Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

7Likes 7Likes

04-02-2012, 02:57 AM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Retro engineering a t56 gear lever (shifter)

Retro engineering a t56 gear lever (shifter)

I’m hoping to create a 250 GTO gear shift casing (see photo). Fabrication should not be a problem.

At present, at the height of the gate, the lever moves on the ‘y’ axis about 70 mm, eg. between 1st and 2nd which is okay, however, there is only 7mm between each gate on the ‘x’ axis. Considering the diameter of the shifter it is impossible to recreate the fingers pattern of the original GTO.

Any thoughts on how I can get this to work?

I know the t56 is used in a lot of applications, even Aston Martins, so I'm wondering if anyone has come across a car fitted with a t56 that has a suitable gate pattern. Thanks.

|

-

Advertising

04-02-2012, 05:46 AM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Newcastle, Warners Bay,

NSW

Cobra Make, Engine: RMC . 393 Dart alloy block Stroked 351 alloy heads ..all the goodies plus a pre oiler. al

Posts: 1,495

|

|

Not Ranked

Not Ranked

If you make the shift gate closer to the top of the box the distance between gear positions should be closer....you'll need to do a lot of trial fitting. Maybe; Make a template of the gate and move it up and down until you find a sweet spot.

Fit the template on thread-bar studs and adjust it up and down to find the spot.

Just a thought.

|

04-02-2012, 07:35 AM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Rob - Thanks. Unfortunately the sideways movement is very minimal and I think I would have to have the gate just about touching the gear knob to get enough for the pattern.

|

04-02-2012, 04:45 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Location: Gold Coast,

AUS

Cobra Make, Engine: Wish I had my own PACE 427

Posts: 2,145

|

|

Not Ranked

Not Ranked

Peter, how much difference does it make if you run a thinner gearstick shaft?

|

04-02-2012, 05:17 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

That was going to be my suggestion Craig.

Peter, if your using the B&M shifter they are fairly chunky, you may need to get something machined up using Stainless or similar strong metal to achieve a thinner stick?

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

04-02-2012, 07:32 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Location: Gold Coast,

AUS

Cobra Make, Engine: Wish I had my own PACE 427

Posts: 2,145

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by boxhead

That was going to be my suggestion Craig.

Peter, if your using the B&M shifter they are fairly chunky, you may need to get something machined up using Stainless or similar strong metal to achieve a thinner stick?

|

Normally I am one step behind you Boxhead.  It's nice to be one step ahead for a change. You did give more information with shifter shaft strength, stainless would be a nice way to go. |

04-02-2012, 10:24 PM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 400TT

Peter, how much difference does it make if you run a thinner gearstick shaft?

|

Craig et al. - I would have to use a 5mm dia shifter to get 2mm 'fingers' and that's with no clearance, even then the appearance of the gate would be ruined.

Others have thought along these lines but apparently got nowhere: Ferrari Style Shift Plate - Third Generation F-Body Message Boards

I'll give Mal Woods a call and see if he knows of a production car which has such a set up. |

04-03-2012, 12:29 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

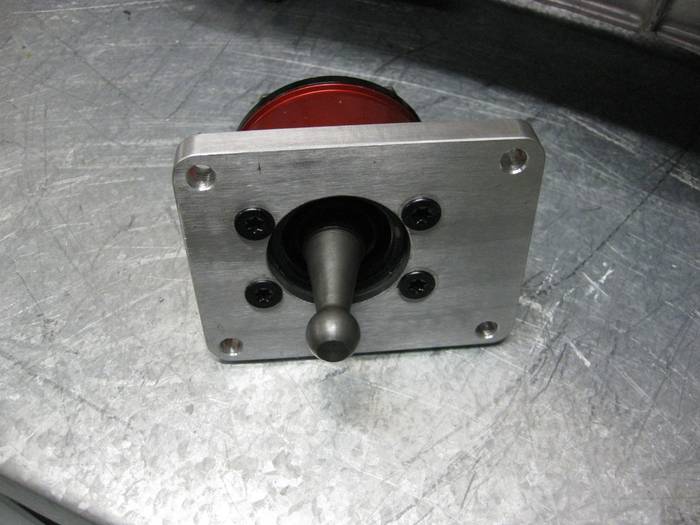

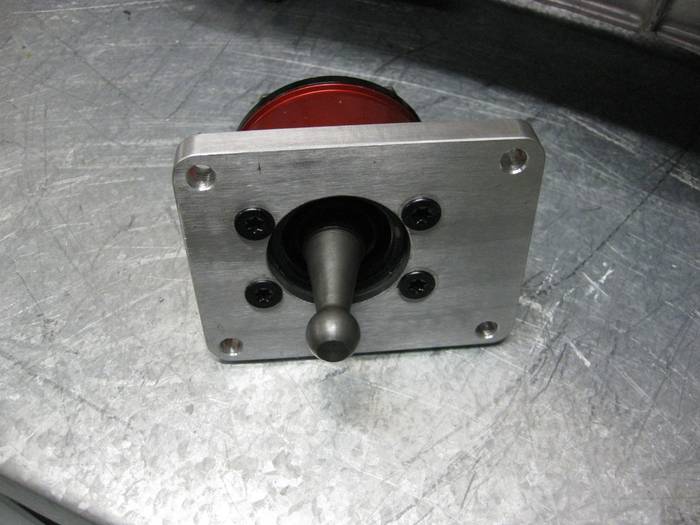

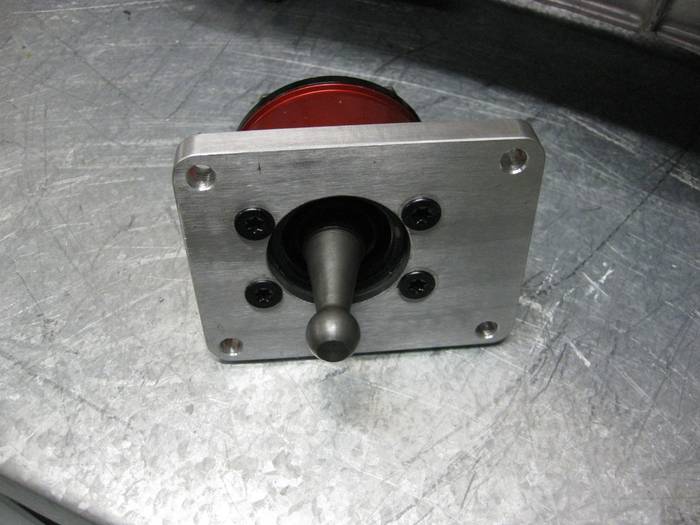

You just need to change the pivot ratio in the shifter itself to give you more movement at the lever. I do this a bit with my mid shift conversions.

The first question to ask is are you using the stock shifter location or a mid shift setup? This will help with working out getting a better ratio on your shifter. In the stock position there's probably a bit more room to move.

Stock location opens up more possibilities for changing the ratio.

The shifter ratio is going to be the distance from the center of the ball it pivots on to where the tip contacts the sides of the socket on the selector rail.

Most after market shifter I've seen these days are set up for short throws so this distance is quite long. Howver they usually leave a fair bit of clearance at the bottom of the socket. I like to drop the shifter further into the socket as I'm not that keen on the short throw shifts these days. Dropping it in gives you a little more side to side but the same forwards and back.

Here's a mid shift shifter I've re machined to drop it further in. This only gains you a little bit though and probably not what you are looking for.

What you really want to look at is shortening up that distance between the pivot and the ball on the end of the shifter and then dropping it in to retain the right position in the socket. You may be able to adapt another shifter with a better ratio or if you are handy on the lathe you could machine up a new shaft with the ball in the right spot to give you your ideal ratio.

Some of the B&M Shifters use a hard nylon pivot ball that slips over the rod and is held in place with a dowel pin. you could weld up and redrill the dowel hole a bit further down and change the ratio.

The other option that only works with the stock position is to remove the socket from the shifter rail. Cut it off and re weld it on further down and then machine the shifter base to drop it down accordingly. This would change your ratio and probably the easiest way I can think of.

Just some ideas.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 04-03-2012 at 12:35 AM..

|

04-03-2012, 01:46 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

Yeah, just like I was thinking Mike.

__________________

Powered by Cu

|

04-03-2012, 04:59 AM

|

|

CC Member

|

|

|

Join Date: Nov 2004

Location: Sydney,

NSW

Cobra Make, Engine: Classic Revival #3199. 366ci L76, T56 6 speed, Blue circle custom paint, Australias most original cobra 2009-2010

Posts: 2,396

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Aussie Mike

You just need to change the pivot ratio in the shifter itself to give you more movement at the lever. I do this a bit with my mid shift conversions.

The first question to ask is are you using the stock shifter location or a mid shift setup? This will help with working out getting a better ratio on your shifter. In the stock position there's probably a bit more room to move.

Stock location opens up more possibilities for changing the ratio.

The shifter ratio is going to be the distance from the center of the ball it pivots on to where the tip contacts the sides of the socket on the selector rail.

Most after market shifter I've seen these days are set up for short throws so this distance is quite long. Howver they usually leave a fair bit of clearance at the bottom of the socket. I like to drop the shifter further into the socket as I'm not that keen on the short throw shifts these days. Dropping it in gives you a little more side to side but the same forwards and back.

Here's a mid shift shifter I've re machined to drop it further in. This only gains you a little bit though and probably not what you are looking for.

What you really want to look at is shortening up that distance between the pivot and the ball on the end of the shifter and then dropping it in to retain the right position in the socket. You may be able to adapt another shifter with a better ratio or if you are handy on the lathe you could machine up a new shaft with the ball in the right spot to give you your ideal ratio.

Some of the B&M Shifters use a hard nylon pivot ball that slips over the rod and is held in place with a dowel pin. you could weld up and redrill the dowel hole a bit further down and change the ratio.

The other option that only works with the stock position is to remove the socket from the shifter rail. Cut it off and re weld it on further down and then machine the shifter base to drop it down accordingly. This would change your ratio and probably the easiest way I can think of.

Just some ideas.

Cheers |

Yeah.....What he said.

(Only problem is if you double the throw left and right, you'll also double the throw for and aft. So if the 7 becomes 14, the 70 will become 140). I was thinking of some sort of hinge in the shifter below the ferrari gate and above the pivot pt. with a limited movement left and right - but the more I thought about it the more I thought it probably wouldnt work and would make the shift feel stirring a bucket of poo with a chop stick.

__________________

Proudly registered since 2013.

|

04-03-2012, 06:14 AM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Newcastle, Warners Bay,

NSW

Cobra Make, Engine: RMC . 393 Dart alloy block Stroked 351 alloy heads ..all the goodies plus a pre oiler. al

Posts: 1,495

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PeterAllen

Rob - Thanks. Unfortunately the sideways movement is very minimal and I think I would have to have the gate just about touching the gear knob to get enough for the pattern.

|

No the closer you go to the gear knob the wider the spread of travel...you have to go closer to the gearbox/shift base. Instead of using a genuine Ferrari pattern you should make a similar one to suit your set-up. |

04-03-2012, 07:21 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Tenrocca

Yeah.....What he said.

(Only problem is if you double the throw left and right, you'll also double the throw for and aft. So if the 7 becomes 14, the 70 will become 140). I was thinking of some sort of hinge in the shifter below the ferrari gate and above the pivot pt. with a limited movement left and right - but the more I thought about it the more I thought it probably wouldnt work and would make the shift feel stirring a bucket of poo with a chop stick.

|

That may work Andrew. The stock Commodore remote shifter uses something similar. You could play with the ratios that way. As long as you keep all the tolerances tight it shouldn't slop. Besides he will have the H gate on top of it to keep it from sloping around.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-03-2012, 06:35 PM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Mike - I'm using the rear/standard shifter location.

Even with a modified remote I can't see how I can change one ratio without changing the other?

I also thought of the 'hinge' concept and it would probably work on a 3-4 speed box but not on a 6 speed unless it incorporated some spring self-centring arrangement.

|

04-03-2012, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

No you can't really change one without changing the other with that setup. However you the extra throw might be acceptable for the right side to side clearance. I would look at raising the pivot point on the front of that linkage to see if you get enough extra movement out of it. It shouldn't be hard to weld a piece on and re drill it.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

04-03-2012, 08:09 PM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

I wonder if I utilise two 'load' points, one for backwards and forwards and one for side to side.

On the beer coaster design below the arrows indicate where there would be no force transmitted. The additional 'contact' a shorter distance from the fulcrum should mean I now have to move the gear knob further left and right to match the current shaft movement whilst not changing the backward/forward movement. Comments please.

Last edited by PeterAllen; 04-03-2012 at 08:27 PM..

|

04-04-2012, 04:07 AM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Oops! Just been looking a bit closer at the box and discovered the selector shaft rotates (approx 15 degrees) rather than moviing left and right when shifting from 1-2 to 3-4 and 5-6.

Back to the pub for some more creative thinking.

|

04-06-2012, 10:26 PM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Plan B.

Very optimistic I have something that will work but I need to modify a t56 shifter cup - also referred to as a shifter socket or offset lever (see photos). Does anyone have one they would like to sell?

I think some owners may have replaced the longer Commodore one with the shorter one from an F-body, if they have used an after-market shifter.

It doesn't matter which one, either will do. Thanks

Last edited by PeterAllen; 04-08-2012 at 04:12 AM..

|

01-18-2015, 02:34 AM

|

|

CC Member

|

|

|

Join Date: Jul 2011

Location: Sydney,

NSW

Cobra Make, Engine: Puckett 250 GTO - LS1

Posts: 567

|

|

Not Ranked

Not Ranked

Some of you builders may be aware of this but I have discovered that leaving a problem for over two years doesn't make it go away.

I'm working on plan 'F' but I still need a cup/socket. Does anyone have one lying around? Doesn't matter F-body or Commodore. Thanks

|

01-18-2015, 03:52 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I found one the other day. PM me your address and I'll post it to you.

Cheers

Mike

__________________

Mike Murphy

Melbourne Australia

|

01-19-2015, 05:56 PM

|

|

CC Member

|

|

|

Join Date: Apr 2011

Location: Orange,

NSW

Cobra Make, Engine: Dax

Posts: 429

|

|

Not Ranked

Not Ranked

I got a rough one from the scrappie the other day too, let me know if you want it.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:55 AM.

|

|

7Likes

7Likes

It's nice to be one step ahead for a change. You did give more information with shifter shaft strength, stainless would be a nice way to go.

It's nice to be one step ahead for a change. You did give more information with shifter shaft strength, stainless would be a nice way to go.

Linear Mode

Linear Mode