Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

7Likes 7Likes

11-01-2012, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

One good looking donk for another!

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

-

Advertising

11-01-2012, 05:53 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Location: Gold Coast Queensland,

QLD

Cobra Make, Engine: Harrison#97 LS7 / T56

Posts: 1,682

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by spookypt

Merv, AC005 did the engine swap as that particular 347 had been polished to death by its urrrr previous owner! I believe it had excessive "external" wear and tear from the microfibre rub!

|

My "polish knuckles" have all healed up now.....ready to start polishing the NEW car.....not long now! |

11-01-2012, 09:53 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Cobra Make, Engine:

Posts: 2,752

|

|

Not Ranked

Not Ranked

cobra

cobra

I'm hearing its gonna be one hell of a car wazza. Cant wait to see it.

Now back on topics......

Engines....hmmmm

|

11-01-2012, 10:15 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Spook, for some reason I thought you were running a big block in that Backdraft. Can you tell us a bit more about the combination you are running?

Cheers

__________________

Mike Murphy

Melbourne Australia

|

11-01-2012, 11:05 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Cobra Make, Engine:

Posts: 2,752

|

|

Not Ranked

Not Ranked

351w

351w

Hi Mike, you've got me thinking I might start a thread on my particular car if there is interest as some may find it interesting being from the USA/Sth Africa. But seeing as though where in the topic of engines....

I generally tell people its a smokey ole 351w windsor but between you and me..

Here's some light reading...

The engine is a 351w (372 cube) Dart Iron Eagle 9.2 deck 302 mains.

Sonny Bryant Steel Crank 3.450 Stroke Nascar Crankshaft

Eagle Steel H Beam Rods

Comp Cams Custom Crankshaft Grind 318DR-12

Edelbrock 2929 9.2 Super Victor Intake Manifold

4 stage Dry sump

960cfm proform Carb

Dual MSD

13.5:1 Compression running 112-116 Leaded Sunoco Supreme Race fuel

The bits list goes on and on...

The engine will turn to 9200rpm with that combo but is currently rev limited to 8000rpm to increase durability where possible.

The engine was built and refreshed in the USA prior to being sent to me... After a full USA engine rebuild/refresh..... I did a oil filter inspection after its

1st outing and found it was eating Valve Stem Seals...

So my new car/engine is off to my engine builder for an open chested inspection.

(If you've just bought an engine from the States don't read any further)

On removal of tappet covers we discovered the roller rockers had all been rubbing on their retainers, some attempt had been made to clearance rocker to retainer but it was insufficient. The valve stem seal problem was attributed to the fact that the valve stem seal area of the valve guide had been machined down to .480”, our guess is, to fit a smaller o.d. seal to clear the triple valve springs. The problem with doing this was - the grooves on the valve guides that grip the seals was machined off allowing the seals to

slide off very easily. Using the correct small o.d. seals on the original .530” o.d. valve guide would have saved this whole problem, and in fact given more seal to spring clearance than the seals that were used.

Another issue we found with the cylinder heads was the helicoils to hold the rocker stands. These were very loose in the heads and some had no parent thread left or very little. To correct this we drilled and tapped the

heads to 3/4 unc, screwed in some 4340 slugs and drilled and tapped to 7/16 unc. We reckon the side load caused by rockers to retainers caused this problem.

Now on further inspection we found the bottom end also had problems - firstly bottoms of the bores were not chamfered causing piston skirts to scrape, so we chamfered bores and coated pistons.

Secondly, the middle cam bearing was in very bad condition, which was easily explained by the fact

oil restrictors were fitted to restrict oil flow to cam bearings , all fine except the plug in the middle gallery had "no hole in it", thus the bearing was receiving no oil under pressure.

The block surface finish was far too coarse for the MLS Gaskets used and required refinishing. There was crankshaft damage to the webbing that had been dressed up so we feel it had obviously been in another engine that had failed. The marks in the journals would also suggest the crank had been

polished leaving valleys and no peaks and the crank needed grinding.

Lastly for a high performance engine there was no port matching in the manifold – even though it is not a fault as such, the manifold should have been match ported to heads particularly on a build like this, no point having CNC ports when the manifold only creates dead areas in ports.

So, I'd suggest the engine "insert appropriate name here" went out and bought the best parts he could find and the proceeded to WallMart for a 6 pack of Buds and a few blue tarps to set up in the backyard and build MY ENGINE.

On discussions with my US friends the above issues were not covered by warranty as IT'S A RACE ENGINE!!!!

On top of all that the metal bits lunched my dry sump pump as no inlign filters were used. Order up!!!!!

That all being said I did get some fiscal recourse through the cars manufacturer which was better than a kick in the mellon.

Its a stout engine but it will never be stretched enough by me to appreciate its full potential.

Spookypt

|

11-01-2012, 11:52 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

A great Friday arvo read there Spook - thanks

Good luck with the rebuild |

11-02-2012, 12:13 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Interesting stuff Spook. It looks like a good selection of parts, just badly put together.

The NASCAR boys are restricted to 358 cubes with a 4.185" max bore. That means a 3.253" stroke. They pull 10,000 RPM all day with the shorter stroke.

I've read about changing to 302 mains on 351 motors. The standard 351W has big main journals which makes for a strong crank but they don't survive when reving hard.

The reason is oil shear. When the crank rotates in it's journal there is a film of oil in there keeping the two surfaces apart. Under extreme mechanical strain the oil will lose it's viscosity and cease to keep those surfaces apart. The larger journal means the oil is having to travel faster for the RPM's the motor is running. Switching to a smaller journal slows the oil movement and lets the motor rev harder before the oil loses viscosity.

I believe this is one of the reasons why the 351C motor was a better rever than the 351W because it has smaller main journals (and fricken huge ports).

__________________

Mike Murphy

Melbourne Australia

|

11-02-2012, 12:37 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Cobra Make, Engine:

Posts: 2,752

|

|

Not Ranked

Not Ranked

351w

351w

Interesting Mike.... Once this engine has its day (not for while I hope) I won't go back to this combo I don't think. The fellow that built my car (Reg Dodd) has a background in high reving engines (2 strokes) so this was his preference. If its changes so does GBox ratios and rear end ratios as well.

|

11-02-2012, 01:21 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: Central Coast,

NSW

Cobra Make, Engine: DRB #145, Ford 5.0 HO

Posts: 227

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ACO05

Hi Adz,

I dropped an Edelbrock crate engine in my DRB in June last year.

The endurashine finish is awesome and so so easy to keep clean.

I live is Cairns to driving through the odd rain shower is common.

Car had a 347 in previously built on a HO block.

Edelbrock did specify I had to use a manual water pump not the CVR electric it was using and also change ICE ignition to MSD as verified rev limited ignition was needed to satisfy 2 year warranty requirements.

90% happy with crate tune, think a holley carby would be easier to tune as the edelbrock only has an external idle adjustment. No external float adjustment on edelbrock carb.

Immediately noticed an improvement on low rev torque and this engine has a very smooth power curve that never seems strained.

Like you I considered switching to a bigger block and cubes but given I only drive the car spiritedly (above 80%) on the odd occasion, a straight swap without any exhaust, clutch etc changes was the right option.

Good price, power and looks.

Edelbrock.com - Crate Engines - Small-Block Ford - Performer RPM 9.9:1 (438 HP & 413 TQ)

Attachment 21330 |

Thanks AC005, I like that a lot, and the efi version looks unreal too....

Edelbrock.com - Crate Engines - Small-Block Ford - Performer RPM XT EFI 9.9:1 (503 HP & 445 TQ)

Edelbrock.com - Crate Engines - Small-Block Ford - Performer RPM XT EFI 9.9:1 (503 HP & 445 TQ)

After readying Spooky's tale about an engine assembled OS, I am staring to lean towards a 347 CUI stroker kit for my existing block, with upgraded cam, heads and a mass flo efi set up.

I can then change to a standard rotation WP and hook up a gilmer, or maybe even go electric on the WP.

This will sort out recertification of engine dramas and engine number changes,

But I will do the sums, and a bit more research this time, and look to cover all the bases.

Thanks for the link.

Adam

Last edited by ICETOO; 11-02-2012 at 01:24 AM..

|

11-02-2012, 04:59 AM

|

|

CC Member

|

|

|

Join Date: Aug 2008

Location: airlie beach / mackay,

QLD

Cobra Make, Engine: Some kind of FORD thingy, with several pis tins, twin chain driven SUs feeding a Y block, apparently.

Posts: 501

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Aussie Mike

Interesting stuff Spook. It looks like a good selection of parts, just badly put together.

The NASCAR boys are restricted to 358 cubes with a 4.185" max bore. That means a 3.253" stroke. They pull 10,000 RPM all day with the shorter stroke.

I've read about changing to 302 mains on 351 motors. The standard 351W has big main journals which makes for a strong crank but they don't survive when reving hard.

The reason is oil shear. When the crank rotates in it's journal there is a film of oil in there keeping the two surfaces apart. Under extreme mechanical strain the oil will lose it's viscosity and cease to keep those surfaces apart. The larger journal means the oil is having to travel faster for the RPM's the motor is running. Switching to a smaller journal slows the oil movement and lets the motor rev harder before the oil loses viscosity.

I believe this is one of the reasons why the 351C motor was a better rever than the 351W because it has smaller main journals (and fricken huge ports). |

Thats what im running, 302 mains in a 383w stroker, a bit exotic but it just snaps open. The dart iron eagle that spooks got is the ducks guts.

__________________

Nuts,,, Bolts,,, and 2 smoking barrels.

|

11-02-2012, 05:38 AM

|

|

CC Member

|

|

|

Join Date: Aug 2008

Location: airlie beach / mackay,

QLD

Cobra Make, Engine: Some kind of FORD thingy, with several pis tins, twin chain driven SUs feeding a Y block, apparently.

Posts: 501

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ICETOO

Thanks AC005, I like that a lot, and the efi version looks unreal too....

Edelbrock.com - Crate Engines - Small-Block Ford - Performer RPM XT EFI 9.9:1 (503 HP & 445 TQ)

Edelbrock.com - Crate Engines - Small-Block Ford - Performer RPM XT EFI 9.9:1 (503 HP & 445 TQ)

After readying Spooky's tale about an engine assembled OS, I am staring to lean towards a 347 CUI stroker kit for my existing block, with upgraded cam, heads and a mass flo efi set up.

I can then change to a standard rotation WP and hook up a gilmer, or maybe even go electric on the WP.

This will sort out recertification of engine dramas and engine number changes,

But I will do the sums, and a bit more research this time, and look to cover all the bases.

Thanks for the link.

Adam |

Hi Adam, just a piece of advise, im not sure what block youve got, but if youre going to stroke it to a 347 and rev it hard you are way better off with an old 60s 302 mexican block if you can find one, ultrasound the bores so you know what youve got, they are way thicker and better than any of the latter model injected motors, just ask wazza he learnt the hard way. im not saying dont stroke youre existing block, plenty of fellas on here have but if you want to rev it hard and longevity its either a mexican or dart or similer. ive had that combo in another car for several years and its proven to be pretty stout. Cheers Tomcat

__________________

Nuts,,, Bolts,,, and 2 smoking barrels.

|

11-02-2012, 09:37 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

If you do put a stroker kit in the stock block throw a main bearing girdle on it at the same time. It's a fairly cheap piece but it will help hold you block together.

5.0L/302 Main Cap Girdles - SummitRacing.com

Tickford put them on the factory ford 347 stoker motors.

__________________

Mike Murphy

Melbourne Australia

|

11-02-2012, 03:37 PM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: Central Coast,

NSW

Cobra Make, Engine: DRB #145, Ford 5.0 HO

Posts: 227

|

|

Not Ranked

Not Ranked

Thanks for the advice TC and Mike.

If I go with a stroker kit, then the mains bearing girdle will be a must.

The Cosworth YD stoker engine I have in the commuter has this arrangement built in....so they also recommend it as well.

Now this is to dampen vibration, improve mains cap clamping force, thus reducing bearing drift and crankshaft float or drift....leading to longevity under higher rpm loads. Cheers ...I am sold if I go this way.

So, is their anything on the market for the big end side as well (noting I have only seen piston rods with two bolt holes for these engines), or is it unlikely that these caps and bearings will experience the same force loadings that would lead to spun big end bearings (outside of the use of premium bearings and caps compatible with the striker kit to be used)?

Also, I am assuming (cause I am not sure  ) that the 5.0 HO bottom end is identical or compatible with the 302 or ford boss SB listed in the Summit link.

There are some attractive options there. I need to pick the correct one that represents the best VFM.

I can not see the car sitting over 5000 rpm for extended periods outside of a track day, but better to build for the most extreme contingency, and only want to do this the once.

Cheers and thanks again

Last edited by ICETOO; 11-03-2012 at 04:11 PM..

|

11-03-2012, 12:12 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

Where is that pic of Wazza's split block.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

11-03-2012, 01:49 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Location: Gold Coast Queensland,

QLD

Cobra Make, Engine: Harrison#97 LS7 / T56

Posts: 1,682

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by boxhead

Where is that pic of Wazza's split block.

|

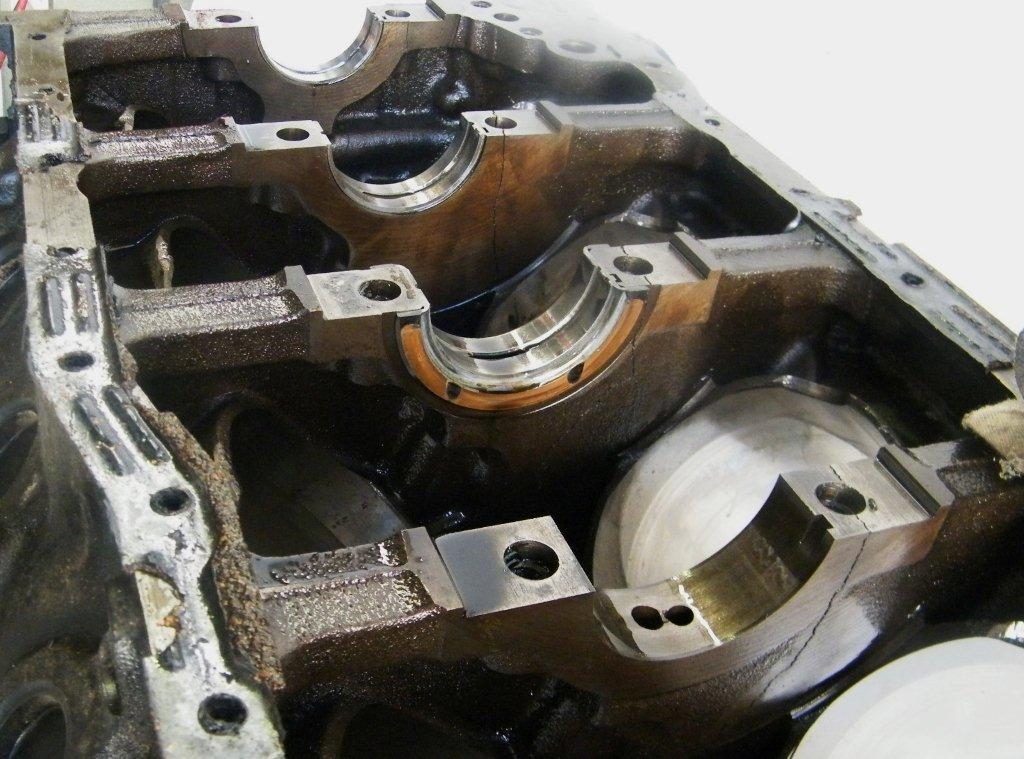

Here's the little darling !!!

LUCKY for me it had a GIRDLE fitted......

I would have been looking for all the bits for hours !!!!

The Dart Block that replaced it was the GO !!

And...The Four Bolt Mains look like they do a much better job than the pissy little Two Bolt caps...( Sitting on top in the photo )

Cheers,

Warren.

|

11-03-2012, 02:07 AM

|

|

CC Member

|

|

|

Join Date: Aug 2008

Location: airlie beach / mackay,

QLD

Cobra Make, Engine: Some kind of FORD thingy, with several pis tins, twin chain driven SUs feeding a Y block, apparently.

Posts: 501

|

|

Not Ranked

Not Ranked

the dart iron eagle block is even better, its 4 bolt caps all the way.

__________________

Nuts,,, Bolts,,, and 2 smoking barrels.

|

11-03-2012, 02:12 PM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: Central Coast,

NSW

Cobra Make, Engine: DRB #145, Ford 5.0 HO

Posts: 227

|

|

Not Ranked

Not Ranked

Thanks for the pics Wazza, great comparison with the mains caps.

Quote:

Originally Posted by tomcat racing

the dart iron eagle block is even better, its 4 bolt caps all the way.

|

TC, I am assuming you mean at the front and rear mains caps as well in this pic...

Now, I do not think the 5.0 HO has a 4 bolt mains...(any info here?), but if not the mains girdle should help...or is there a mob out there that can machine in extra bolt holes and webbing profile for a compatible 4 bolt mains cap....or are we looking at sourcing a block with this done from the get go..

Thanks Adz |

11-04-2012, 01:04 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I don't think there is enough material in the webbing in the stock block to be able to machine them for 4 bolt caps. In my opinion it would make the block weaker.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

11-05-2012, 12:05 AM

|

|

CC Member

|

|

|

Join Date: Jan 2011

Location: Bolinda,

vic

Cobra Make, Engine: Cobra-less

Posts: 91

|

|

Not Ranked

Not Ranked

347 stroker...

347 stroker...

Hi Ice,

I'm not sure what you want from your new drivetrain package, but since your drb kit seems to be the same as mine and I have recently had a 347 conversion completed, I thought you may be intereseted in my reasons behind the decision to go with this setup.

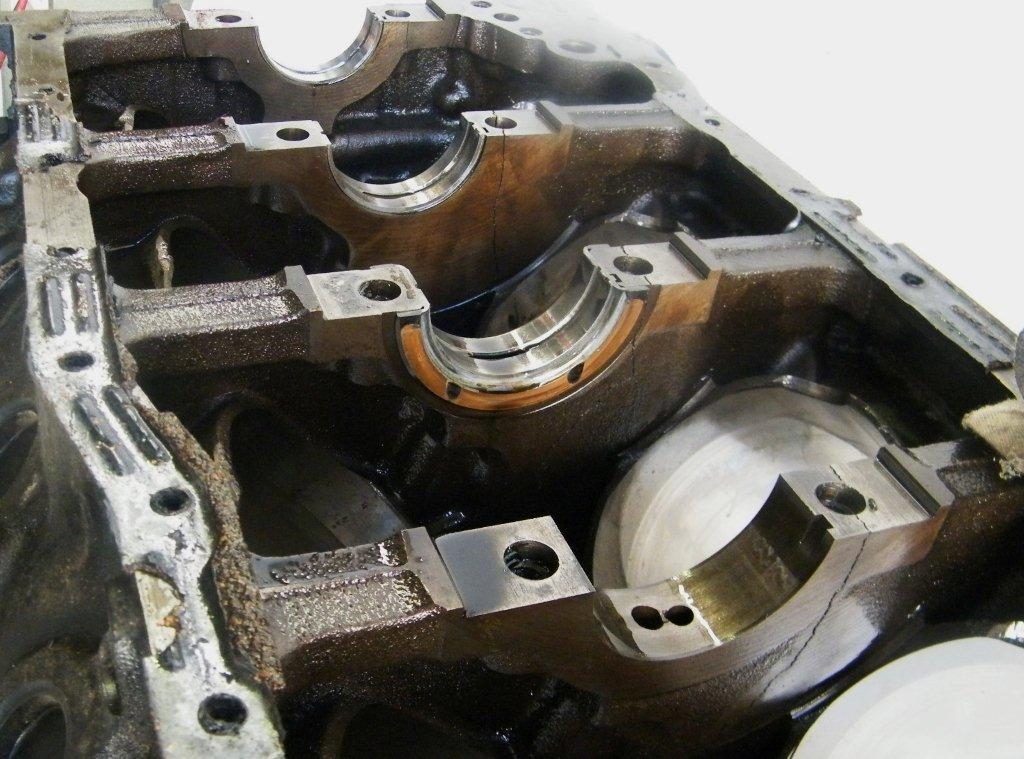

Here's a pic from my 347 bottom end.

The block came from a 91 stanga It's had 3 hard days on the dyno plus 2000klms on the road including a 1500klms round trip through the snowy mountains on the weekend without an issue. The rev limiter is set at 6500rpm and I don't think that it will spend too much time up in that range as peek tourqe is at 4700rpm.

My position is that although the thicker blocks (like the dart) give you some extra rigidity etc, they are not really essential when building a street donk that will do a little track time. The obvious weekness is in prolonged exposure to high rpm consistent with track racing. I decided that for me, it was more important to have a mildly lumpy street motor with quality internals than an ultimate screamer that can endure consistantly high rpm's. Another option if you would like to stroke you current block could be a 331 kit? Ofcourse you would have to have the block tested as mentioned by others.

The other significant factor in my decision was that I wanted to use the same block so that all of my documents remain current and there was no need to complicate any of my engineers documents.

My 2c

Last edited by Toecutter; 11-05-2012 at 12:24 AM..

|

11-05-2012, 01:08 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: Central Coast,

NSW

Cobra Make, Engine: DRB #145, Ford 5.0 HO

Posts: 227

|

|

Not Ranked

Not Ranked

Thanks again Mike and absolutely a good point.

Thanks also for the info on your set up Toe Cutter (thats so original Mad Max/Road warrior.... I like it), I am definately leaning for the 347 set up (is the 363 the same stoker kit but with over sized bores and pistons???), and definately want to use the same block that I have all ready for the reasons you highlighted.

This main girdle looks to be the way to go, noting the above and Mikes recommendations.

Thanks for the help with this guys, I am learning lots about this car now, and some good best practice recommendations are coming through loud and clear...so Cheers...Adz |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:53 PM.

|

|

7Likes

7Likes

) that the 5.0 HO bottom end is identical or compatible with the 302 or ford boss SB listed in the Summit link.

) that the 5.0 HO bottom end is identical or compatible with the 302 or ford boss SB listed in the Summit link.

Linear Mode

Linear Mode