Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

386Likes 386Likes

05-20-2015, 06:17 PM

|

|

CC Member

|

|

|

Join Date: Jun 2001

Location: munno para west,

sa

Cobra Make, Engine: absolute pace chassis #50 L98 & 6 speed auto

Posts: 1,141

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by guye

Mike, I'd be interested in borrowing your nifty alignment tool for the quick jack holes. I elected not to get my holes drilled at the factory, because I can get the car registered easily without bumpers. But not quick jacks. And I'm not 100% sure what I'll put on yet. But the holes, especially at the front as you mentioned, will be a bit tricky at the surface is uneven.

|

i had the holes drilled in mine as i remember doing them in my last cobra and almost ended up half a hole out even after measuring a few times before drilling them thru so i elected to have them done up at the factory . anyone with a pace close to you that has the holes cut you can make a cardboard template from ?

cheers dean

__________________

a cobra is a passion anything else is just a car

i dont care what the question is .. The answer is more power!!!

|

-

Advertising

05-21-2015, 04:51 AM

|

|

CC Member

|

|

|

Join Date: Mar 2010

Location: Gold Coast,

QLD

Cobra Make, Engine: Arntz, TKO600, 460

Posts: 818

|

|

Not Ranked

Not Ranked

Great update and über cool fabrication work as usual.

That belt alignment tool is just awesome.

For what's its worth, my old car has a squeaking belt and I knew it was an allingnment issue. I remover the belt and used builders string line Around the belt path and sighted this by eye. The idler pulley was out 1.5mm. So I changed the spacer behind the pulley and it all lined up, squeak gone.

|

05-21-2015, 04:59 AM

|

|

CC Member

|

|

|

Join Date: Jan 2002

Location: Melbourne, Australia,

VIC

Cobra Make, Engine: AP Pace427 (AP4033) GM L77 6.0L TR6060

Posts: 838

|

|

Not Ranked

Not Ranked

Hardly too stupid! I like the idea!

__________________

Guy

Cobra Progress guye-cobra.blogspot.com

|

05-21-2015, 09:07 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Cobra Make, Engine: Manufactured by Me, 408 Windsor, TKO600, 3.3 Jag rear

Posts: 40

|

|

Not Ranked

Not Ranked

Mike and Spookypt,

I have the same issue with my DSC ie. 1 rib cut off the 6 rib belt. Now I have run the car at a few Nationals and Shelbyfests and have not had an issue - YET. I contacted the aircon company who imports the pumps and they advised that the pump does not come with a 6 rib pulley, only 5 and I cannot see how the pulley can be removed. If you come up with a way of removing it and fabricating a 6 rib pulley or finding one that suits, I am in

__________________

Serpnt

Melbourne

|

05-24-2015, 04:00 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Cobra Make, Engine:

Posts: 2,752

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Serpnt

Mike and Spookypt,

I have the same issue with my DSC ie. 1 rib cut off the 6 rib belt. Now I have run the car at a few Nationals and Shelbyfests and have not had an issue - YET. I contacted the aircon company who imports the pumps and they advised that the pump does not come with a 6 rib pulley, only 5 and I cannot see how the pulley can be removed. If you come up with a way of removing it and fabricating a 6 rib pulley or finding one that suits, I am in

|

Im going to remedy this issue. It's the only thing I dislike about my DSC. Once I work out what's the best way to remedy I'll let u know and you can do the same. Once I get my other projects sorted this job is next on my list. |

05-26-2015, 05:01 AM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Cobra Make, Engine: Manufactured by Me, 408 Windsor, TKO600, 3.3 Jag rear

Posts: 40

|

|

Not Ranked

Not Ranked

Look forward to the resolution and as an fyi, last Saturday I caught up with the owner of the ex Tim Hendy DSC which has a 7 litre monster in it. We went for a blast in mine and then his and what a difference those cubes make. Suffice to say I came away drooling and now that the TH car is painted, it looks as good as it goes.

__________________

Serpnt

Melbourne

|

08-16-2015, 10:43 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Not a lot of interesting progress to report. Been busy with work and jobs around the house.

Had a big rearrange in the workshop. I've paneled the other side wall and moved all the shelving from the rear of the shed to the side. During the moving I'f tried to throw out a lot of old junk that I'll probably never use. Still more junk to go. I've also put up more fluro lighting on that side of the shed and wired in a permanent power point for the hoist so I don't need to run a lead out every time.

On the Cobra I've been trying to get panels to fit correctly and the boot lid has needed some work. I fitted up the bonnet the other day only to discover the nice PS reservoir and it's mount are in the wrong spot. I miscalculated and the bracing on the underside of the bonnet hits on the top of the reservoir Grrr. So the reservoir is moving to the end of the foot box and I've had to redo some of the plumbing.

While I was looking in the engine bay I decided to sort out a few other jobs (Ones that are a lot more fun than bloody fiberglass and bodywork)

I had added a filler neck and pressure cap setup on the old water pump. It let me get rid of the header tank and gave a good spot to purge any air out of the system. Unfortunately when I had originally done it I had a pin hole in one of the welds and chases it all over trying to fix it. I decided to cut the neck off and start again. The new one turned out much neater and I'm a bit more confident of the weld. It may look a little ugly as I went over it a couple of times to hopefully ensure no pinholes. I'll grind the weld down and blend the area so it'll kind of look factory.

While I was messing with the water pump I decided it was about time to make the new pulley for it. The old original one I'd made doesn't match the smooth style PS pump pulley.

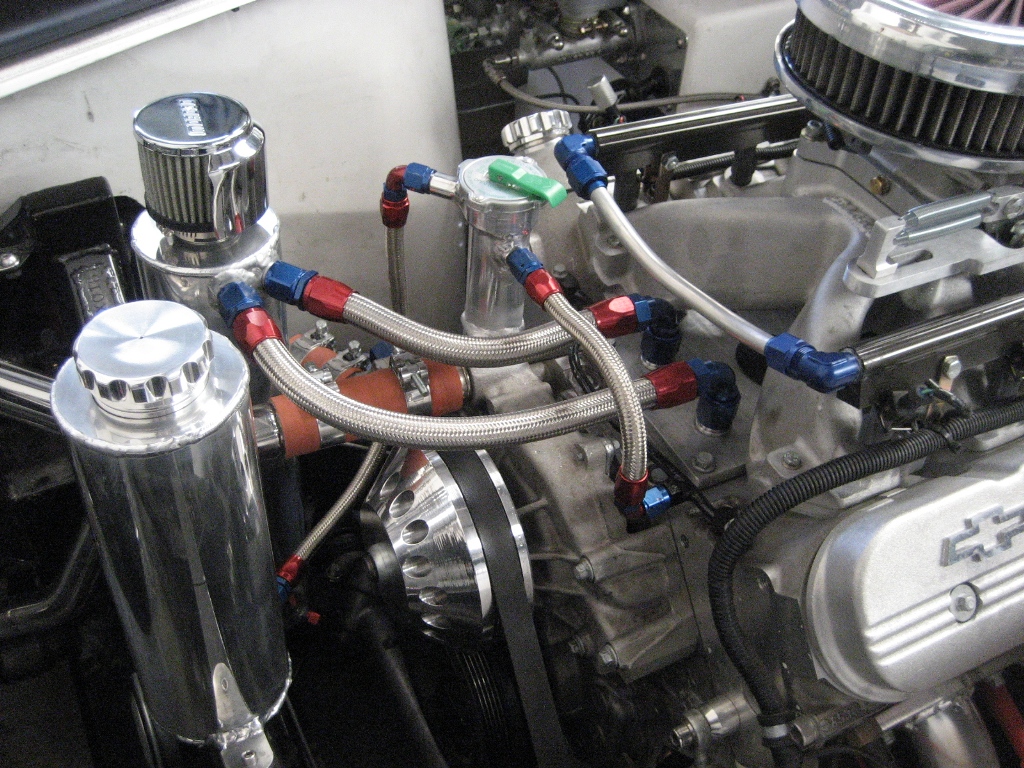

Here's the original setup

So here's the beginnings of a new water pump pulley. It starts as a 6" diameter billet of aluminum. Somewhere inside it there is a pulley. I've just got to machine away the aluminium to find it.

I cleaned the swarf tray on the lathe before I started as it'll be interesting to see how much material is removed (I'm figuring more than half of this block will end up in the tray.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-17-2015, 03:57 AM

|

|

CC Member

|

|

|

Join Date: Mar 2010

Location: Gold Coast,

QLD

Cobra Make, Engine: Arntz, TKO600, 460

Posts: 818

|

|

Not Ranked

Not Ranked

As always Mike, just freakin awesome.

However, in the interest of say......... simplicity........ could the PS pulley just not had a few holes drilled in it to match the WP pulley.

Never mind, I understand re-doing things that may not need to be re-done in the first place.

|

08-17-2015, 04:15 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Cheltenham,

Vic

Cobra Make, Engine: Classic Revival CR3516, LS3, Aussie Mike'd T-56, 3.70 LSD, AP brakes, Penske shocks

Posts: 1,616

|

|

Not Ranked

Not Ranked

Let's see pics of the shed!

__________________

BUILD-BLOG: http://cobrablog.holnet.net

Ben in AU

|

08-17-2015, 04:49 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I'll have to update the shed thread Ben

I thought about just drilling the PS pulley and I may yet but one of the things I don't like about the original water pump pulley is that the water pump snout sticks through the center of it. Kind of looked half finished to me. I also messed up my measurements on the ring of holes in that the 4 bolts that retain the pulley should have been in line with the other holes. Looks OK but always annoys me when I look at it.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-17-2015, 08:22 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

A couple of satisfying hours on the Lathe. The internal dimensions of the pulley are all done. There's a few steps in there and a radius in the corner of one of the steps. Plenty of material removed.

A test fit on the water pump confirms the dimensions. It's a perfect snug fit. No bolts required to hold it in place.

Now to grind up a tool and cut the V grooves for the serpentine belt.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-22-2015, 06:45 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Finished the water pump pulley today. Pleased with how it turned out.

Here's the pulley after machining the v grooves for the serpentine belt. I've flipped it the other way in the chuck and machined the front in the same conical style as the PS pump. I had to put a bit more angle on it though to remove a bit more material. But I think it still looks OK beside the PS pump.

After finishing the lathe work I gave it a bit of a polish. Then on to the mill to machine the bolt holes. The rotary table makes easy work of this type of job.

Here it is all bolted up. Everything fit perfectly and belt alignment is spot on. Got to remove it and polish it properly and then make up a belt tensioner setup.

So what do you reckon? Do they look too plain? Should I machine a circle of holes or kidney bean shapes or spokes in both of them?

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-22-2015, 08:48 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Melbourne,

VIC

Cobra Make, Engine: RMC, carb 347 TopLoader and Jag running gear ~ so old school I time it with an hour-glass :D

Posts: 1,293

|

|

Not Ranked

Not Ranked

I think they look fine

but.... How about machining them to look like mini Halibrands - that would look pretty groovy.

Little Three eared spinners will keep you sharp while doing a tune up

LB |

08-22-2015, 08:56 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Charlottesville,

va

Cobra Make, Engine: Coombe, Shelby Block 496

Posts: 1,187

|

|

Not Ranked

Not Ranked

Very nice work, and great skills.

Keep the pictures coming.

|

08-22-2015, 11:05 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by LoBelly

I think they look fine

but.... How about machining them to look like mini Halibrands - that would look pretty groovy.

Little Three eared spinners will keep you sharp while doing a tune up

LB |

That's one of the reasons I made them smooth in the first place. The thought of accidentally getting snagged while working on the motor was in the back of my mind.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

08-23-2015, 01:58 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Mildura,

vic

Cobra Make, Engine: FFR Coupe, 416ci of LS goodness

Posts: 2,349

|

|

Not Ranked

Not Ranked

I think your pulleys look like Madonnas Tits.

__________________

Powered by Cu

|

08-23-2015, 04:13 AM

|

|

CC Member

|

|

|

Join Date: Jun 2001

Location: munno para west,

sa

Cobra Make, Engine: absolute pace chassis #50 L98 & 6 speed auto

Posts: 1,141

|

|

Not Ranked

Not Ranked

they look good anytime you want to machine up some bling for my L 98 ls let me know

__________________

a cobra is a passion anything else is just a car

i dont care what the question is .. The answer is more power!!!

|

08-23-2015, 07:32 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Location: Gold Coast Queensland,

QLD

Cobra Make, Engine: Harrison#97 LS7 / T56

Posts: 1,682

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gav

I think your pulleys look like Madonnas Tits.

|

Gav.... I think you've had one too many Pulleys..but I see it too   |

08-23-2015, 03:21 PM

|

|

CC Member

|

|

|

Join Date: Sep 2010

Location: redcliffe,

qld

Cobra Make, Engine: venom motorsports /ls1 auto

Posts: 500

|

|

Not Ranked

Not Ranked

LOVE YOUR WORK

I'm in for a set too!!

__________________

not all your babies are your children

|

08-30-2015, 03:56 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

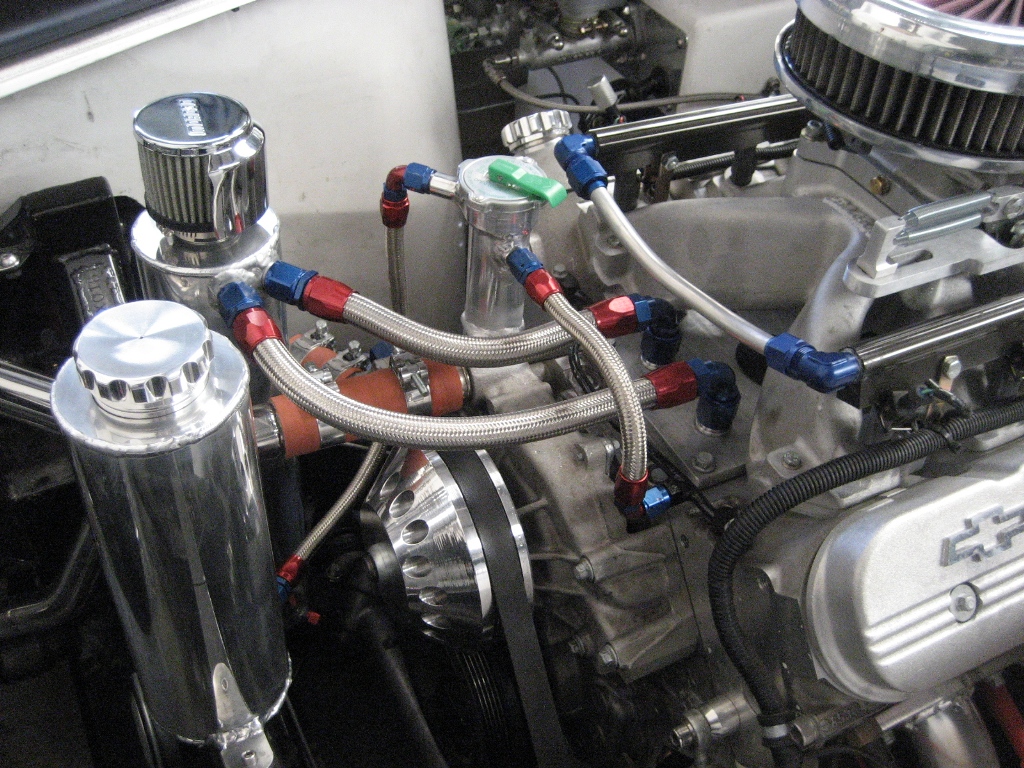

Another fun machining and fabricating job.

I made a bit of a stuff up when I set up my power steering reservoir. The top of it hit on the underside of the hood when I fitted it. The reservoir has been relocated to the end of the foot box but that left the bracket on the chassis. I didn't want to cut it off as the chassis has been powder coated so decided to find another use for it. OK I'll mount the coolant catch can there.

I looked at my original catch can. I was proud of it at the time I made it (you can see it in one of the pics above mounted of the front X member) but my skills have improved since then. I cut the top off the original and machined the the neck out so I could re-use it. I had some 100mm billet so I machined a new top and bottom out of it. This time the ends of the cap have a bit more shape and style than the flat discs originally used.

Here's a pic of the new end cap and neck welded in place on a section of 100mm tube.

Here's the bottom cap pressed in place ready to weld.

Machined up a mounting bracket that bolts to the old PS reservoir lug.

Here it is from the side. I can weld aluminium OK but I don't get those perfect stack of dimes results like the pros do. There's some wavering around where I re-position the part or myself. I've linished off the weld on the bottom end cap and I'll polish the whole thing. I'm thinking I'll linish off the top weld too but I'm in two minds. My thought is with both welds linished and the whole thing polished it'll look like it's hewn out of one solid piece. What do you reckon? Keep the weld or smooth it?

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 08-30-2015 at 04:01 AM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:36 AM.

|

|

386Likes

386Likes

Linear Mode

Linear Mode