Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

02-21-2005, 04:54 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Mechanical Guages and the LS1

Mechanical Guages and the LS1

WARNING: Long boring post about Chev engines.

I bought some Autometer mechanical guages just before Christmas. I've always liked 270 degree sweep mechanical guages as I reckon you can more easily see a change than on a 90 degree sweep elecrical guage.

Another thing in their favour is that mechanical guages are not subject to the vagaries of electrical systems. Varying voltages and suspect earths can have a significant effect on the accuracy of electical guages.

One thing not in their favour is plumbing them in. The electrical guages win hands down here. Screw in a sender and run in a wire, how easy is that! This is probably why electrical guages are so popular.

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 02-21-2005 at 05:55 AM..

|

-

Advertising

02-21-2005, 05:13 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

So having got the guages home I look at them and start wondering OK smarty pants with your mechanical guage theories, how do you hook 'em up to a motor built in the computer age??

Oil pressure is the easiest, just hook a line into a pressure feed some where and run it back to the guage. Images of hot oil squirting out from under the dash made me think a bit more carefully about this. A braided line with decent fittings is the go.

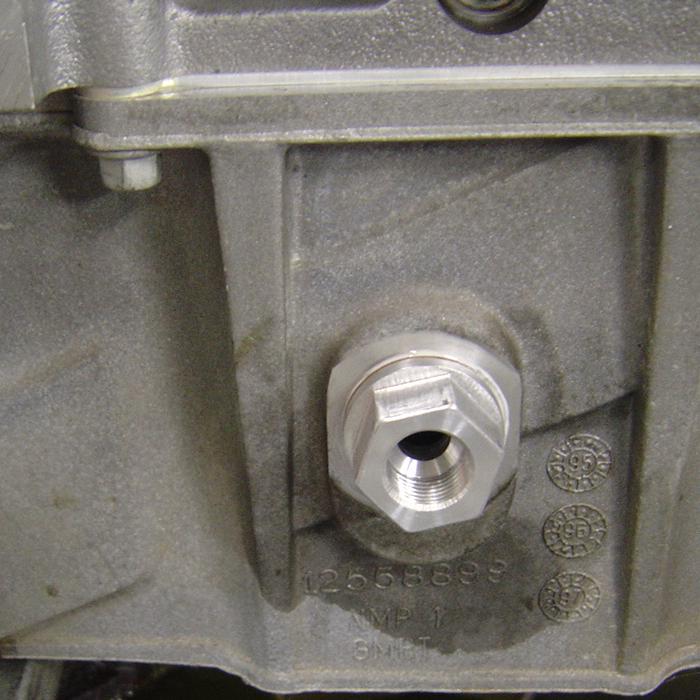

Fist thing was to find a suitable location to pick up a pressure feed from. You can usually put a T section in with your electrical oil sender for the ECU but the LS1 doesn't have your usual kinda sender or thread on it. There's a boss on the sump directly above the oil filter that looks more promising. This is a smart design on GM's part, High pressure oil from the filter comes out of the sump and goes through a bolt on U shaped section and gets ducted back into the galeries. The upshot of this is that this thing is designed with plumbing an oil cooler in mind. You can either machine up a plate to bolt on here with a couple of #8 fittings or tap the inlet and outlet holes in the sump directly. GM kindly provided a boss on the U turn plate that looks like it was made to be drilled and tapped 1/8" NPT. I used a 1/8" NPT to #3 adaptor in the hole and then made up a braided teflon line to run from the adaptor to the guage. This stuff takes enormous pressure and is very resistant to mechanical damage. The braid is also covered with a layer of plastic to stop it wearing on things.

Here's the oil pressure line:

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 05:32 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Oil temp next.

The temp guages use a capilary tube. There is a bulb on the end of the tub filled with alcohol or some similar liguad that when heated expands. This creates pressure in the capillary tube which is read by the guage.

The problem is that the bulb is quite large and the adaptor supplied has about a 7/8" NPT thread on it, it's huge. However The threaded ferule that holds the bulb into the adaptor is only a 5/8" UNF thread. This gives a few options for making my own adaptor to fit a smaller hole.

The US LS1 motors are equiped with a sump heater. This basically keeps the oil warm on freezing cold nights when the car is parked. Turn the key in the morning and the car starts easily with the warm oil being a bit thinner. The sump heater screws into boss in the side of the sump with a 20mm thread. We don't need no stinking sump heater in sunny Australia (although you have to wonder in Melbourne sometimes) So this turned out to be an ideal spot.

I machined up an aluminium do-hicky to take the 5/8" capillary bulb fitting and adapt it to the 20mm thread. A copper washer seals it against the boss and a coating of loctite liquid thread sealer adds some insurance.

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 05:41 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Water temp presented the biggest chalenge. The factory temp sender screws into the front of the passengers side cylinder head. There's a matching tread in the back of the drivers side cylinder head that's plugged. I couldn't see any other really convenient places where I'd get an accurate reading of what the tem is inside the engine.

The hole for the sender is only 12mm though so there's no way to make an addaptor to fit. This called for drastic measures i.e. attacking a perfectly good working cylinder head with a big drill and tapping it out to a larger size.

With oly one go at it I decided to make a couple of fixtures to ensure it all went in straight and in exactly the spot I wanted. I fabricated this piece to align the drill and keep it square to the face.

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 05:45 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Now with a 16mm hole drilled in the head I attached a tapping fixture to the same spot. This let me run an 18mm tap into the hole and keep everything perfectly square since the adaptor will need to seal against a copper washer.

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 05:49 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

The end result is a 18mm tapped hole in the back of the cylinder head that's square and true and in the right spot.

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 05:52 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

The adaptor is an easy job now. Machine 5/8 UNF with a 90 degree seat on the inside and an 18mm metric thread on the outside. Seal it against the head with a copper washer and some liquid thread sealer for insurance.

Cheers

__________________

Mike Murphy

Melbourne Australia

Last edited by Aussie Mike; 02-21-2005 at 05:56 AM..

|

02-21-2005, 06:15 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Mike....is the use of copper washers against that recycled beer can material normal practice?

Seems to me copper and alloy are at either end of the electrolytic scale.

Donno if thats important in this application.

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

02-21-2005, 06:30 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

I like the warning at the top Mike, But I must add that I dont find any of your posts boreing.

How could it be, it relates to chevs.

As they say, if ya wanna rev it, chev it.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

02-21-2005, 11:33 AM

|

|

CC Member

|

|

|

Join Date: Aug 2004

Location: SE Wisconsin,

Wi

Cobra Make, Engine: Arntz/SBC/Jag

Posts: 1,033

|

|

Not Ranked

Not Ranked

" As they say, if ya wanna rev it, chev it. "

I was starting to think mine was the only bow tie cobra out there...

|

02-21-2005, 07:15 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Cobra Make, Engine: 347 Stroker Morrison Injection. Registered.

Posts: 1,440

|

|

Not Ranked

Not Ranked

Yetiman,

what is a bow tie cobra?

Regards.

__________________

Mando

|

02-21-2005, 07:21 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Cobra Make, Engine: 347 Stroker Morrison Injection. Registered.

Posts: 1,440

|

|

Not Ranked

Not Ranked

Aussie Mike,

Im with Boxhead, I love seeing all the little bits and pieces that people make, especially when there made to look like factory or even better then factory parts.

It is a shame such knowledge and talent is being spent on Chevs instead of the mighty blue oval.

Regards.

__________________

Mando

|

02-21-2005, 07:40 PM

|

|

CC Member

|

|

|

Join Date: Aug 2004

Location: SE Wisconsin,

Wi

Cobra Make, Engine: Arntz/SBC/Jag

Posts: 1,033

|

|

Not Ranked

Not Ranked

Quote:

Originally posted by Mando

Yetiman,

what is a bow tie cobra?

Regards.

|

Chevy powered |

02-21-2005, 07:57 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Good point Les,

I had thought about it and had some concerns especially after Phil's radiator thread. However I've seen coper washers used on old aluminium motorcycle crank cases and head studs. I don't know if the adition of coolant will be a factor.

I can replace them with teflon later if it looks like a problem.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 07:59 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

"Bow Tie" comes from the shape of the Chevy logo. i.e. the Blue Oval versus the Bow Tie.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-21-2005, 10:10 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Uncle Mike.....I know what your up too.

You're gonna hang so much yellow metal off that thing that eventually you wont need a battery.

Now...that is a huge weight saving...sneaky you!

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

02-21-2005, 11:20 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Don't know If I could cope with being electrocuted every time I grabbed the metal shift knob.

Might have to wear a rubber driving suit. Hmmm... kinky

__________________

Mike Murphy

Melbourne Australia

|

02-22-2005, 03:02 AM

|

|

CC Member

|

|

|

Join Date: Oct 2004

Cobra Make, Engine: Classic Revival, LS1, Shift kitted auto, high stall, AU LSD rear.

Posts: 128

|

|

Not Ranked

Not Ranked

Hey Mike is your symbol with the aussie flag meant to be a concession? Ive just noticed its blue and its an oval, your not thinking of going back to the light are you????

|

02-22-2005, 03:05 AM

|

|

CC Member

|

|

|

Join Date: Oct 2004

Cobra Make, Engine: Classic Revival, LS1, Shift kitted auto, high stall, AU LSD rear.

Posts: 128

|

|

Not Ranked

Not Ranked

Nah..... just thought about your last comment about the rubber suit your definitly still with us

|

02-22-2005, 05:19 PM

|

|

CC Member

|

|

|

Join Date: Oct 2002

Location: Sydney,

NSW

Cobra Make, Engine: Classic Revival. 6 litre Chev

Posts: 669

|

|

Not Ranked

Not Ranked

Mike,

Nice work Mike. GM use copper washers on this motor under the steel bolt used to block off hole you just artfully drilled out so shouldn't be an issue. But I bet you change it anyhow

An aluminium washer would work well also.

At the track day yesterday the oil temp never got above 110 celcius with ambient temp around 29 celcius with about 40 laps completed, so it looks like then mighty Gen 111 dosent need an oil cooler. May need reconsidering if PD blower added.

Phil

__________________

COBRA 350 Powered by the Dark Side

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:22 PM.

|

|

Linear Mode

Linear Mode