Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

8Likes 8Likes

01-15-2013, 09:28 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Fuel system update

Fuel system update

For some reason I cant find my fuel tank build thread so I'll start a new one.

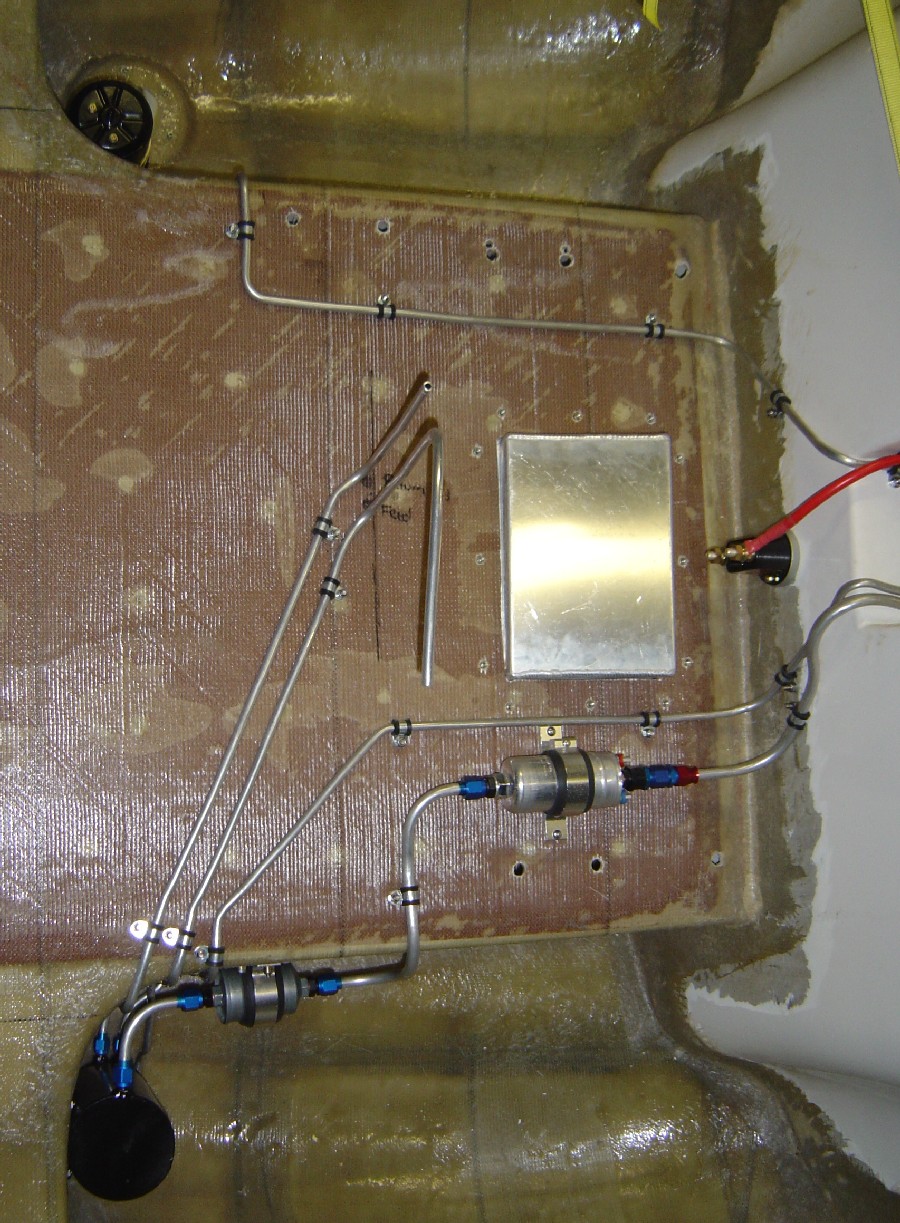

Previously I had a seperate swirl pot and 2 pumps (one in the tank and one external). I had a 1/2" line running up to the engine bay where the regulator was on the fire wall and then another 3/8" line going back to the tank. All the lines were attached to the inside of the tunnel. It was complicated with a lot of connections and clamps holding it in place. Also it turns out a lot of it was difficult to get to if I needed to fix anything.

It was a lot of fun doing all the plumbing and setting it up but in hind sight just too complicated. The new tank setup was designed to simplify everything and make it easy to work on. It also needed to work as well or better and be quieter than the old setup. Having the pump bolted to the underside of the boot floor was a bad idea. it ended up being louder than the engine when the quiet rego exhaust was on.

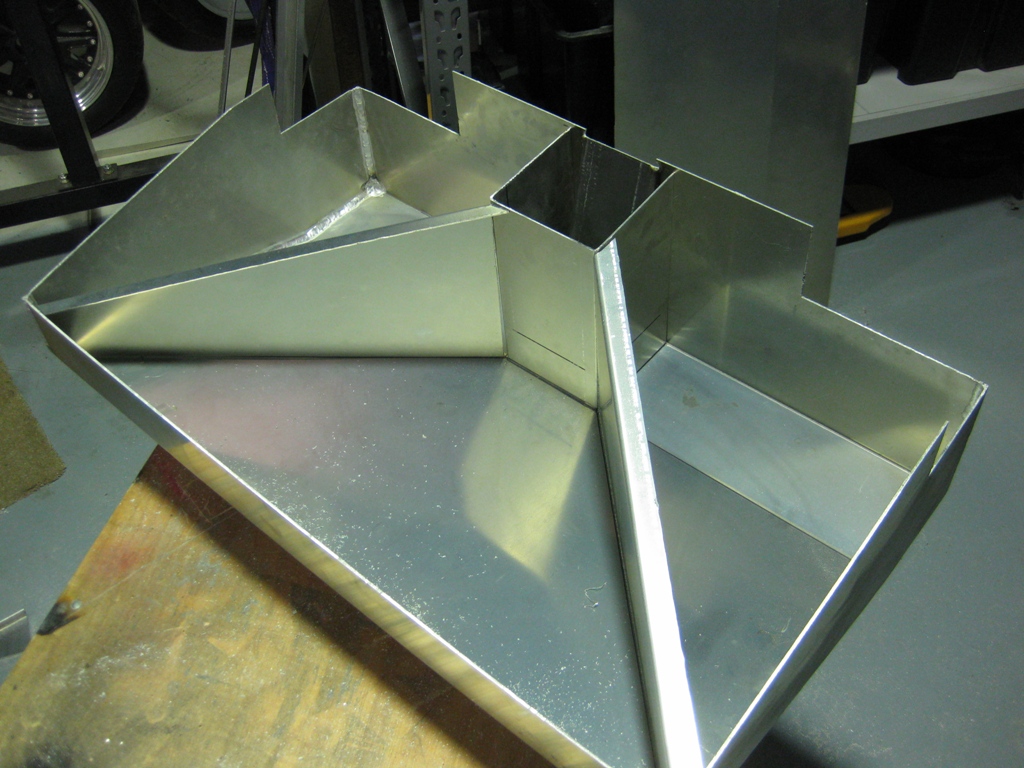

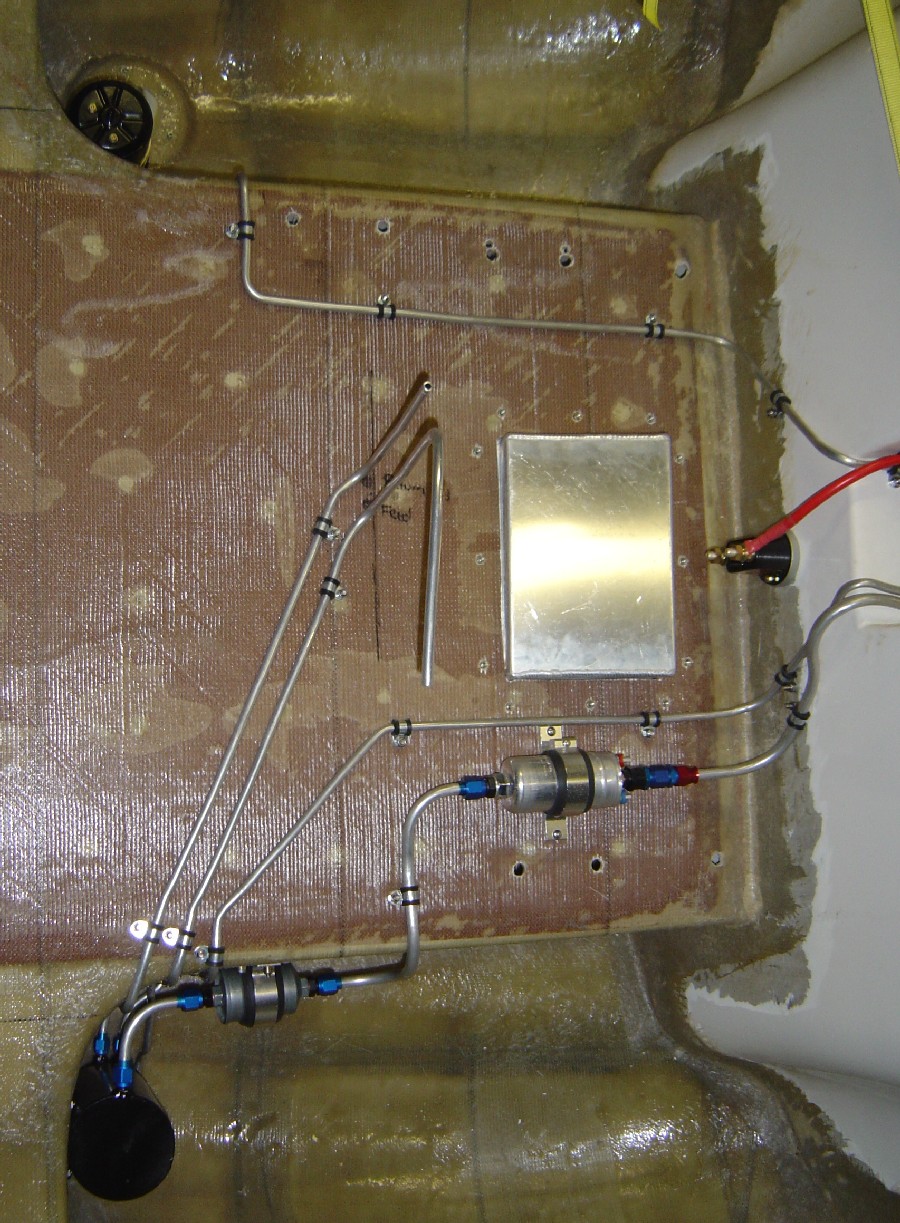

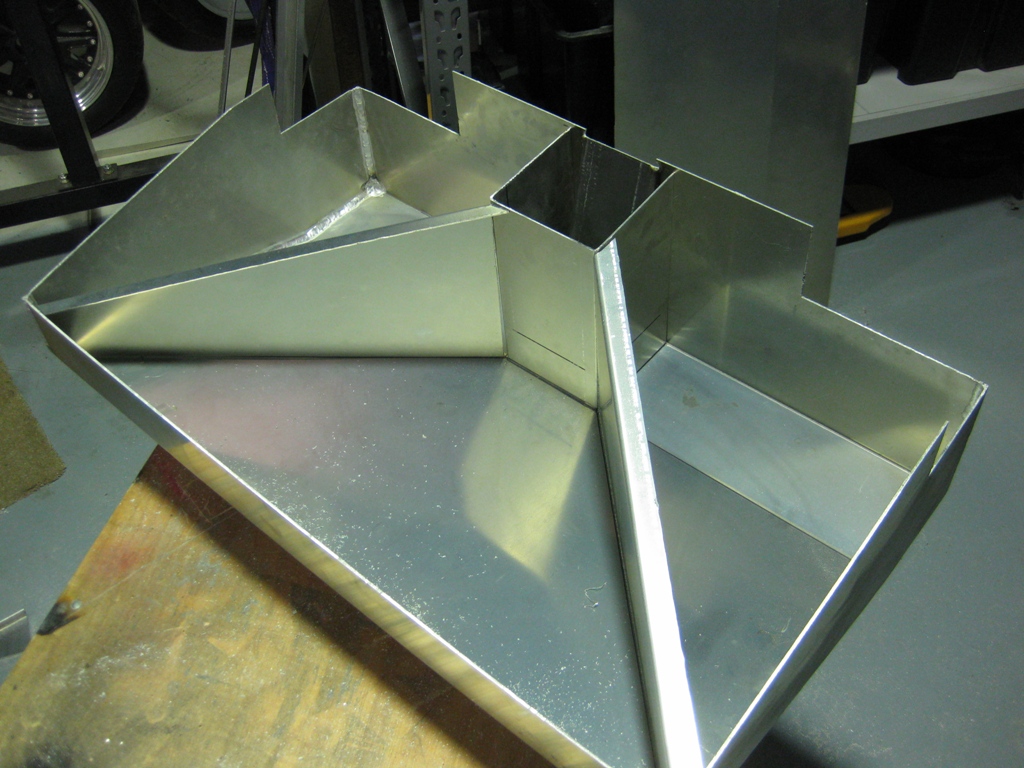

So the new tank has a much larger capacity, it's internally baffled and has the swirl pot and pump built into it. It also will hopefully look better than the old Commodore donor tank.

For those that missed the tank build thread...

Internal Baffles

An internal swirl pot with flap valves to keep it fed with fuel.

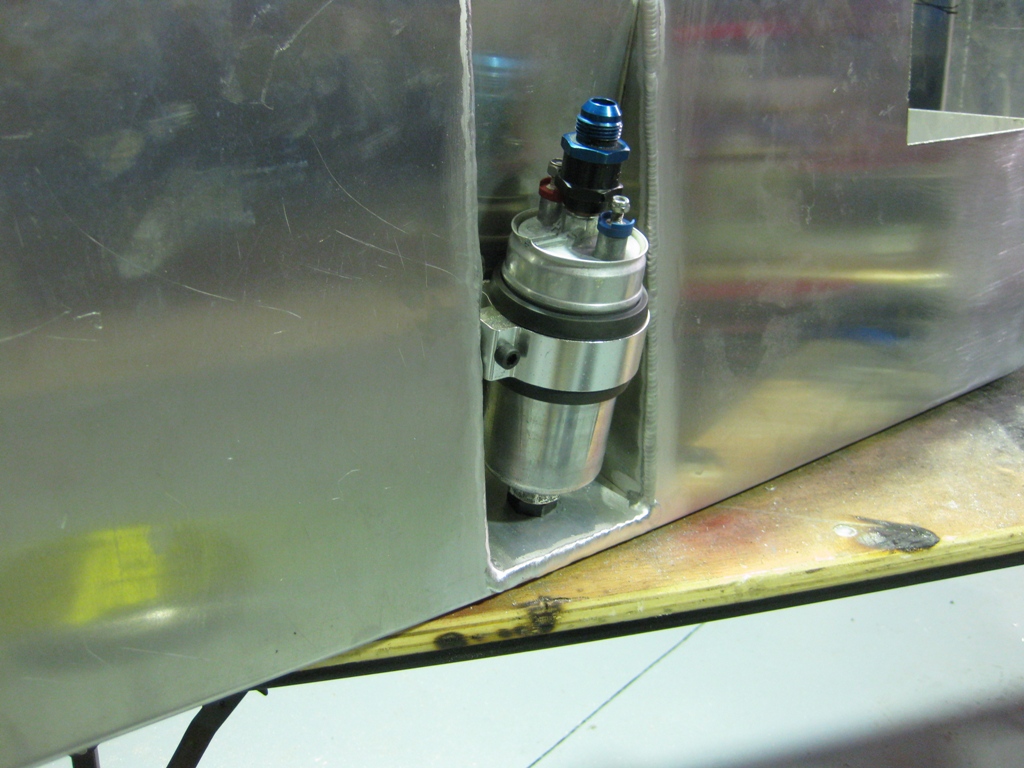

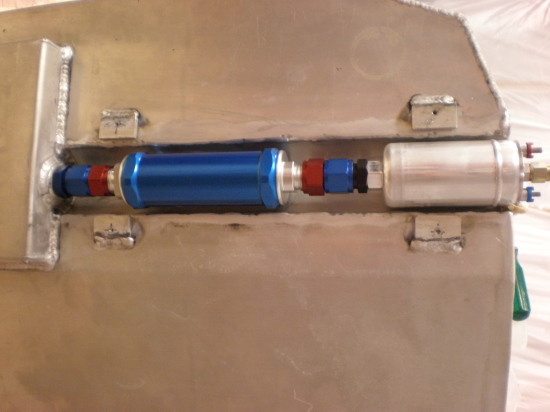

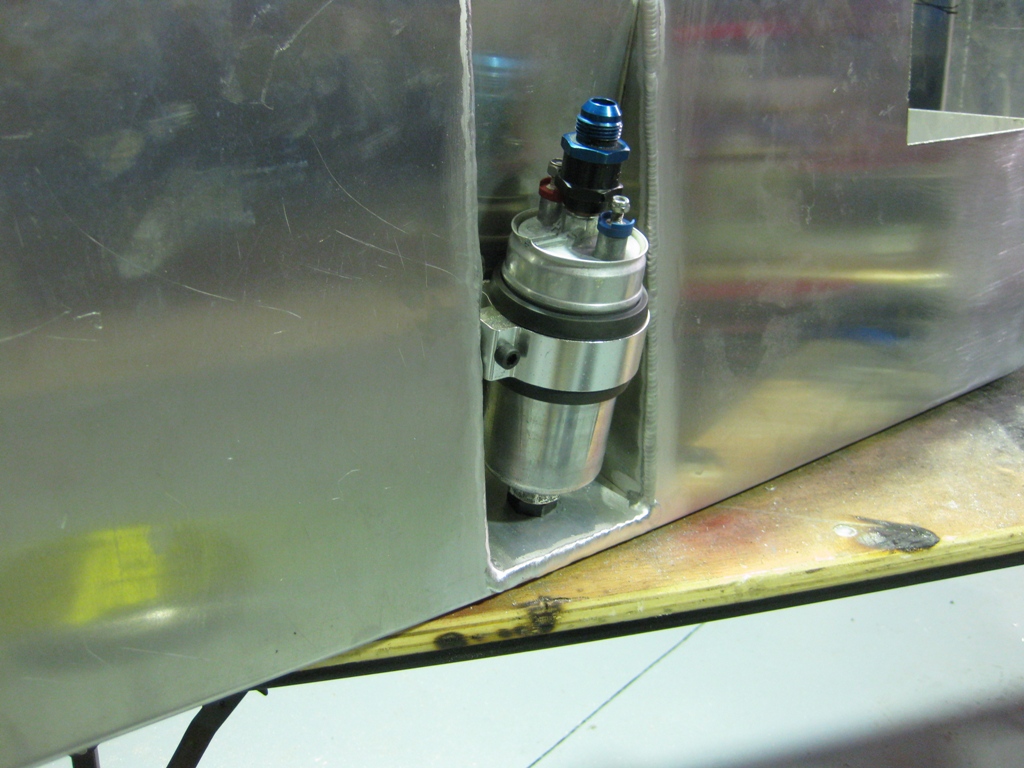

An External Bosh 044 set up to pick up fuel from the bottom of the swirl pot. I did it this way because I already had the pump and also for ease of servicing as you can just unscrew the pump to replace it without having to get inside the tank.

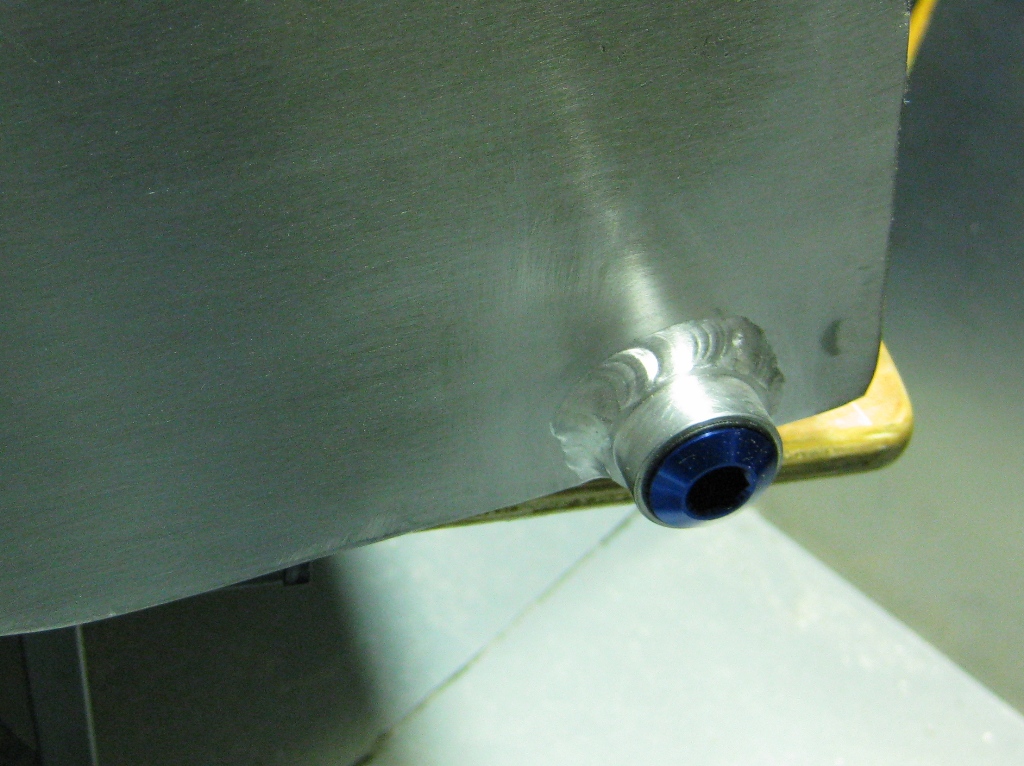

The tank is in place now and I'm plumbing in the fuel system to the motor. I've simplified things a lot here. I've mounted a bypass regulator on the tank next to the pump. Fuel from the pump goes direct to the reg and a port on the side bleeds excess pressure straight back to the tank. A single 1/2" line goes from here along the chassis to feed the motor. No return lines and not too many connections or clamps required. This is pretty much the same as the factory setup but supersized. Bigger pump and reg, bigger lines etc.

It had to be easy to work on and also safe from damage. I was always worried about some of my fuel lines heading up into the wheel arch where the swirl pot was.

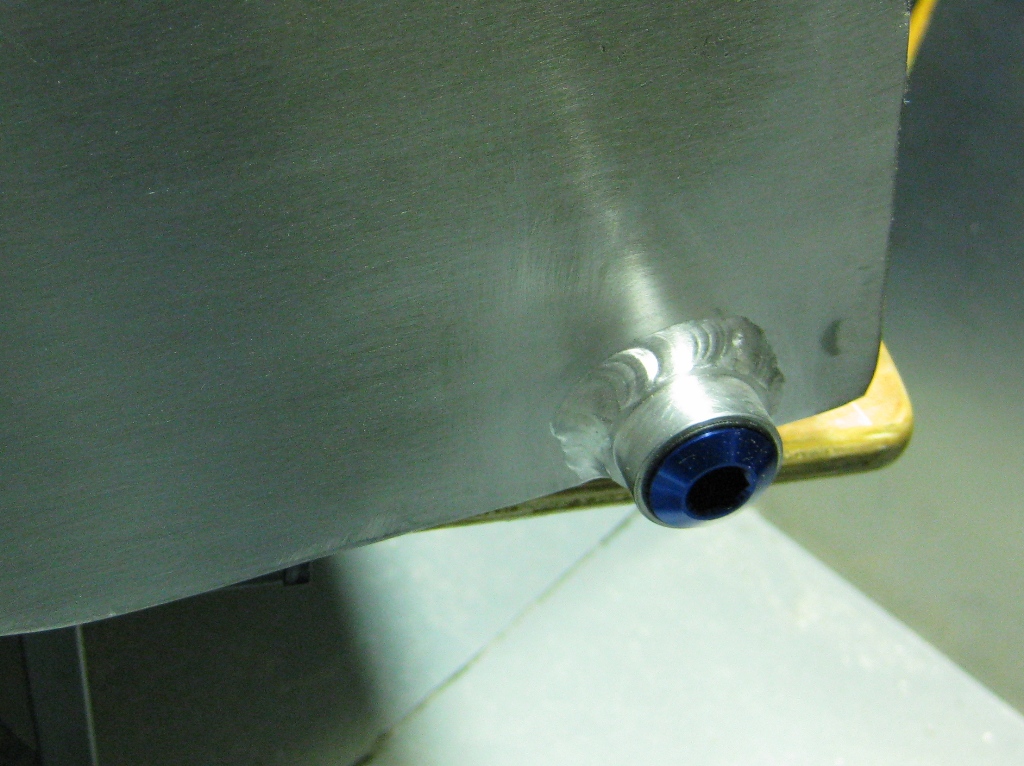

Here's the line where it goes from the reg on the tank down to a hard line on the chassis. Everythig out of harms way.

There's a tab welded to the chassis for a bulkhead fitting to support the line and make the connection between the flex line and the hard line on the chassis.

The hard line runs along the inside of the chassis rail where it terminates at the fuel filter.

The fuel filter was previously under the boot floor. Changing it meant spillling fuel all over the rear suspension arms and it was tricky to get at. The now location is dead easy to get to and no mess to change. It also acts as a transition between the hard line and the flex line to the motor which means a few less connections.

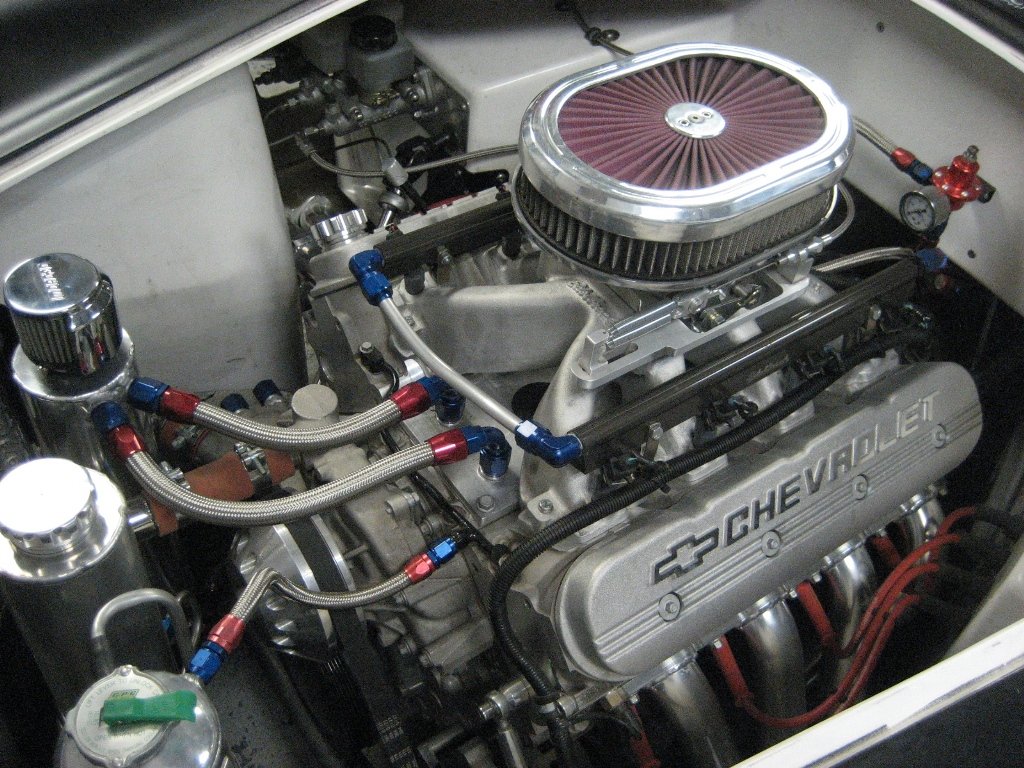

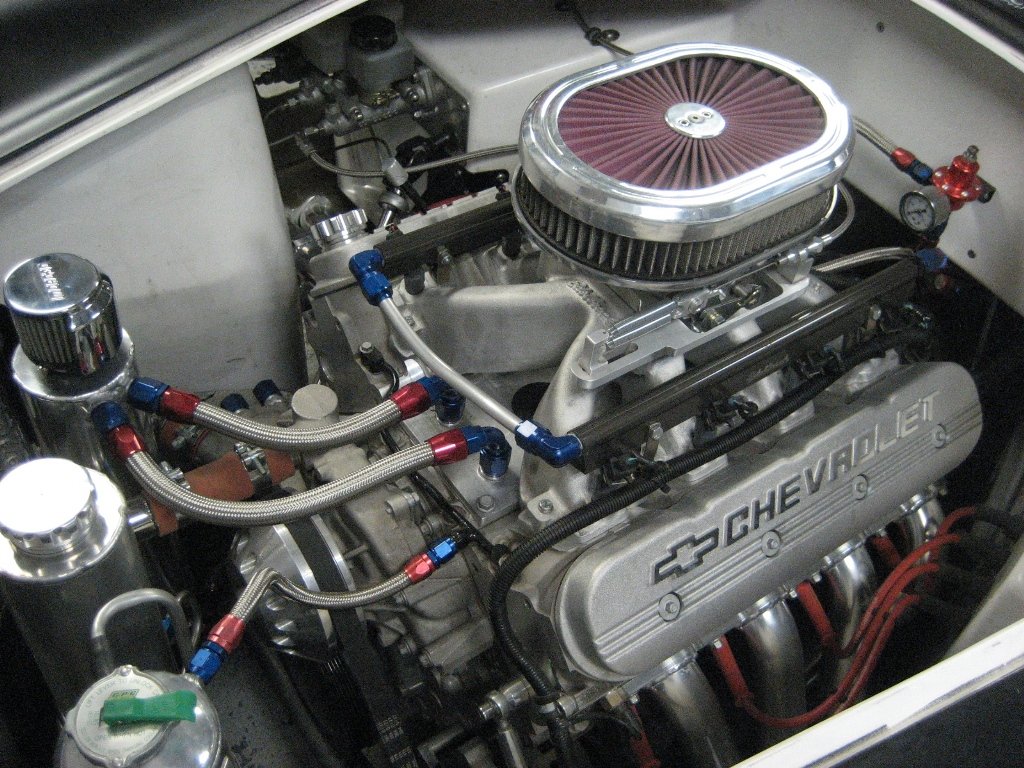

There's now a longer flex line connection from the hard line to the motor. This was something I worried about with the old setup. I only had about 8" of flex line between the hard line and the motor. I didn't realise how much the factory mounts let the motor rock and this short line chould have been a cause of fatigue and a break in the hard line.

The new flex lines are all teflon. With the variety of fuels these days I had some concern about the compatability of the old braided rubber lines. I also noticed that the fuel tended to permiate through them giving off a fuel smell. Teflon means I can run anything in the future, E85 etc with no worries.

The tank and all the lines can be removed in a matter of minutes. Everything is easy to access and work on. I think that one advantage of a hoist is you can stand underneath the and look at where everthing should go rather than imagining it.

The rails came in for some simplification too. One line comming in that is T'ed of to feed both rails. No more return lines etc

I've still got to machine up a couple of clamps to secure the line to the back of the cylinder head.

I still wanted the pressure guage so I plumbed that into the end of one of the rails and plugged the end of the other one.

Fuel pressure will be a bit more difficult to set because I've got to reach into the gap between the chassis and the tank but realistically once it's set I will probably never touch it again. The advantage is I'll be able to clean all the junk off the firewall for a neater look to the engine bay.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 01-15-2013 at 10:12 PM..

Reason: spelling

|

-

Advertising

01-15-2013, 11:00 PM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: Beerwah,

QLD

Cobra Make, Engine:

Posts: 218

|

|

Not Ranked

Not Ranked

I like it Mike..........There are times when keepimg things simple works very well.

Fewer connections the better, when it comes to fuel. Muzzza

|

01-15-2013, 11:08 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

I like it too. I have an external LP and HP pump and surge tank and its too complicated and loud. One of the other CR (round chassis) builders is using a "shortened" VE fuel/pump/surge tank/regulator/fuel level sender. I like that option - very simple - We havent seen it in operation to see how loud/quiet it is.

Well done Mike.

|

01-15-2013, 11:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2005

Location: Perth,

wa

Cobra Make, Engine: Pace Alumina 427 #69

Posts: 1,615

|

|

Not Ranked

Not Ranked

Nice work Mike.

__________________

RF12 414 Windsor 8 stack ,6spd, Avons

|

01-15-2013, 11:21 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I'm curious as to how loud this thing is going to be. I'm hoping the fuel in the tank will provide some noise and vibration damping. When the pump was mounted to the boot floor it made the whole boot cavity resonate. I reckon it won't be hard to improve on that.

The late model commodore pump assembly is hard to go past these days for simplicity/cost etc

Cheers.

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 01:40 AM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Cobra Make, Engine: 347 Stroker Morrison Injection. Registered.

Posts: 1,440

|

|

Not Ranked

Not Ranked

Mike, I don't know a lot about cars but if your feeding both fuel rails from the back of the motor and have a pressure gauge on one of the rails at the front how can you plug up the other rail at the front?

Regards.

__________________

Mando

|

01-16-2013, 02:59 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Mando

Mike, I don't know a lot about cars but if your feeding both fuel rails from the back of the motor and have a pressure gauge on one of the rails at the front how can you plug up the other rail at the front?

Regards. |

There is a T piece where it connects to the back of one of the rails and a line from there feeds the other rail much like the stock setup. With this setup there is no return line to the tank but I want the supply distributed evenly to both rails so I put the T and the cross over at the back close to where the fuel line connects. Pressure and flow in both rails should be the same.

With the old setup I had the cross over on the front of the rails. Fuel was supplied to the back of one rail, ran down that rail and jumped across to the other rail. It would then run back down that rail where it would hit the regulator and return to the tank.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 07:08 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Here's the regulator setup on the tank

For some reason the pic keeps flipping on it side

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 01-16-2013 at 07:16 AM..

|

01-16-2013, 09:30 AM

|

|

CC Member

|

|

|

Join Date: Mar 2010

Location: Gold Coast,

QLD

Cobra Make, Engine: Arntz, TKO600, 460

Posts: 818

|

|

Not Ranked

Not Ranked

Freaking awesome. I was wondering how the reg set up at the tank was until I saw the last pic. Great ideas and very neat and I like the short return line and simplification of it all.

Threads like this are so good for sharing information and innovation and a pic tells 1000 words.

Just awesome, and now I see the deficiencies in my set up..... add to the 'to do' list.

|

01-16-2013, 02:41 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Thanks Leroy. One thing to remember though, I might not be right in my thinking. I've been wrong with my stuff in the past. I think that's why I like to put the ideas behind what I've done with each step in the posts. I'm definitely open for comment and criticism.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 05:17 PM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Cheltenham,

Vic

Cobra Make, Engine: Classic Revival CR3516, LS3, Aussie Mike'd T-56, 3.70 LSD, AP brakes, Penske shocks

Posts: 1,616

|

|

Not Ranked

Not Ranked

What sort of reg is it Mike?

__________________

BUILD-BLOG: http://cobrablog.holnet.net

Ben in AU

|

01-16-2013, 05:57 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Modena

What sort of reg is it Mike?

|

It's an EFI Bypass regulator made by ProFlow which is VPW's own brand.

PFE Fittings

EFI Bypass Regulator

I originally wanted a new model Aeromotive one but they were out of stock. The Proflow one was a bit more expensive but seems well made.

This is the Aeromotive one I wanted: Compact EFI Bypass Regulator

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 06:42 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Darwin,

NT

Cobra Make, Engine: Classic Revival Kobra,LS7 427

Posts: 380

|

|

Not Ranked

Not Ranked

Hi Mike

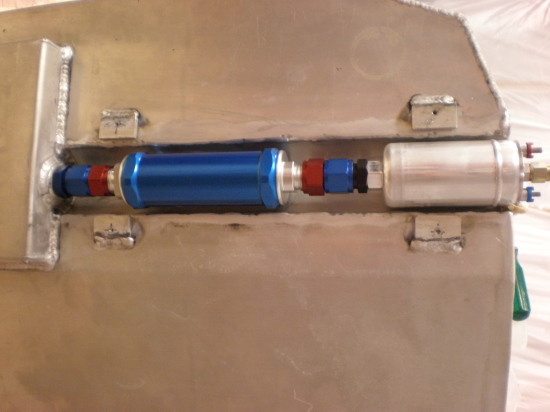

I also only have a single hard line from the tank to the engine, I have my swirl pot in the tank and a reg right next to the 044, it is still loud, but can only just hear it at idle

<img src="http://www.clubcobra.com/photopost/data/500/200903040013.jpg" />

http://www.clubcobra.com/photopost/d...0903040015.jpg

http://www.clubcobra.com/photopost/d...0903040015.jpg |

01-16-2013, 06:48 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Darwin,

NT

Cobra Make, Engine: Classic Revival Kobra,LS7 427

Posts: 380

|

|

Not Ranked

Not Ranked

|

01-16-2013, 07:42 PM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

Mike

It's a shame you didn't internally mount the fuel pump as I too can attest to the noisiness of an externally mounted 044 pump.

I had Marty modify the stock G-Force tank to enable me to fit a standard BA or BF fuel catch can and level sensor and this was very much quieter and even easier to fit into the car, particularly when I used the stock plugs to connect up to my loom.

As to accessing the pump I will simply be unscrewing a lid in the boot floor to access the top of fuel tank and the bolt mount points for the in-built swirl pot.

Presume it is too late or too messy for you to revise the pump set up but most modern cars now run in tank pumps as you'd know and with great success of course.

Enjoy your tinkering all the same.

Cheers

Steve

__________________

slowy

|

01-16-2013, 08:11 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Hi Slowy. Again it was one of those things that are fun to do. It probably would have been easier to buy a new intank pump but where's the challenge in that

One thing I do reccomend people do when building a tank is put in a drain. Having tried to un mount a half full commodore tank that was in there I figured a drain plug was a must have in the new tank. An empty tank is dead easy to lift into place.

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 08:58 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by alffie

Hi Mike

I also only have a single hard line from the tank to the engine, I have my swirl pot in the tank and a reg right next to the 044, it is still loud, but can only just hear it at idle

|

Nice work Alfie. I remember looking at the pics of your tank when I started on mine.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-16-2013, 09:03 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Aussie Mike

One thing I do reccomend people do when building a tank is put in a drain. Having tried to un mount a half full commodore tank that was in there I figured a drain plug was a must have in the new tank. An empty tank is dead easy to lift into place.

|

I agree Mike, When I had to revise my pump setup I had to wait until I had driven the car til the tank was almost empty and then jack it up on one side so fuel didnt leak everywhere when I unbolted the inlet. I hate working with things when there is fuel around - always have an extiguisher on the ready, although I'd say with Petrol is more the risk of explosion than fire that worries me.

Cheers Gregg |

01-17-2013, 03:28 PM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

Agree about the drain plug Mike, just that I forgot to ask Martin to do that too when I had him playing with the tank.

If necessary though I could always remove the sender unit but I'd err towards a syphon hose first given there is no anti tamper arrangement in the filler cap and fill hose.

__________________

slowy

|

01-17-2013, 04:41 PM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

I have an Aeromotive pump, filter and swirl pot in the boot of mine.

It was VERY loud to begin with but I then fitted rubber mounts and it is fine.

Without the hardtop on you vw hardly hear it.

That being said though, with a car with a lumpy cam and sidepipes it is hard to hear anything.

Well done Mike, another well executed job by Mikey's race fabrication.

__________________

Powered by Cu

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:54 AM.

|

|

8Likes

8Likes

Linear Mode

Linear Mode