Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

12-29-2008, 04:16 AM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

Drive Shaft

Drive Shaft

The Cobra is all painted and the fittings all re-fitted. Looking good!

I have measured the drive shaft for my Harrison and will get to ordering it next week. Any advice that I should know of?

Merv

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

-

Advertising

12-29-2008, 03:06 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

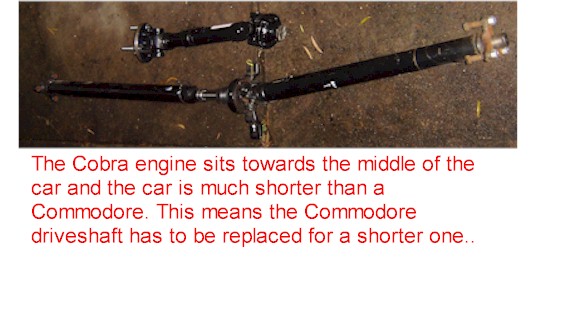

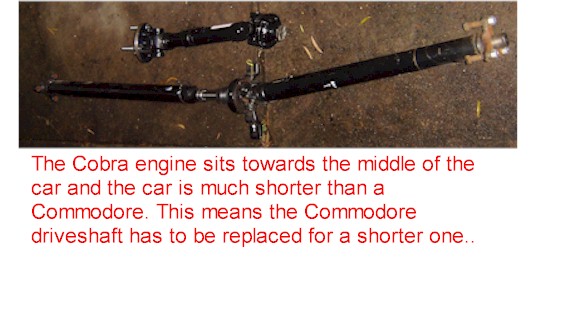

It will be short.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

12-29-2008, 03:56 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Sydney,

nsw

Cobra Make, Engine: Homebush fibreglass

Posts: 127

|

|

Not Ranked

Not Ranked

Merv

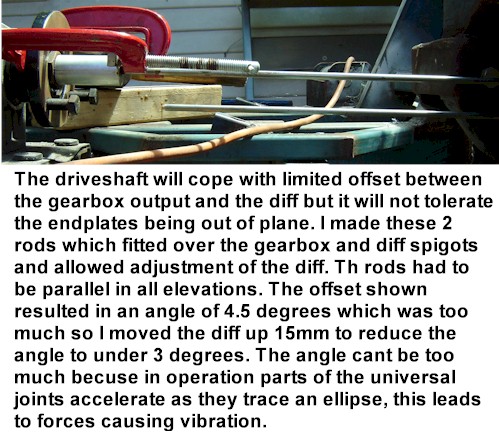

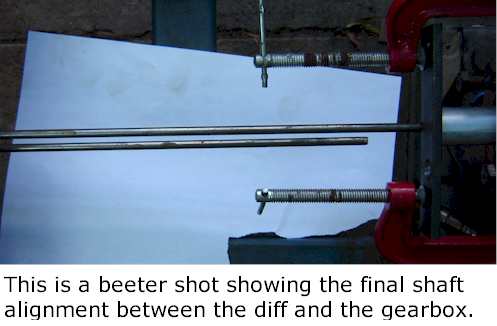

This is what I found out when I did mine. I assume yours will have 2 universal joints and a spline. Mine was made from standard joints which can be replaced when worn without having to have the whole thing re-fabricated. Also will need balancing of course. Mine has worked out well, I cannot feel vibration at any speed.

Martin |

12-29-2008, 04:00 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Sydney,

nsw

Cobra Make, Engine: Homebush fibreglass

Posts: 127

|

|

Not Ranked

Not Ranked

I should have mentioned that my rear is an IRS which means my angle stays constant, if yours is not an IRS you will need to take the range of angles into account, there are various tables and calculators on the web which relate maximum shaft RPM to allowable angle.

|

12-29-2008, 04:51 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

Merv, what was Warwick's advice? My engine/gearbox goes in soon so this thread is well timed.

Just noticed pics in your gallery of the painted car - looks fantastic!

Last edited by sambo; 12-29-2008 at 04:53 PM..

|

12-29-2008, 08:49 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Martin, are you using a jag diff?.

The jag diff pinion is offset to the drivers side by some 35mm (If I remember correctly) so did you offset the engine a little to the drivers side?.

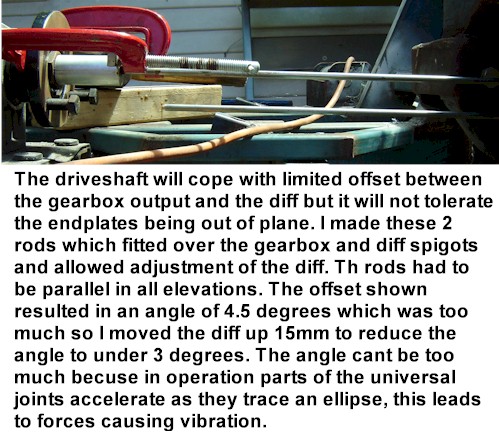

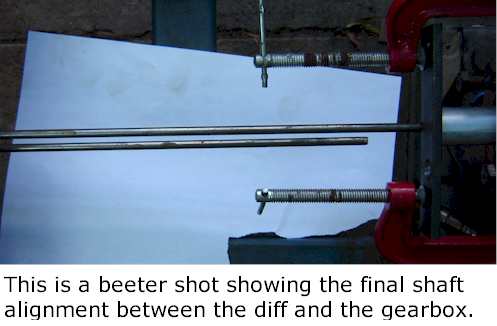

I cant tell what the separation of your two rods are in the pics.

Cheers

Les

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

12-29-2008, 11:57 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Palm Beach,

QLD

Cobra Make, Engine: Harrisons # 62 302 T5

Posts: 474

|

|

Not Ranked

Not Ranked

Square it Up

Square it Up

Merv

It is not absolutely necessary, but it might be worth your while making sure that the R32 (33?) rear is square with the T5 before you measure up. It might only make a mm or less of difference, but you will need to do it at some stage so why not now!?

I attached a straight edge (builders level) to the underneath of the car and squared it up with the back of the gearbox. I then checked it for square against the front pinion flange of the diff. I ended up having to drop the back of the R32 cradle by around 10mm.

Measuring up for the shaft is pretty simple. I took a couple of photos and annotated them with measurements (mainly diff flange to back of gearbox and protrusion of the gearbox pinion seal). Then I left the decisions as to the actual length of the shaft to the engineers.

Hope this helps

Geof

|

12-30-2008, 03:16 AM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

Lots of good advice here and thanks Sambo for the paint compliment. I am very pleased with the colour painted. I will post some more pics tomorrow as all the fittings are now back on. Tomorrow involves connecting up the clutch and accelerator cables and radiator hoses.

The Drive shaft:

Warwick said to measure it from the diff. pinion flange to the rear edge of the gearbox housing (425mm) then he will order the 'shaft made for me. That sounds fine. The rear is IRS (R32 Nissan) so I guess the angles are less critical.

However, I will check make sure both faces are square, as Martin and Geof suggest. I feel that these probably aren't, as to the eye the gearbox is actually off the horizontal already. That is, if I look at the top of the mounting plate for the gearlever, it is not parallel to the garage floor (+/_ 10 degrees). This may not be a problem as I could adjust the engine mounts a bit but it makes me think that the rear vertical face of the gearbox may also be out to some degree. Perhaps Warwick has in mind that I use a service to get it balanced. Haven't had a chance to discuss this as yet.

Merv

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

12-30-2008, 05:19 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Townsville,

QLD

Cobra Make, Engine: Harrison #77

Posts: 83

|

|

Not Ranked

Not Ranked

Merv,

I fabricated my own out of a commodore front half and nissan navara 4x4 (SD25)front shaft. had a mate balance it for me. I used the commodore tube due to its thicker wall. Total overall length was about 420mm. Only have 320mm between diff flange and gearbox. Don't forget you need to have some angle on the shaft so the uni's are moving otherwise they wear out quickly. Hope this helps.

Regards

Lionel

|

12-30-2008, 01:50 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

OK then, I am getting the idea that the vertical faces should be parallel and that the shaft itself needs to be balanced. Some degree of horizontal angle between the two is also needed for the universals to operate effectively.

Is that correct?

I will, of course, use Warwick's engineer as he has the experience with his car design.

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

12-30-2008, 02:43 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

Merv, another idea is to swap the Nissan flange for a Commodore item so that you have standard Holden parts if you ever need to replace parts in the middle of nowhere. Can't remember whose idea it was but it made sense to me.

|

12-30-2008, 03:05 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Merv and Sharon

OK then, I am getting the idea that the vertical faces should be parallel and that the shaft itself needs to be balanced. Some degree of horizontal angle between the two is also needed for the universals to operate effectively.

Is that correct?

I will, of course, use Warwick's engineer as he has the experience with his car design.

|

Yes.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

12-31-2008, 05:56 AM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

Thanks for the great info that you sent through Rob.

Merv

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

01-01-2009, 12:48 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Sydney,

nsw

Cobra Make, Engine: Homebush fibreglass

Posts: 127

|

|

Not Ranked

Not Ranked

Les

I have Commodore drivetrain including IRS.

As I recall, the engine and diff is offset (25 or 50mm?). Lionel is correct that you need some angle to prevent excessive joint wear, I think my driveshaft was about 450mm long and the angle 3 degrees.

Martin

|

01-01-2009, 05:26 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Yep, You need some offset in there to keep the needle rollers circulating in their cages. A perfectly aligned drive shaft will see the needle rollers wear grooves for themselves in the bearing cups inside the universals.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

01-01-2009, 03:18 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

That sounds good as I can't see how I could ever get it perfectly aligned!

Merv

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

01-01-2009, 06:25 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

01-01-2009, 06:39 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Sunshine Coast Qld,

QLD

Cobra Make, Engine: Harrison # 80; Ford 5.0L HO Trickflow heads, cam and rockers and MassFlow EFI

Posts: 3,482

|

|

Not Ranked

Not Ranked

Thanks Les. Good one. I am advised that the 302 and T5 'box always tilt down a little and that as long as the 2 faces are parallel then that should be OK for trialling.

Merv

__________________

Merv

Ford Cobra

Harrison #80.

Peregian Beach

Sunshine Coast Qld.

|

01-01-2009, 07:21 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Merv, This line from that site gives you the clue "ideally the operating angles on each end should be within one degree of each other"

If my trig is correct that suggests that the front of the engine can be about 35mm higher than the tail of the gearbox given a 1500mm long engine/gearbox assembly. This should set the engine at 1 degree angle from horizontal. I'm assuming your pinion angle to be at 0 degrees.

Leastwise that's how I interpret it.

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

01-01-2009, 07:49 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:14 PM.

|

|

Linear Mode

Linear Mode