piece from there. The collet has 360 degree contact and holds the plate securely and keeps it square. It also protects the race from dammage by the hard steel jaws of the chuck.

Cheers

. Here I am struggling to find the needed clearance and it turns out you only need to take 5 or 6mm off to fit it in.

. Here I am struggling to find the needed clearance and it turns out you only need to take 5 or 6mm off to fit it in.

Linear Mode

Linear Mode