Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

02-23-2013, 02:37 AM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

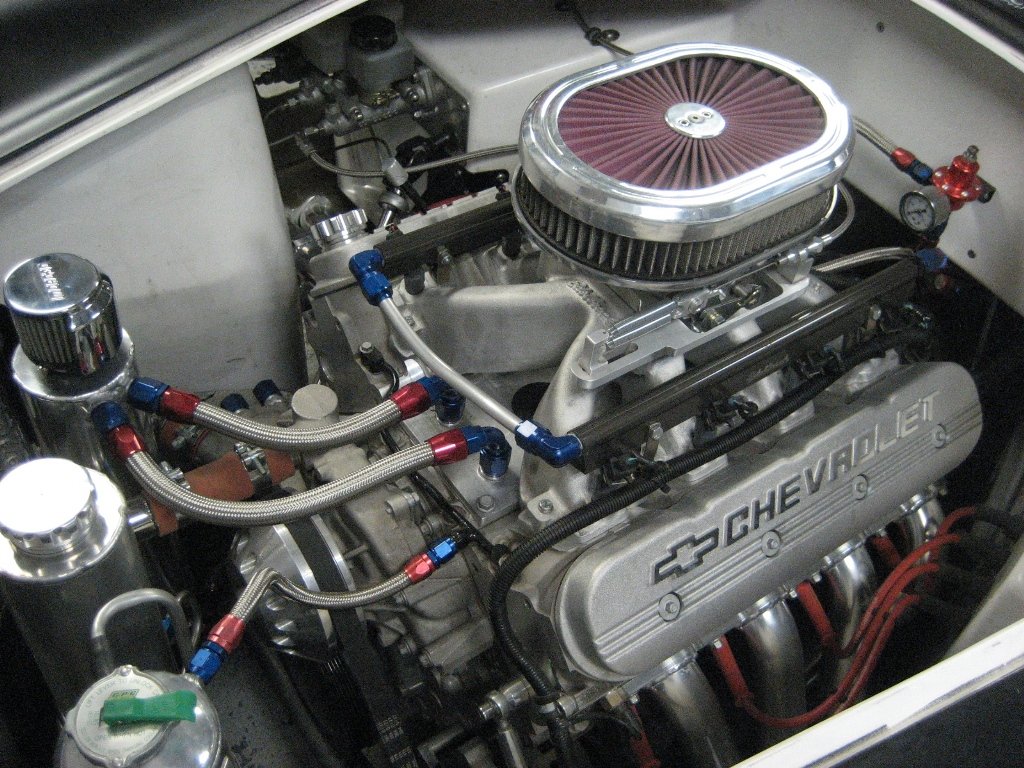

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

where is anoil preeure switch

where is anoil preeure switch

sorry to be a bit stupid ,, but i cannot find where to fit my oil pressure switch to as i know the water temp switch is at the back of the valley

so what is the sensor on the left hand head front

the motor is a ls1

helf

__________________

not all your babies are your children

|

-

Advertising

02-23-2013, 02:53 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Factory oil pressure is in the back of the valley. Water temp is in the passengers side head near the front (above the Alternator).

If you want to put in an aftermarket gauge then you can tap off the plate above the oil filter.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-23-2013, 03:12 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by renovationinnov

sorry to be a bit stupid ,, but i cannot find where to fit my oil pressure switch to as i know the water temp switch is at the back of the valley

so what is the sensor on the left hand head front

the motor is a ls1

helf    |

As Mike has said.

Both are sensors, oil pressure sensor at back of valley, water temp sensor at front outside of LH cylinder head.

There is a corresponding bung for water temp on the outside rear of the RH head.

__________________

Gary

Gold Certified Holden Technician

|

02-23-2013, 03:17 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

What are you hooking up to it? Ecu?

It won't work with normal oil gauges I don't think. I tapped a 1/8npt fitting into the cover above the oil filter for oil pressure. |

02-23-2013, 03:42 AM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

im tring to do my oil & water senders so i can hook up my gauges as i just had the harness stripped down & all i have is a wire marked water temp & oil pressurebut they left the plug for the original temp switch

plus some extras for themos

ROB

__________________

not all your babies are your children

|

02-23-2013, 04:24 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Cheltenham,

Vic

Cobra Make, Engine: Classic Revival CR3516, LS3, Aussie Mike'd T-56, 3.70 LSD, AP brakes, Penske shocks

Posts: 1,616

|

|

Not Ranked

Not Ranked

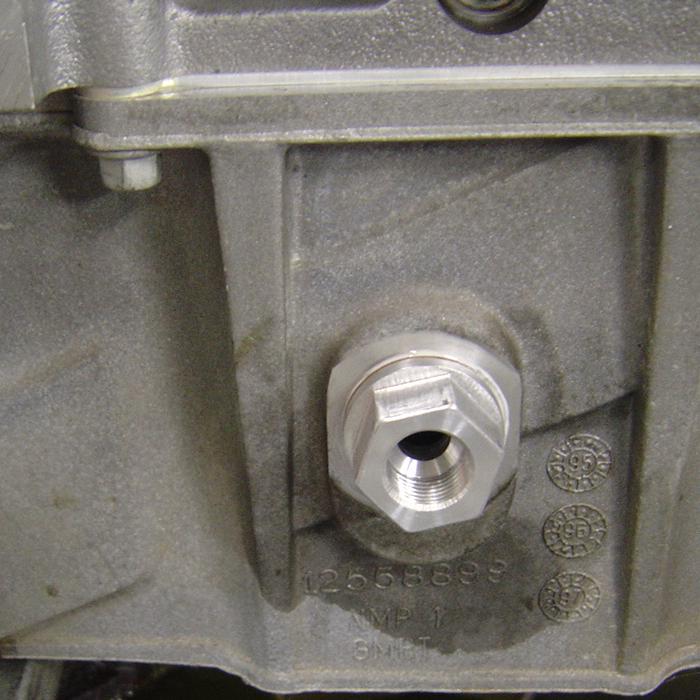

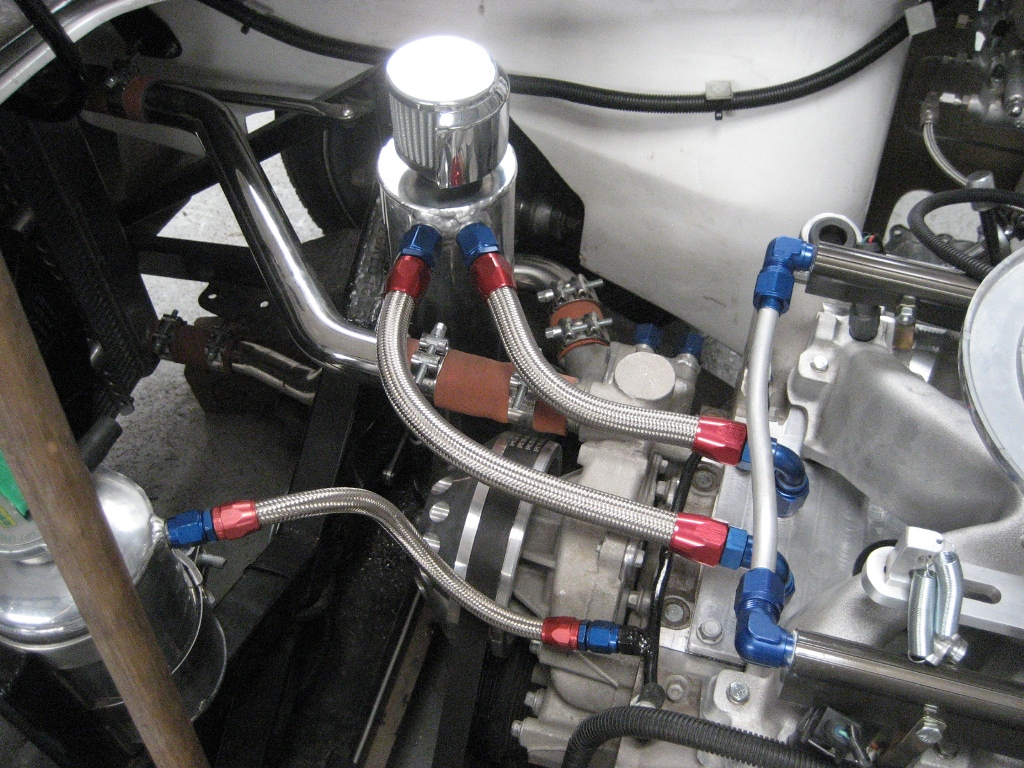

depending on your gauge you may not be able to use the factory oil sender. For an LS1 most people tap this plate to 1/8' NPT above the oil filter, as the plate is not used for anything on the Aussie LS1's;

__________________

BUILD-BLOG: http://cobrablog.holnet.net

Ben in AU

|

02-23-2013, 09:53 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

The water temp sender should be at the front of the engine. The coolant flows through the block, and cools the cylinders. Then it goes up into the heads, and foreword to the thermostat, and then (of course) to the radiator. If you put the gauge sender in the back of the block, it will only read the coolant temp as it leaves the block, not as it leaves the head. It won't provide you with usable information.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

02-23-2013, 02:06 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

You need sender units compatible with your gauges, you won't get correct readings otherwise.

__________________

Gary

Gold Certified Holden Technician

|

02-23-2013, 03:08 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

On the same theme as Modena mentioned above I used an after market block off plate from Improved Racing. This gives you 3 x 1/8" NPT ports for Oil Pressure, Oil Temp and for Oil Supply for Turbo.

$100 bucks landed in AUS.

|

02-23-2013, 10:20 PM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

thanks all

as modena has done i tapped a 1/8 npt in top of the oil filter & added a tee piece so as the oil temp & pressure could work

thank all

ROB

__________________

not all your babies are your children

|

02-24-2013, 08:35 PM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

ok ive got the oil pressure up & running , but now i find that water temperture is hard to access at the right hand back of the head & i need the left hand sender to run the ecu control so where do i look next or is there a place [ eg like remove out lets for heater pipes & tap a bung with a 1/8 npt thread in to run the temp gauge

rob

__________________

not all your babies are your children

|

02-24-2013, 08:59 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by renovationinnov

thanks all

as modena has done i tapped a 1/8 npt in top of the oil filter & added a tee piece so as the oil temp & pressure could work

thank all

ROB

|

Not a particularly good spot for the oil temp sender. That's a dead space, with no oil flowing through it. It will eventually warm up through conduction. But it will be slow to respond, and probably never read the max temp of the oil.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

02-25-2013, 01:45 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I put the oil temp sender in the sump. On US crate motors there is a threaded boss on the side of the sump where the sump heater screws in. I just machined up an adaptor to plug the sensor in there.

If you are game to unbolt the sump there is enough meat in the side of it to drill and tap a hole for a sender. Then you will be measuring the temp of the oil directly in the sump. It's dead easy to unbolt the sump. It uses an O ring gasket that is reusable.

As for the water temp sender, I've seen some people drill and tap for a sender into the top of the water pump. Some models of pump have a flat boss in the casting there ready for a different style of water neck. It makes a good spot for the sender. LS1 thermostat restrict water into the motor rather than out of and the thermostat is in the suction pipe of the pump.

I used the blocked off hole in the drivers side head for mine but drilled it out larger for a mechanincal sender (a whole 'nuther story). Stock it has a 12mm thread and it'd be easy to make up a 12mm to 1/8NPT adapter and that would require no drilling.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 02-25-2013 at 01:48 AM..

Reason: spelling

|

02-25-2013, 03:36 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

Mike, isn't that the oil level sensor location? Drivers side of the sump?

Any one install a steam pipe between the water pump and heads?

|

02-25-2013, 04:09 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2007

Location: North Gold Coast,

Qld

Cobra Make, Engine:

Posts: 820

|

|

Not Ranked

Not Ranked

easiest way to do it is

remove ls1 oil pressure sensor

break off plastic part and dig out electrics

u will have an alloy piece left

drill and tap the centre to suit your new oil pressure sender

with water u can make or buy adaters to screw into drivers side head right at back

u just have to remome allen key bolt

i have run out of the adpaters but i can get more easily when i order some other stuff

from my guy who makes em

or u can drill and tap a hole in flat sevtion on water pump

if u fit a sensor in a pipe between radiator and engine make sure u weld a small nut so u can run n earth wire from pipe/sensor to ground or your sender will not be earthed and gauge wont work

|

02-25-2013, 04:21 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Sorry, yes you are right. It's an oil level sensor, I just looked it up. I'd assumed it was a sump heater connection for cold climates since the Aussie motors didn't seem to have it. My Holden sourced loom didn't have a connection for it either.

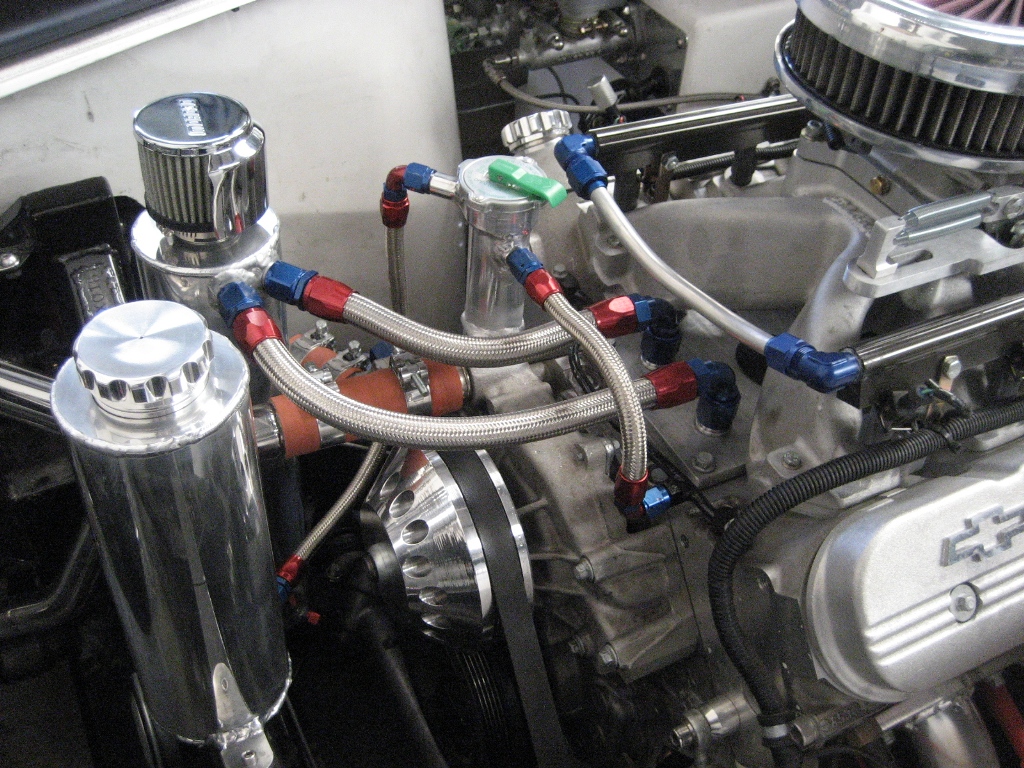

I've connected the steam pipe to the water pump but I made a filler neck and pressure cap fitting and welded it to the pump. That let me delete the header tank. Previously I had the steam pipe connected to the header tank. I reckon it needs to go to or near the highest point in the system to purge any trapped air out of the system.

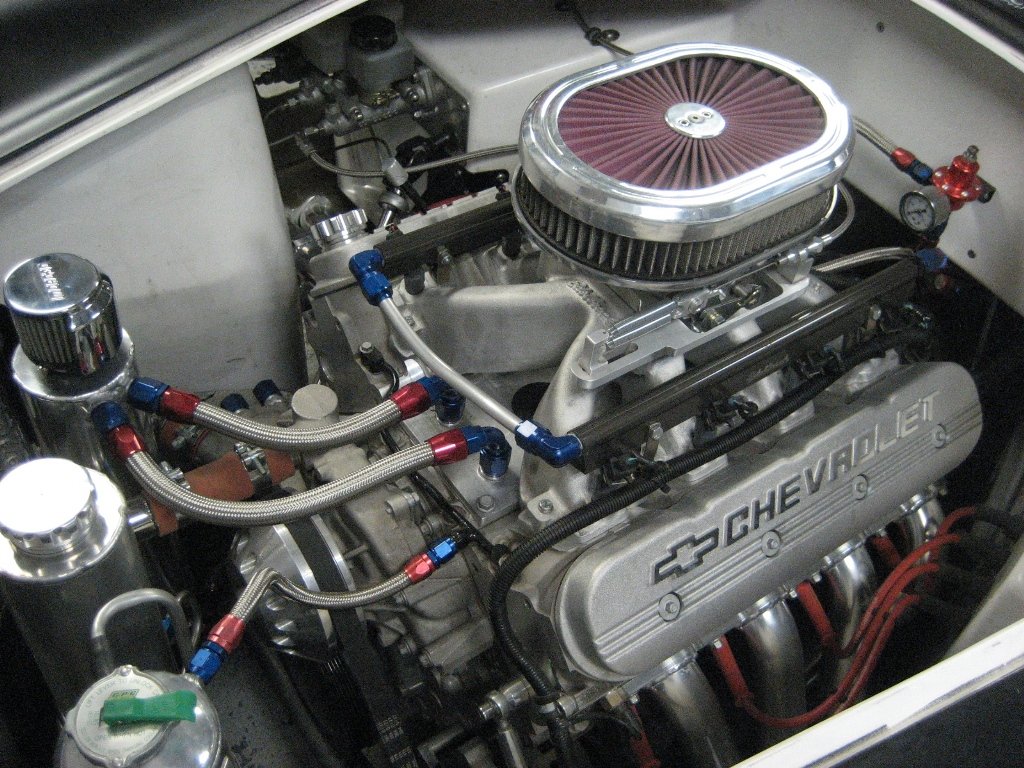

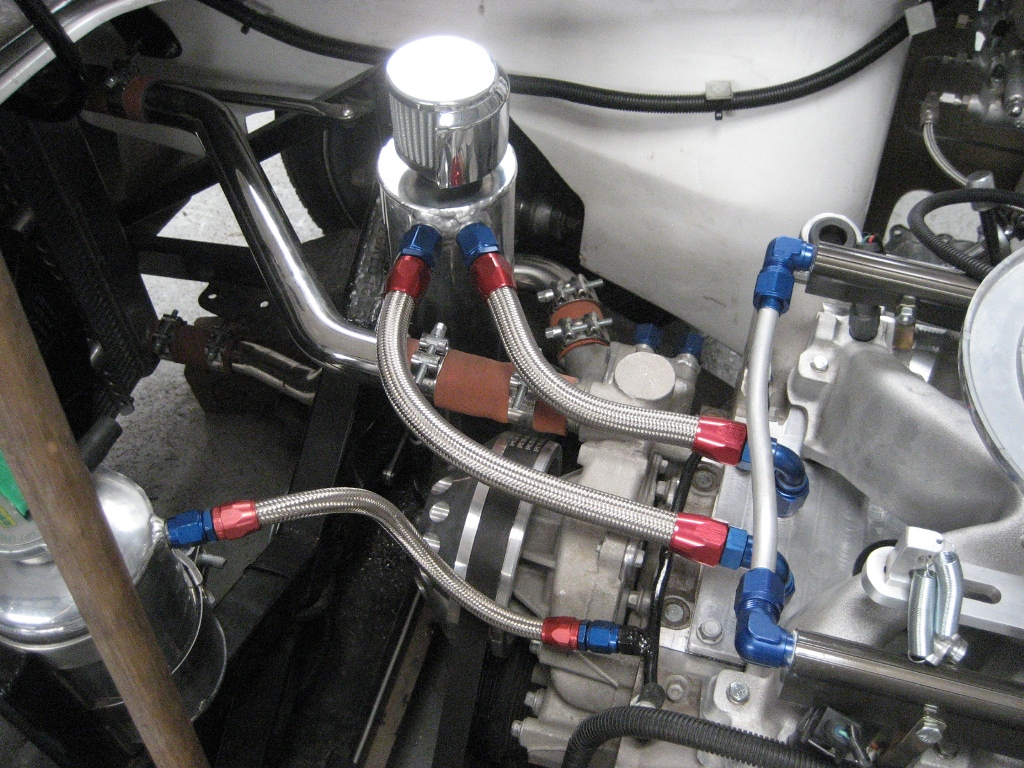

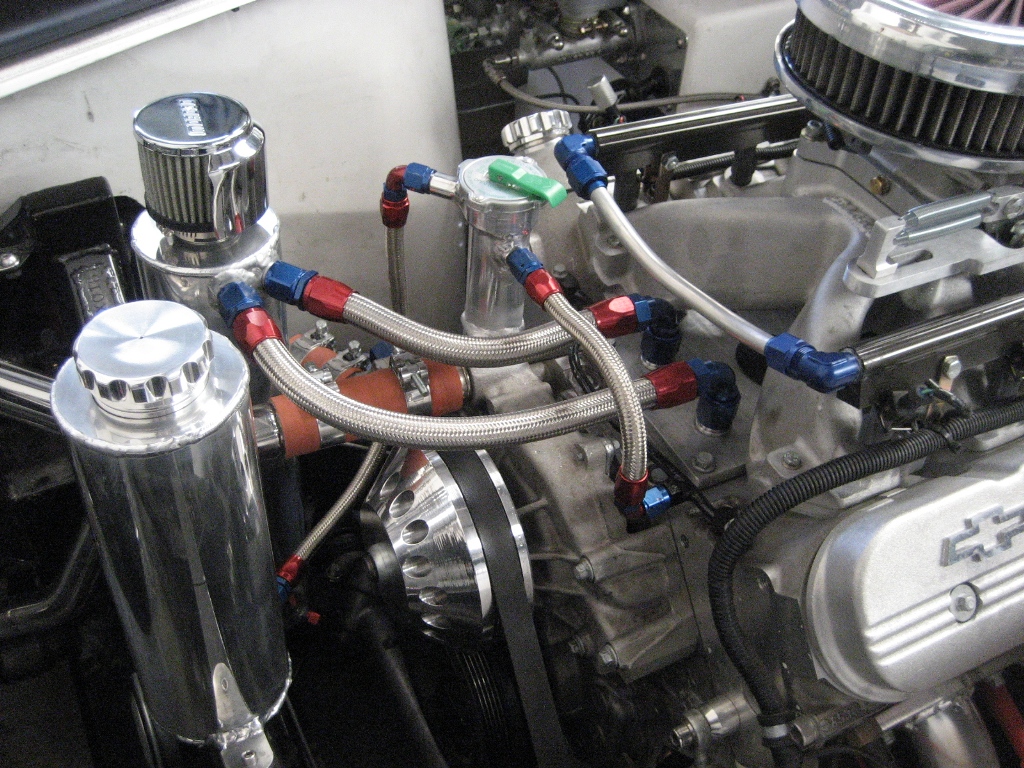

How it's set up now.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-25-2013, 08:20 PM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

thanks guys

side show could you get me one of the rihgt hand head adaptors ...please & if i did the rear block manifold modifaction can i run the oil temp from it instead

thanks again

ROB

__________________

not all your babies are your children

|

02-26-2013, 03:44 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

looks good Mike,

How did you have the header bottle connected before welding it to the pump? I was planning on using one of those inline radiator cap fittings (straight pipe with a neck on it) up close to the water pump and then just using a recovery tank from that rather than having a full header tank.

Did you drill out the steam pipe ports at the rear of the heads also? I cant see a connector in the photo. Not sure how important this is until major mods are made to the engine.

|

02-26-2013, 06:24 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Early ls1 motors had a steam pipe cross over front and rear of the motor. These were then connected together with a pipe running under the manifold. With the introduction of the LS6 the rear cross over and tube under the manifold was deleted. I think this was mainly because the plenum area of the LS6 manifold is deeper and it sits down closer to the valley plate so no room for the pipe.

I've seen where people have drilled out the steam pipe holes and used AN fittings. I'm tempted to do this myself. I have just silver soldered some Bundy tube into the original bosses and soldered on an AN-6 fitting in the middle. I made up a matching cross over at the rear that eliminated the front to rear connection.

The header tank had an AN-10 on the bottom that ran to a fitting about half way up the radiator tank. 2x AN-6 fittings at the top were for purge. One ran to the steam pipe on the motor and the other went to a -6 fitting on the top of the radiator tank. The system filled really easily with air being purged from the motor and the radiator at the same time.

The tank is on Gav's car now.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 02-27-2013 at 02:53 AM..

Reason: spelling

|

02-28-2013, 03:29 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Sydney,

NSW

Cobra Make, Engine: RCM, Jag front and rear, LS3

Posts: 1,640

|

|

Not Ranked

Not Ranked

Mike, where does the hose go that is coming out of the top of the welded on neck?

I am trying to work out the best option for my set up, but the steam pipe is confusing me.

My radiator filler is about 20mm lower than the upper hose on the water pump, but the steam pipe is then higher again.

Original plan was to install one of these inline fillers Moroso Radiator Hose Fillers 63745 - SummitRacing.com near the upper hose on water pump to allow it to fill without air getting trapped (or would it still be trapped in heads?). I was then going to just run the overflow to a recovery tank. Only problem is the steam pipe would be higher. Do you think it would work to just tap the steam pipe into the inline filler? Not sure if the air/steam would push through into the system or get stuck at the top of the pipe. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:21 PM.

|

|

Linear Mode

Linear Mode